| Brand | ABB |

| Model NO. | SF6-free gas-insulated switchgear for primary distribution |

| Rated voltage | 12kV |

| Rated frequency | 50/60Hz |

| Series | PrimeGear ZX2 |

Customer benefits:

Compliant with IEC standards and F-gas regulation

Compliant with IEC standards and with the EU F-gas regulation (EU) 2024/573.

High ratings up to 2500A. Single busbar modular and compact lowpressure design, based on natural origin gases (SF6 free).

Loss of service continuity LSC 2A and partition class PM*.

Reliable and flexible

Compact and modular design for space optimization.

Very low maintenance required as all high voltage parts are permanently sealed in a gas tank and protected from soiling, humidity, foreign bodies, and other environmental influences.

Due to the low-pressure design, the switchgear can remain in service up to the point of repair, even in the unlikely event of a leak.

The switchgear can be enabled with monitoring and diagnostics (e.g., temperature, gas, partial discharge) to track asset health. Automation and control features based on current and voltage sensors and IEC 61850 protocol allow for customization during the manufacturing phase and varying loads during operations.

Well known and proven vacuum circuit breaker type VD4X.

Outer cone cable termination system.

Safety

High level of operator safety with front, lateral and rear arc protection, certified AFL(R) 40kA 1s (according to IEC 62271-200).

Plug-in busbar technology and the factory-assembled pressure relief duct allows for safe, quick and easy installation at site.

With the switchgear diagram and operation controls on the front panel, no opening of the doors is required for manual operation making the switchgear operator friendly.

Wide range of monitoring and diagnostic features for safe and reliable operations. All switching devices are motor-operated and can be controlled remotely.

Mechanical and electrical interlocks prevent incorrect operation of the switchgear panels.

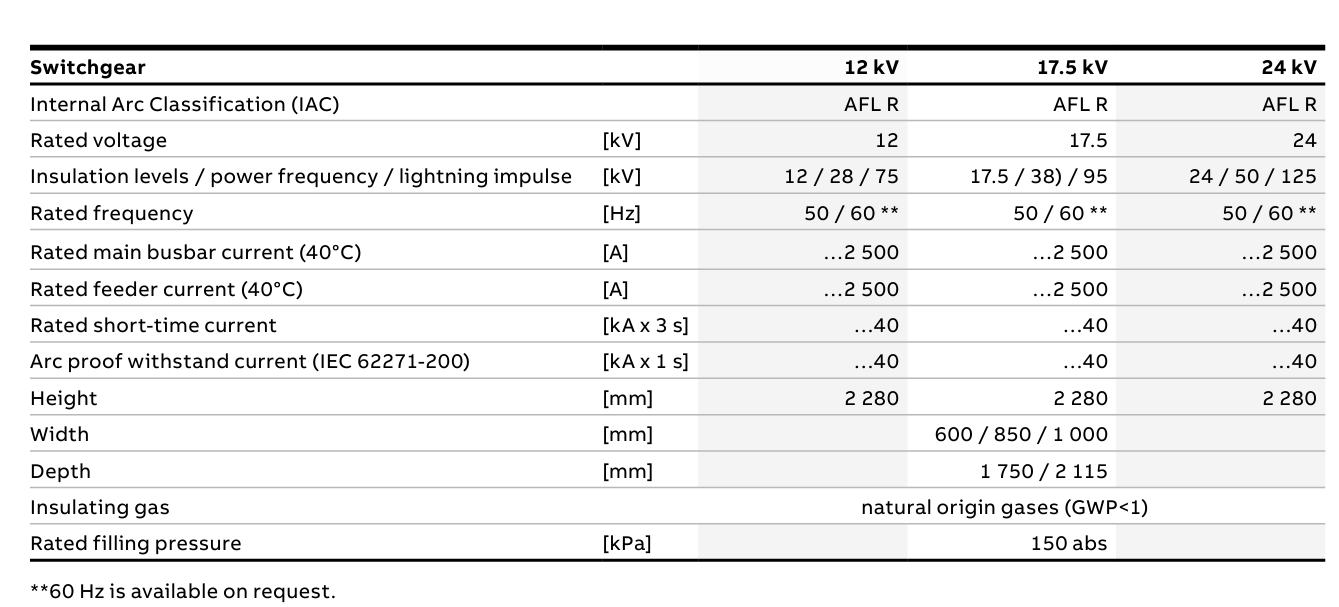

Technical parameters:

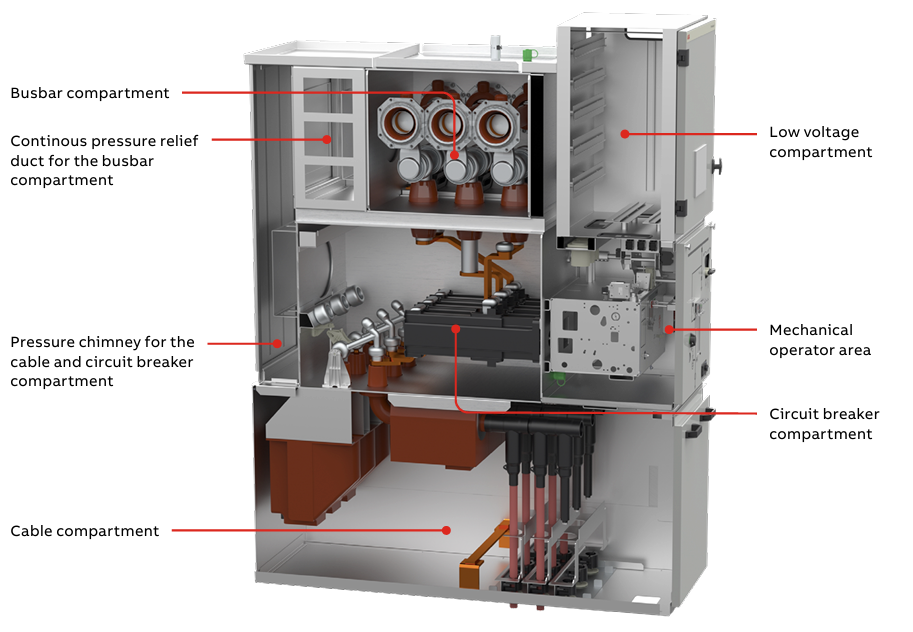

Structure diagram: