Technical Solution for Electromagnetic Compatibility Optimization of 10kV Distribution Transformer Products

1. The Challenges Faced

1.1 Complex Electromagnetic Interference Sources

- Diverse Types of Electromagnetic Interference

In 10kV distribution systems, power electronic equipment, switching operations, lightning strikes, and other factors generate high-frequency and pulsed electromagnetic interference. These interference signals act on distribution transformers through conduction or radiation, compromising their normal operation.

- Risk of Transformer Damage

Excessive electromagnetic interference may lead to internal insulation breakdown and control circuit maloperation in transformers, severely impacting operational stability. Mitigation measures are imperative to ensure reliable transformer performance.

1.2 High Electromagnetic Sensitivity

- Weak Anti-interference Capability of Intelligent Modules

Modern 10kV distribution transformers incorporate intelligent monitoring and control modules, including winding temperature monitors and on-load tap changers. These electronic devices exhibit extreme sensitivity to electromagnetic interference.

- Interference Impacts Transformer Operation

Electromagnetic interference on intelligent monitoring/control modules may cause inaccurate monitoring data and control function failures, jeopardizing transformer reliability and grid stability.

1.3 Shielding and Grounding Challenges

- Insufficient Shielding Effectiveness

Traditional transformer shielding structures and grounding methods struggle to suppress electromagnetic interference effectively. Conventional metallic enclosures demonstrate inadequate shielding performance against high-frequency EMI.

- Imperfect Grounding System

Suboptimal grounding systems hinder effective EMI discharge, exacerbating electromagnetic compatibility (EMC) issues. Addressing this is critical for transformer EMC compliance.

1.4 Cost-Performance Trade-off Dilemma

- High Cost of Premium Materials

While advanced EMI shielding materials and sophisticated filtering devices enhance EMC performance, they significantly increase product costs.

- Cost Constraints Impede Market Penetration

Cost escalation undermines product competitiveness and market adoption. Balancing performance enhancement with cost control is essential for sustainable development.

2. Solution

2.1 Optimized Electromagnetic Shielding Structure

- Dual-layer Composite Shielding

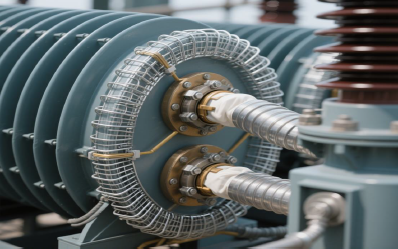

A dual-layer shielding design combines high-conductivity copper (inner layer) and high-permeability silicon steel (outer layer), effectively suppressing both high- and low-frequency EMI.

- Localized Shielding for Critical Components

Specialized shielding treatments for bushings, terminal blocks, and other vulnerable areas minimize electromagnetic leakage and enhance overall shielding efficacy.

2.2 Enhanced Grounding System

- Independent Low-impedance Grounding

A dedicated low-impedance grounding system integrates multipoint and star-type grounding configurations to ensure rapid EMI discharge.

- Independent Grounding for Key Components

Optimized grounding leads for transformer cores, enclosures, and electronic control modules reduce grounding resistance through optimized electrode selection and layout.

2.3 EMI Filter Installation

- High-efficiency EMI Filters

Install high-performance EMI filters at transformer input/output terminals, utilizing frequency-specific filtering components.

- Multistage Filtering for Interference Suppression

Multistage filtering circuits effectively mitigate conducted interference, reducing EMI impacts on transformers and adjacent equipment.

2.4 Advanced Material Selection

- EMC-optimized Materials

Select low-permittivity, high-insulation-strength materials (e.g., nano-composite insulating materials) for windings and insulators to suppress EMI propagation.

- Dual Improvement in Material Performance

These materials simultaneously enhance insulation properties and EMI suppression capabilities.

2.5 Intelligent Monitoring & Control

- Real-time Electromagnetic Environment Monitoring

An intelligent monitoring system tracks transformer electromagnetic parameters and operational status via sensors, employing big data analytics and AI algorithms for EMI prediction and early warning.

- Automatic Operational Parameter Optimization

The smart control system dynamically adjusts transformer operating parameters based on monitoring results to optimize EMC performance.

3. Realized Benefits

3.1 Enhanced EMC Performance

- Significant EMI Reduction

Post-optimization, 10kV distribution transformers exhibit markedly reduced EMI emission levels, complying with international EMC standards and minimizing impacts on peripheral systems.

- Improved Anti-interference Capability

Enhanced immunity ensures stable operation of electronic control modules, accurate monitoring data, and reinforced grid security.

3.2 Increased Operational Reliability

- EMI Shielding & Grounding Optimization

Optimized shielding and grounding systems mitigate insulation aging and faults, extending transformer service life.

- Intelligent Monitoring & Control System

Proactive fault detection and intervention through intelligent systems elevate operational reliability.

3.3 Reduced Maintenance Costs

- EMC Performance Enhancement

Improved EMC and operational reliability lower fault rates and maintenance expenditures.

- Predictive Maintenance via Intelligent Monitoring

Early fault warnings prevent catastrophic failures, further reducing O&M costs.

3.4 Balanced Cost-Performance Ratio

- Controlled Cost Escalation

Strategic material/technology selection ensures EMC improvements without excessive cost inflation.

- Competitive Market Positioning

Optimized 10kV distribution transformers deliver superior EMC performance and cost-effectiveness, strengthening market competitiveness.