With the development of the national economy and society, the requirements for the quality and craftsmanship of power grid projects have become increasingly stringent. The need to improve the construction progress and quality of substations has created opportunities for the promotion of prefabricated cabin - type intelligent substations. The traditional on - site wiring and commissioning of secondary substation equipment involve a large amount of work. Moreover, on - site construction has to wait until the completion of professional works such as civil engineering and primary electrical engineering before commencing. This easily restricts the construction period. By using prefabricated cabin - type secondary combined equipment, the entire set of secondary equipment can be integrated by the manufacturer, maximizing engineering - based processing, reducing on - site secondary wiring. At the same time, it can also reduce the workload in aspects such as design, construction, and commissioning, simplify maintenance and repair, and effectively shorten the construction period.

1 Technical Features of Prefabricated Cabins

The prefabricated cabin has created a new substation construction mode of "standardized design, factory - based processing, and prefabricated construction", with remarkable advantages:

- Innovative Construction Mode: Reduces land occupation, saves environmental resources, lowers infrastructure costs, and significantly shortens the construction and commissioning cycles of intelligent substations, enabling rapid substation construction;

- Innovative Construction Technology: The modular design facilitates disassembly, assembly, and combination, supports quick equipment replacement, is conducive to building a maintenance component library, and reduces the investment in standby intervals; The general - purpose technology simplifies assembly, is energy - saving and environmentally friendly, improves on - site construction efficiency, and ensures project safety and quality;

- Innovative Automation Technology: Improves the intelligence level and safety reliability of substations, strengthens the industrial facility attributes, and lays a solid foundation for the green and healthy development of the smart grid.

2 Modular Secondary Combined Equipment and Its Advantages

2.1 Basic Definition

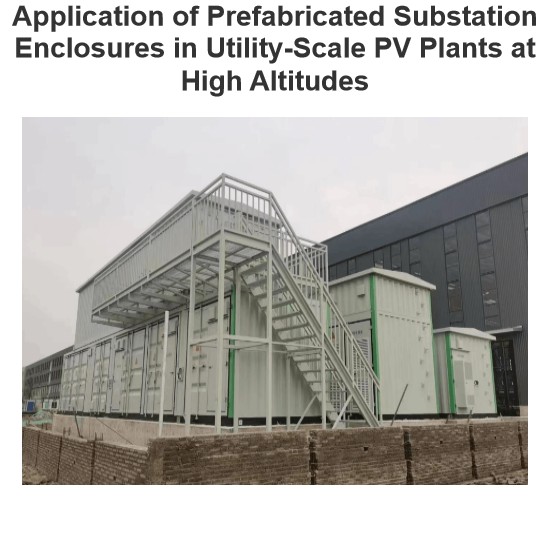

The prefabricated cabin secondary combined equipment consists of a prefabricated cabin, secondary equipment cabinets, and secondary equipment. The entire set of secondary equipment is integrated by the manufacturer, and the wiring between cabinets is completed in the factory. It is transported to the site as a whole to realize the connection with primary equipment and civil engineering. Usually, modular combination is carried out according to the characteristics of the secondary system and the primary objects it serves.

2.2 Core Advantages

The modular secondary combined equipment promotes the implementation of "standardized design, factory - based processing, and prefabricated construction". The main components of the structures are prefabricated in the factory, enabling plug - and - play of primary and secondary equipment, and creating an intelligent substation with full prefabrication and assembly. The advantages are as follows:

- Land - saving and Environmental Protection: Compared with secondary equipment rooms, it reduces the building area and land occupation, eliminates multiple on - site installation links, and reduces construction pollution;

- Efficient Integration: The secondary equipment is integrated, installed, and wired in the factory, integrating functions, improving the integration degree, saving equipment resources, reducing on - site workload, and meeting the requirements of "resource - saving";

- Optimized Commissioning: Innovates the "factory joint commissioning + on - site commissioning" mode. The factory simulates the operation scenario, completes the solidification of SCD files (such as the whole - station five - prevention logic and signal point table naming), and only needs to conduct transmission verification with primary equipment on - site;

- Simplified Design: After factory joint commissioning, a complete virtual terminal point table is generated, which can be attached to the design documents as needed to meet the requirements of dispatching in various regions;

- Cost Reduction: The secondary equipment is arranged in the distribution interval on - site, shortening the length of secondary optical cables and cables, saving materials, and reducing costs

- Construction Period Compression: Changes the serial construction to parallel construction, saving more than 60% of the on - site commissioning cycle.

3 Current Status of the Secondary System of Intelligent Substations

In the current construction of intelligent substations, the on - site installation and commissioning of secondary equipment have obvious problems:

- Process Constraints: The installation of secondary cabinets depends on the completion of civil engineering, and the optical/cable wiring of the secondary system can only be carried out after the cabinets are in place. As a result, the commissioning of the secondary system is restricted by the construction progress of civil engineering and primary equipment, prolonging the cycle;

- Low Efficiency: There are many commissioning projects and complex technologies. The after - sales personnel of the manufacturer need to be stationed on - site, which is difficult to meet the needs of large - scale promotion, and the efficiency is limited;

- Environmental Hazards: There is a lot of dust on - site, and the optical ports of secondary equipment are not well protected, affecting the performance and service life of the devices;

- Increased Land Occupation: Conventional secondary equipment requires an independent control room, occupying land resources, increasing civil engineering volume, and is not conducive to land conservation.

4 Conclusion

Compared with conventional substations, the prefabricated cabin - type combined secondary equipment has prominent advantages:

- Land - saving and Environmental Protection: Reduces building land occupation, eliminates multiple links in building construction (structure, masonry, decoration, electrical installation, etc.), reduces environmental pollution and dust impact, creates an excellent environment for the equipment in the cabin, and ensures safety and reliability;

- Efficiency Improvement and Cost Reduction: The parallel construction mode improves the efficiency of design and construction, significantly shortens the construction period; reduces on - site commissioning projects of secondary equipment. Moreover, due to the use of environmentally friendly integrated materials and on - site arrangement in the distribution interval, the length of secondary optical/cables is shortened, and the project cost is reduced.

Through technological innovation, the prefabricated cabin - type intelligent substation meets the development needs of the power grid, and has remarkable effects in cost reduction, efficiency improvement, and green construction, and has extensive promotion value.