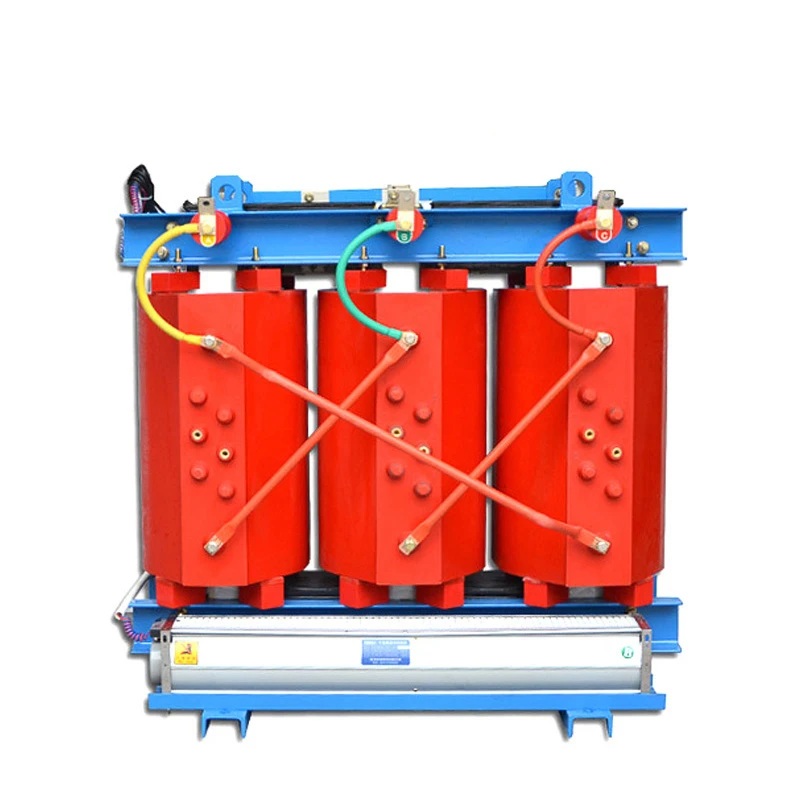

Wind/Solar PV Dedicated Dry-Type Transformer Solution

Precisely Solving Pain Points: Tackling Harsh Conditions of Renewable Energy Power Plants

The inherent intermittency and volatility of wind and PV power plants translate into critical challenges for the grid:

• Harmonic Pollution: Inverters and converters generate abundant high-order harmonics, accelerating equipment insulation aging and triggering overheating risks.

• Voltage Fluctuations: Extreme variations in sunlight/wind speed cause frequent voltage swings (up to ±10%) at the plant outlet, threatening grid connection stability.

• Maintenance Difficulties: Widely distributed sites with harsh environments render traditional offline detection methods slow-response and costly.

Customized Design: Engineered for Renewable Resilience

This dry-type transformer employs deep reinforcement design to withstand harmonic and voltage fluctuations, ensuring grid reliability:

- Superior Harmonic Resilience:

Core Design: Features K-Factor=13 high-strength solution (far exceeding the standard K=4), meaning winding designs endure 13 times the thermal effects of fundamental-frequency harmonics.

Performance Guarantee: Withstands harsh conditions with total harmonic distortion (THD) ≤8%, eliminating overheating, vibration, noise, and lifespan degradation caused by harmonics. - Ultra-Strong Grid Adaptability:

Broad Voltage Regulation: Tap range reaches ±4×2.5% = ±10% (equivalent to 0.9 pu ~ 1.1 pu nominal voltage), maintaining stable output within standard range during grid voltage fluctuations to avoid off-grid risks. - Proactive Health Monitoring:

Online DGA Integration: Built-in Dissolved Gas Analysis (DGA) unit tracks real-time generation rates of key insulation decomposition gases (CO/CO₂).

Early Warning: Detects early-stage insulation degradation signs, shifting fault detection from passive shutdowns to proactive interventions—significantly enhancing equipment availability and safety.