Installation and Commissioning of 10kV Dry-Type Transformers

By James, 10 Years of Electrical Equipment Maintenance Experience

Hi everyone, I’m James, and I’ve been working in electrical equipment fault repair for 10 years.

Over the past decade, I’ve worked in factories, substations, and distribution rooms of all sizes, involved in the installation, commissioning, maintenance, and troubleshooting of dry-type transformers. Dry-type transformers are among the most common electrical devices we deal with on a daily basis.

Today, a new colleague asked me:

“We just received a new dry-type transformer — how do I install and commission it? What should I pay attention to?”

This is a very practical question, especially for those who are just starting out in this field — it's like a "must-know" beginner topic. So I’ll explain everything in simple terms, based on my real-world experience over the years, so you can understand clearly and work confidently.

1. What Is a Dry-Type Transformer?

Let’s start with a quick introduction:

A dry-type transformer is an air-cooled, epoxy-resin insulated transformer, widely used in office buildings, hospitals, shopping malls, data centers — places where fire safety is important.

Unlike oil-immersed transformers, it doesn’t use insulating oil, making it safer and more environmentally friendly. However, it’s also more sensitive — especially to humidity, ventilation conditions, and installation quality.

2. What to Prepare Before Installation

Before starting the installation, preparation is key. Don’t rush into it — make sure the following points are clear:

1. Unboxing Inspection

- Check if packaging is intact;

- Confirm that product certificate, manual, and factory test report are complete;

- Verify nameplate parameters (capacity, voltage ratio, wiring group) match design requirements;

- Inspect for any physical damage, deformation, or rust;

- Ensure windings, busbars, fans, and temperature controllers are intact.

2. Environmental Inspection

- The installation site should be dry and well-ventilated, avoiding direct sunlight;

- No corrosive gases or flammable/explosive materials nearby;

- Floor is level and load-bearing capacity meets equipment requirements;

- Humidity in the switch room should ideally be below 60% to prevent insulation dampness;

- If possible, install dehumidifiers or space heaters.

3. Tools and Documentation

- Installation drawings, wiring diagrams, manufacturer technical manuals;

- Torque wrench, multimeter, megohmmeter, infrared thermometer;

- Ground resistance tester, insulating mat, personal protective equipment;

- Lifting tools (e.g., crane, hoist, lifting straps).

3. Key Steps During Installation

Here’s a standard installation process I've refined over the years:

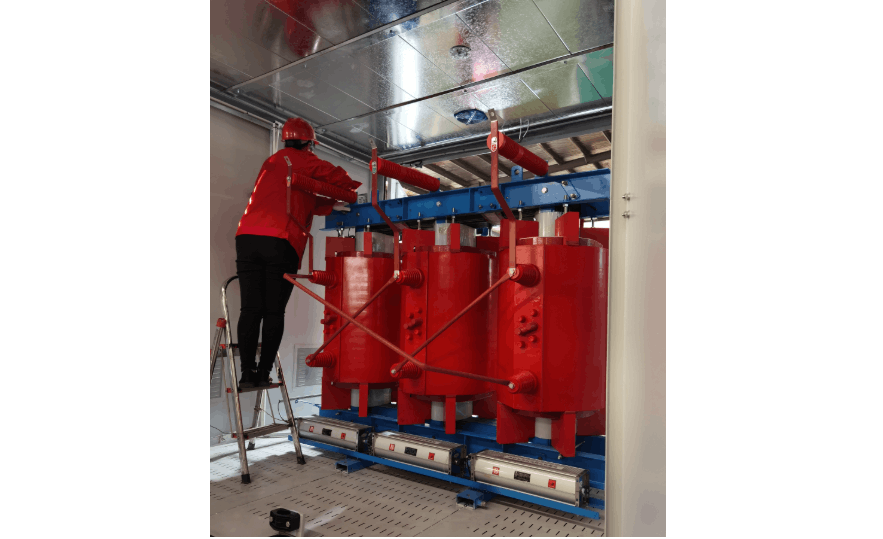

Step 1: Positioning the Transformer

- Place the dry-type transformer on its pre-prepared foundation;

- Use a level to ensure it's properly aligned;

- Tighten mounting bolts and mark them for future inspection of looseness.

Step 2: Primary and Secondary Side Wiring

- Connect high and low-voltage cables according to the wiring diagram;

- Use a torque wrench to tighten terminals per specifications;

- Ensure correct phase sequence to avoid reverse rotation or short circuits during power-up;

- Wrap exposed parts with heat-shrink tubing or insulating tape;

- Use a multimeter to check continuity after wiring.

