| Brand | POWERTECH |

| Model NO. | 344KWh Liquid Cooling ESS Solution |

| Rated capacity | 344KWh |

| Max discharge power | 0.5P |

| Series | Industrial&Commercial energy storage |

Description

The liquid cooling battery cabinet integrates battery modules with a full configuration capacity of 344kWh. It is compatible with 1000V and 1500V DC battery systems, and can be widely used in various application scenarios such as generation and transmission grid, distribution grid, new energy plants.

Features

Full configuration capacity with 8 modules with 344kWh.

Liquid-cooled battery modular design, easy to system expansion.

Intelligent monitoring and linkage actions ensure battery system safety.

Integrated heating system for thermal safety and enhanced performance and reliability.

The turnkey system is design to enhance higher efficiency and prolong battery life.

Highly integrated ESS for easy transportation and flexible O&M.

Multiple operation modes are available, the software can be customized and upgraded.

Cloud-based monitoring and operation platform supports the visit of Mysql database and multiple devices.

Application

Discharge at time of peak demand to reduce expensive demand charge.

Daytime load maximizes PV power, and excess power is stored for use at night.

Powers a facility when the grid goes down, or application in areas without electricity.

Carry out arbitrage by using peak and valley electricity prices in different time periods.

Smooth out the intermittency of renewables by storing and dispatching when needed.

Supply power at a distributed location to reduce investment in the construction of the grid.

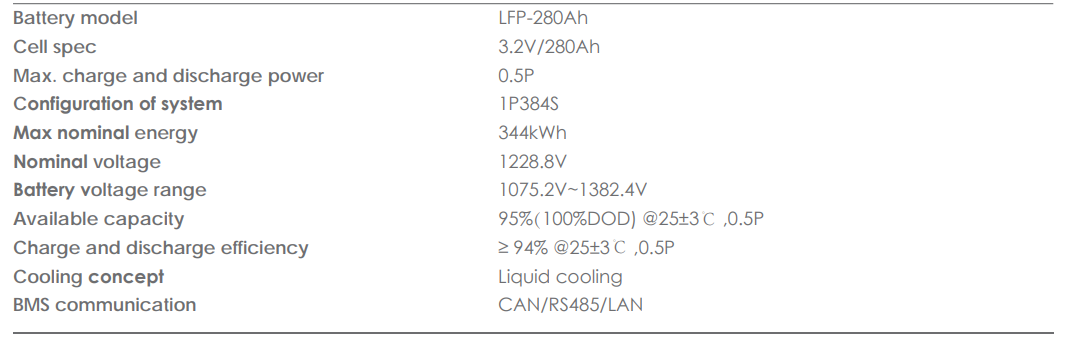

Battery date

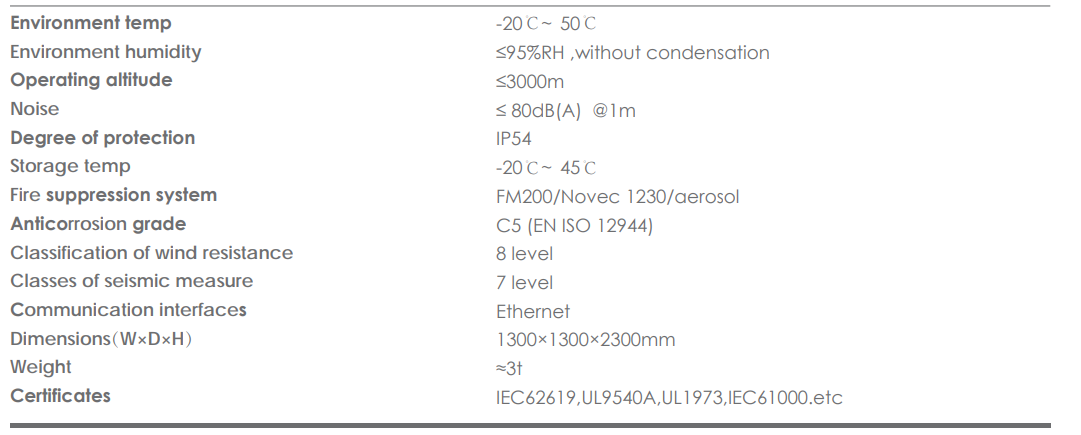

General date

How liquid-cooled energy storage solutions work?

The core of the liquid-cooled energy storage solution lies in its efficient thermal management system. This system absorbs and transfers the heat generated during the battery's operation through a liquid (usually a water-based coolant or a special coolant), thereby keeping the battery within the optimal operating temperature range and improving the battery's performance and lifespan. The following is the specific working process:

Energy storage:When the power supply is sufficient, the energy storage system converts alternating current (AC) into direct current (DC) through an inverter and stores it in the battery module.Battery modules usually adopt lithium-ion battery technologies such as lithium iron phosphate (LiFePO4), ternary material (NMC), lithium cobalt oxide (LCO), etc.

Temperature monitoring:The battery management system (BMS) monitors the temperature of each battery cell and detects temperature changes through sensors.The BMS will send temperature data to the control system so that the cooling system can be started in time.

Liquid cooling:The cooling system pumps the coolant to the cooling plates or cooling channels around the battery module through pipes.

The coolant directly contacts the battery surface or cooling plate and absorbs the heat generated during the battery's operation.

Heat transfer:The coolant after absorbing heat is pumped back to the cooling device (such as a heat exchanger, radiator, etc.) through pipes.

In the cooling device, the heat is transferred to the external environment. After the coolant is cooled again, it returns to the battery module to continue circulating.

Energy release:When power demand increases or supply is insufficient, the stored direct current is converted into alternating current through an inverter and transmitted to the power grid or directly used by users.

During this process, the liquid cooling system continues to monitor and manage the battery's temperature to ensure that the battery is in the optimal working state.