VZIMAN Prefabricated Substation Solutions for African Manufacturing Plants

1. Core Challenges in African Manufacturing Plants

1 Unstable Power Supply

Aging grids and insufficient generation capacity plague African nations. For instance, South Africa's 2023 power deficit caused 5%-10% GDP loss, while 97% of Nigerian factories rely on expensive diesel generators (annual fuel costs: $14 billion). Frequent outages disrupt production continuity and damage equipment.

1.2Weak Infrastructure

Remote areas lack transmission networks, and traditional substations require 3–6 months for deployment. Nigeria’s distribution capacity meets only 1/3 of demand.

1.3 High Operational Costs

Self-owned diesel generators have energy costs 3-5 times higher than grid electricity, with added maintenance and fuel logistics expenses.

1.4 Environmental & Regulatory Risks

Extreme climates (e.g., 55°C heat, sandstorms) accelerate equipment wear, while inconsistent regulations delay project approvals.

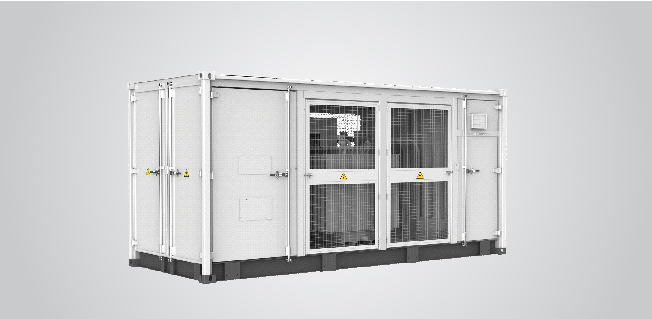

2. VZIMAN Prefabricated Substation Solutions

2.1 Rapid Deployment & Scalability

- Factory-Prefabricated + On-Site Assembly: Substations are pre-integrated in factories, reducing on-site installation to 2 weeks (70% faster than traditional methods).

- Modular Expansion: Supports "plug-and-play" capacity upgrades to match fluctuating production demands, avoiding redundant infrastructure.

2.2 Climate-Resilient Design

- Extreme Weather Protection: Q345 high-galvanized steel framework with rock wool insulation and EPDM sealing withstands 55°C heat and sandstorms.

- Grid-Independent/Hybrid Operation: Integrates solar storage to reduce grid dependency and optimize energy mix.

2.3 Smart O&M & Cost Efficiency

- Remote Monitoring Platform: Real-time tracking of load, temperature, and equipment health enables predictive maintenance, minimizing downtime.

- Energy Optimization: Dynamic reactive power compensation reduces line losses, cutting overall energy consumption by 15–20%.

2.4 Compliance & Sustainability

- Local Certification: Aligns with African standards (e.g., South Africa SANS, Nigeria SONCAP) to expedite approvals.

- Circular Design: 80% material recyclability and 90% less construction waste align with ESG goals.

3. Expected Outcomes

3.1Production Continuity:

- Annual outage duration reduced from 300 hours to <50 hours.

- Production capacity utilization increases by 30–50%.

3.2 Cost Reduction:

- 40% lower lifecycle costs, including 60% fuel savings and 35% maintenance reduction.

3.3 Faster Project Launch:

- Power infrastructure deployment time shortened from 6 months to 8 weeks.

3.4Enhanced Social Responsibility:

- Reduces carbon emissions from diesel generation, supporting Africa’s energy transition.