Step 3: Grounding System Installation

- The transformer enclosure and core must be reliably grounded;

- Use copper grounding wire ≥50mm²;

- At least two grounding points connected to the main grounding grid;

- Test ground resistance ≤4Ω using a ground resistance tester.

Step 4: Temperature Controller and Fan Wiring

- Insert temperature probe into designated hole and secure it;

- Pay attention to fan motor phase sequence to ensure correct airflow;

- Set alarm and trip temperatures (typically 130°C alarm, 150°C trip);

- Test fan start/stop function.

Step 5: Cleaning and Covering

- Clean internal dust and debris;

- Double-check all fasteners are tightened;

- Close cabinet door, label with device number, capacity, and purpose.

4. Key Points During Commissioning

Installation isn't the end — proper commissioning and testing are essential to ensure safe and reliable operation.

1. Insulation Resistance Test

- Use a 2500V megohmmeter to measure insulation between windings and ground, and phase-to-phase;

- Low-voltage side insulation ≥100MΩ, high-voltage side ≥500MΩ;

- If value is low, could be due to moisture — dry and retest;

- Record R15 and R60 values, calculate absorption ratio (R60/R15 ≥1.3).

2. DC Resistance Test

- Measure DC resistance of each winding;

- Detect open circuits, shorts, or poor connections;

- Three-phase imbalance should not exceed ±2%.

3. Voltage Ratio Test

- Verify voltage ratio matches nameplate;

- Identify turn-to-turn short circuits or incorrect wiring;

- Tolerance within ±0.5%.

4. No-Load Test

- Keep low-voltage side open, apply rated voltage on high-voltage side;

- Measure no-load current and losses;

- Determine if there's core damage or local short circuit.

5. System Integration & Trial Run

- Power up temperature controller and fan control system;

- Observe normal fan startup/shutdown;

- Run under light load for at least 2 hours;

- Use infrared thermography to monitor connection temperatures;

- Ensure no abnormal heating, noise, or vibration.

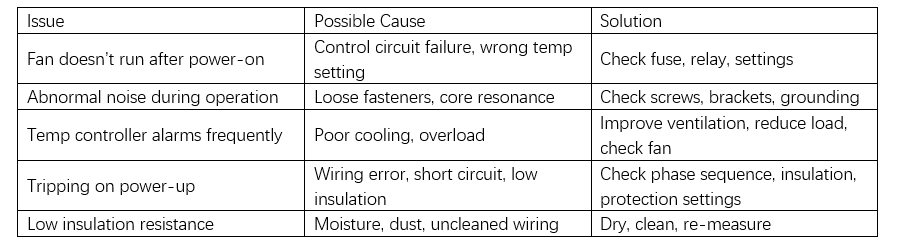

5. Common Issues and Solutions

From my field experience, here are some common issues and how to handle them:

6. My Suggestions and Experience Summary

As someone with 10 years of electrical equipment repair experience, I always say:

“Installation is the first step, commissioning is critical, and maintenance ensures reliability.”

Dry-type transformers may look simple, but their performance directly affects the stability and safety of your power system.

So here are my suggestions:

Installation Tips:

Follow manufacturer instructions and technical standards strictly;

- Pay attention to details like torque, phase sequence, and grounding;

- Better to spend an extra 30 minutes checking than to face emergency repairs later.

Commissioning Tips:

- Don’t skip any test steps, especially insulation and ratio tests;

- Keep complete records for future analysis;

- Closely monitor during trial operation and address issues immediately.

Maintenance Tips:

- Regular cleaning, especially around windings and air vents;

- Check fans, temperature controllers, and terminal blocks;

- Monitor hotspots with infrared thermometers;

- Maintain equipment logs and track performance trends.

7. Final Thoughts

Installing and commissioning dry-type transformers may sound technical, but once you understand the basic steps and precautions, it becomes manageable.

Remember this key message:

“Details determine success or failure; safety comes first.”

If you're dealing with similar issues on-site and aren’t sure how to proceed, feel free to reach out — we can work through it together and find the best solution.

May every time you close the breaker bring a smooth “click” — not a sudden “bang!”

— James

Professionalism builds strength. As an expert in the installation and operation of electrical equipment, I am proficient in the installation process and strictly adhere to standards. I skillfully master the operation essentials and can swiftly eliminate faults. With a heart that constantly explores new knowledge, I illuminate the path to the efficient operation of electrical equipment.