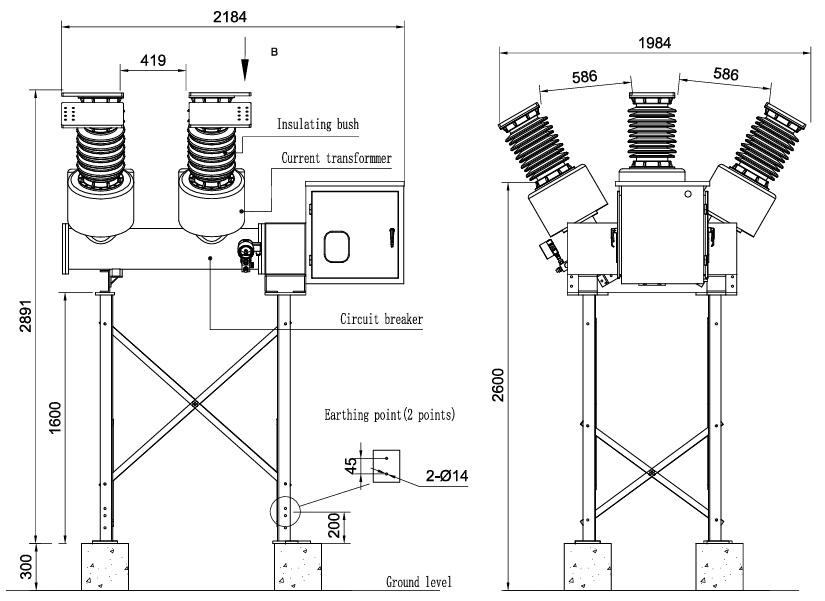

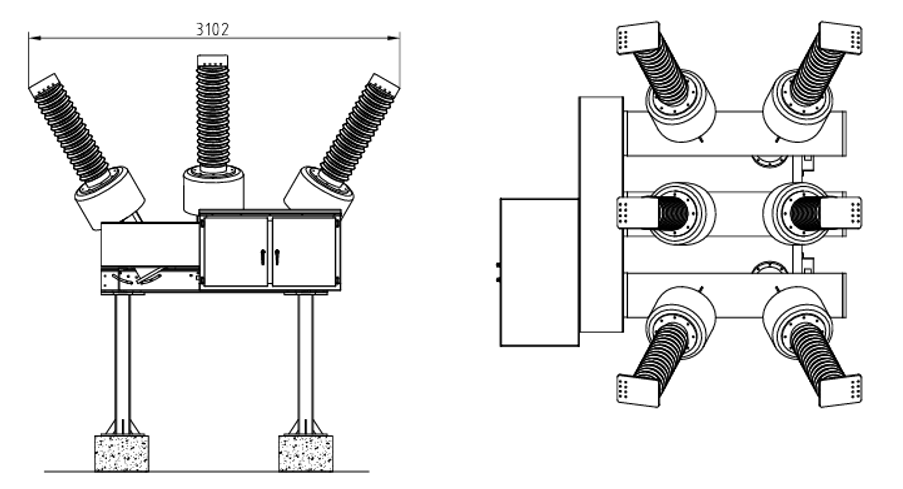

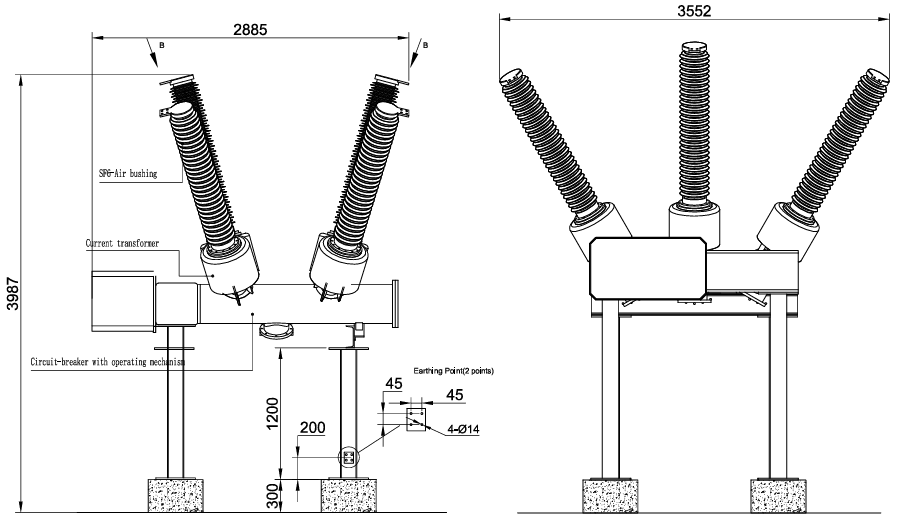

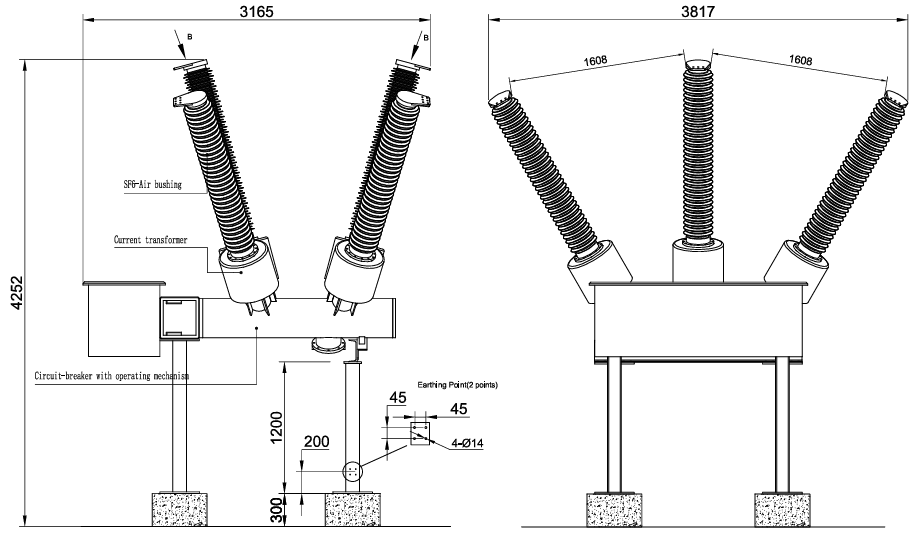

The 40.5kV, 72.5kV, 145kV, 170kV, and 245kV Dead tank Vacuum Circuit-Breakers are essential protective devices for high-voltage power systems. Employing vacuum as the arc-extinguishing and insulating medium, they boast exceptional arc-quenching capabilities, swiftly interrupting fault currents and effectively preventing arc re-ignition to ensure stable power system operation. The dead tank design offers a compact footprint and robust mechanical