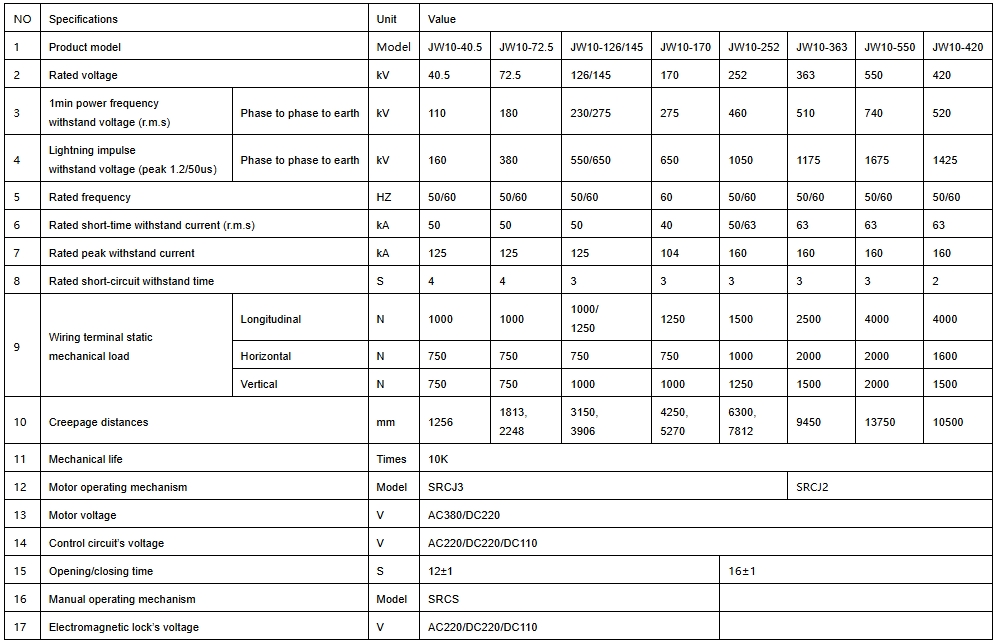

| Brand | Wone |

| Model NO. | JW10 Series Grounding Switch |

| Rated voltage | 252kV |

| Rated frequency | 50/60Hz |

| Rated peak value withstand current | 160kA |

| Rated short-time withstand current | 50kA |

| Series | JW10 Series |

Product introduction

JW10 series high voltage grounding switch is an outdoor high voltage power transmission equipment of three phase alternating frequency 50Hz/60Hz, which is used to release electrostatic charge of the inspected circuit and equipment and conduct electric sale earthing of inspected busbar and high voltage equipment’s such as breakers to make earthing opening and closing symbol visible in the circuit and guarantee the personal safety of maintenance personnel, it is generally used in places where single pole vertical fracture disconnection switch is adopted to ground the upper level busbar

JW10 series grounding switch can be attached on switch disconnector such as GW4C, GW6B, GW7B, GW22B and GW23B. it can also form independent grounding switch.JW10-40.5、72.5、126、 252 model adopts SRCC type manual operation mechanism or SRCJ3 type electromotor operation mechanism to conduct tripolar link operation.JW10-363,550 model grounding switch uses SRCJ2 type electromotor operation mechanism to conduct single pole link operation, it can also realize tripolar electric link.

The grounding switch possesses the capacity of opening and closing induction current which meeting the national standard and B Grade of the industrial standard, which is applicable to the input & output end terminal earthing of converting station of double circuit parallel overhead transmission line.

The grounding switch has possessed the national technical appraisement of new products organized by China Mechanical industry Association, The appraisement shows that the product structure and functions met the complete requirements of disconnecting switch. The product performance reaches the advanced level of world similar products.

JW10 series grounding switch is composed of three single pole and operation mechanism, Each single pole includes foundation, support insulator and earthing conducting rod. The earthing conducting rod is installed on the foundation and the fixed contact is installed on the top of support insulator.

The operation mechanism snape in or inserts in the fixed contact to realize switching on of grounding switch through driving element driving the earthing conducting rod to swing upward, The switching off operation is on the contrary.

Main characteristic

1、 The conductive arm is made of high strength aluminum alloy sections, which has good electrical conductivity, high mechanical strength, light weight and strong anti-corrosion capacity.

2、 Reliable contact structure: JW10-40 5、72.5、126、252 type grounding switch is one-step movement structure with inserted contact which is simple in structure and convenient in maintenance The structure makes effective use of electrodynamic force to intensify the contact and keep the earthing knife switch on the switching on location, which possesses good capacity of hearing short circuit current It is also in possession of the capacity of B grade induction current which meets national standard

3、 JW10-83, 550 type grounding switch is in single arm vertical & open type with inserted type contact which is simple in structure. Two-step movement is required in switching on of earthing conductive rod. When switching on, rotate the switch upward to the fixed contact and direct act to insert into the quincuncial contact. The contact is reliable and the capacity of bearing short circuit current is strong; After installing subsidiary loop and vacuum switch, its parameters of opening and closing induction current reach the domestic leading level: electromagnetic induction current: 1250A, 35kV;electrostatic induction current: 50A, 50kV.

4、 Provide one-key sequential control "double confirmation" function expansion.

Main technical parameters

Order notice

Product model, rated voltage, rated current, rated short-time withstand voltage and creep distance, etc. shall be specified when ordering Products

Arrangement method of 126-252 kV grounding switch shall be specified - parallel type or one column type;

If the grounding switch requires opening and closing induction current, special specifications and required parameters of opening and closing induction current shall be provided. The side of grounding switch which requires opening and dosing induction current of the disconnector switch shall be specified: (Ps. Only grounding switches used in the input & output circuit of converting station of two circuit parallel transmission line require the function of opening and closing induction current, which is only a minority, Not all the grounding switches and disconnect switches require opening and closing induction current.)

Model of operation mechanism, motor voltage, control voltage and auxiliary switch contact number.