Digital Twin-Driven Smart Manufacturing: Next-Gen Intelligent Solutions for Dry-Type Transformers

Digital Twin-Driven Smart Manufacturing: Next-Gen Intelligent Solutions for Dry-Type Transformers

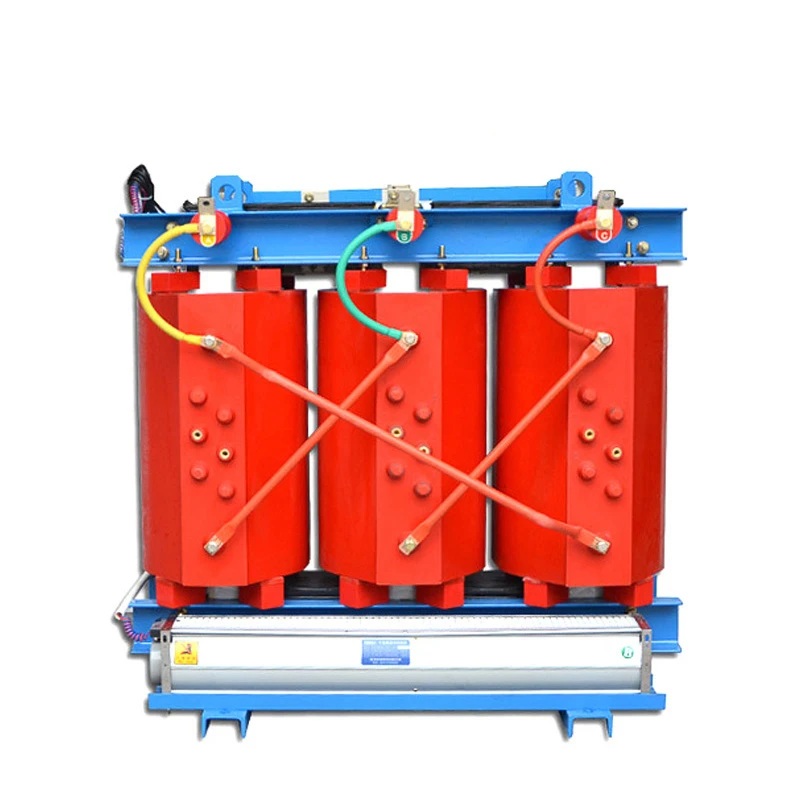

Amidst the dual waves of energy transition and smart manufacturing, Dry-Type Transformers are rapidly evolving towards digitization and intelligence. Our proposed "Digital Twin Dry-Transformer Ecosystem" integrates cutting-edge technologies to establish an intelligent, closed-loop management system covering the entire equipment lifecycle, propelling the industry into a new era of future smart manufacturing.

Core Technology Integration Solutions

- Intelligent Prognostics and Health Management (iPHM Pro)

- Multi-source Heterogeneous Sensing Network: Deploy edge-intelligent sensor clusters to collect critical indicators such as winding hotspot temperature, core vibration spectrograms, and partial discharge spectra in real-time.

- AI-Driven Failure Prediction Engine: Combines deep learning with physical mechanism models to construct the transformer's "health fingerprint." Achieves failure warning accuracy exceeding 92%, increases maintenance response efficiency by 40%, and reduces unplanned downtime by 50%.

- Digital Twin Mirror: Creates a high-fidelity virtual replica to simulate insulation aging and electromagnetic stress changes under actual operating conditions, enabling a transition from "predictive maintenance" to "preventive optimization."

- AI Energy Efficiency Optimization Hub (EcoOptim AI)

- Dynamic Voltage Regulation Algorithm Library: Utilizes reinforcement learning models to dynamically select the optimal tap position based on real-time load fluctuations (±5% accuracy), grid voltage quality, and ambient temperature/humidity parameters (empirically proven electricity savings of 2.8%-5.2%).

- Loss Cloud Optimization Platform: Synchronously analyzes copper/iron loss composition and load curves to generate customized economic operation strategies, achieving an annual comprehensive energy efficiency improvement rate exceeding 3.5%.

- Blockchain-Powered Trusted Carbon Footprint Platform (GreenChain)

- End-to-End Data On-Chain: Employs lightweight IoT devices + blockchain nodes to achieve immutable recording of carbon data throughout the entire process – from silicon steel/epoxy resin procurement, production energy consumption, transport mileage, to decommissioning and recycling.

- Zero-Knowledge Proof Verification: Enables third-party verification of carbon footprint authenticity using zk-SNARKs technology, meeting ESG audit requirements with 100% traceability of carbon emissions data.

- Green Credits Incentive: Automatically generates carbon reduction certificates based on on-chain data for access to carbon trading markets to secure additional revenue.

Digital Twin Ecosystem Operational Logic

Physical World Sensor Data → Edge Computing Node Preprocessing → Real-Time Mapping on Digital Twin →

AI Hub (PHM + Energy Optimization) → Optimization Instructions Fed Back to Physical Device || Blockchain Data Synchronously Recorded

Customer Value Matrix

|

Dimension |

Traditional Solution |

This Digital Twin Solution |

|

Failure Downtime Cost |

Avg. Annual Loss ≥ $50k |

Reduced by 65% |

|

Energy Efficiency |

Fixed Tap Position Adjustment |

Dynamically Optimized, Saves ≥3% |

|

Carbon Management |

Manual Reporting, Questionable Credibility |

Full-Chain Traceability, Complies w/ ISO 14067 |

|

Asset Lifespan |

Design Lifespan 20 Years |

Predicted Life Extension 15%-18% |

Implementation Path

- Phase 1: Deploy edge sensing network + basic twin model (6-8 weeks)

- Phase 2: Integrate AI optimization algorithms and blockchain nodes (4 weeks)

- Phase 3: System integration testing and operator VR training (2 weeks)