stability, facilitating installation and maintenance. Equipped with highly reliable spring operating mechanisms, these circuit breakers have a mechanical lifespan exceeding 10,000 operations, delivering rapid and precise responses. With outstanding environmental adaptability, they can operate stably under harsh outdoor conditions. Widely applied in substations, transmission lines, and other scenarios, they provide efficient and secure power switching control and reliable protection across various voltage levels.

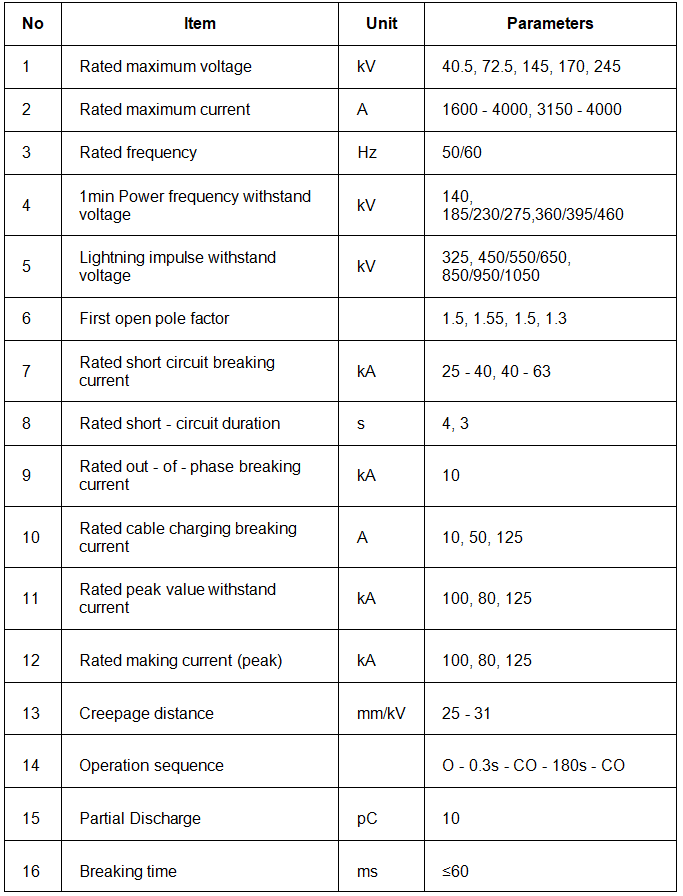

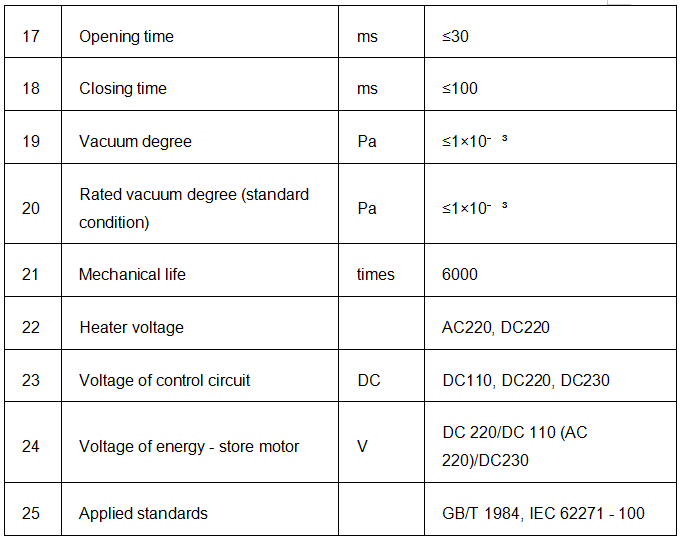

Main function introduction: