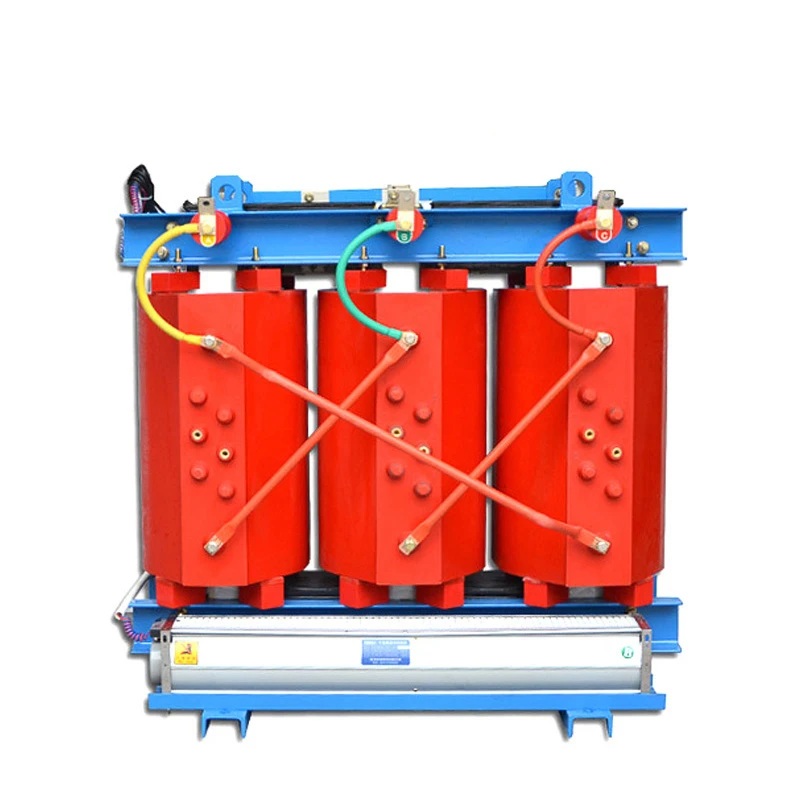

Technical Solution: RW Series Vacuum Pressure Impregnation (VPI) Dry-Type Transformers

Technical Solution: RW Series Vacuum Pressure Impregnation (VPI) Dry-Type Transformers

I. Core Technological Innovations

- Defect-Free Insulation System

- Utilizes Vacuum Pressure Impregnation (VPI) process to cast high-density epoxy resin, achieving void-free solidified insulation.

- Partial discharge levels stably controlled at <10 pC (IEC 60076-11 standard).

- Insulation thermal class reaches Class H (180°C), with insulation performance degradation rate ≤5% throughout the lifespan.

- Robust Environmental Adaptability Structure

- Integrated casting and sealing technology, achieving IP54 protection (resists persistent dust ingress and water splashing from all directions).

- Flame-retardant grade F1 (per GB/T 2207 standard testing, no sustained combustion under 900°C open flame).

- Wide operating temperature range: -25°C to +40°C (no derating required in areas at ≤1000m altitude).

- Energy Efficiency Optimization Design

- ≥15% reduction** in no-load losses for SCBH15/SCB14 series compared to GB 20052 energy efficiency standard.

- Measured data (1000kVA): No-load loss ≤0.40kW, Load loss ≤7.8kW.

- Dynamic load loss optimization technology, achieving efficiency ≥98.5% within the 35%~100% load range.

- Intelligent Maintenance System

- Embedded PT100 platinum resistors in windings (IEC 60751 Class A accuracy, temperature measurement error ±1°C).

- Supports Modbus RTU/TCP protocols. Enables via IoT gateway:

- Real-time winding hot-spot temperature monitoring.

- Three-phase unbalance analysis.

- Dynamic load-rate energy efficiency assessment.

II. Scenario-Based Application Advantages

|

Application Scenario |

Core Problem Solved |

Technical Implementation Path |

|

General Industry |

Metal dust erosion; Frequent equipment starts/stops |

IP54 housing seal + VPI pollution-resistant structure |

|

Commercial Complexes |

Stringent fire codes; Compact space |

F1 flame-retardant grade + Compact design (28% footprint reduction) |

|

Data Centers |

Harmonic pollution (THDi ≤8%); Require 7×24 stable power |

Anti-harmonic magnetic circuit design + ±2°C temperature control accuracy |

III. Life Cycle Cost Optimization

|

Parameter |

Oil-Immersed Transformer |

This Solution |

Benefit Comparison |

|

Maintenance Cycle |

Every 2 years |

Maintenance-free |

Saves ¥40k/year in maintenance |

|

Failure Rate |

0.8 per 1000 units/year |

0.2 per 1000 units/year |

60% reduction in downtime losses |

|

Residual Value (20 yrs) |

30% |

55% |

25% increase in asset value |

|

Total Cost of Ownership |

Benchmark |

30% lower |

|

|

(Validated by TCO Model) |

IV. Engineering Validation Data

- Accelerated Aging Test: Continuous operation for 5000 hours at 40°C/85% RH; Insulation resistance maintained ≥1000 MΩ.

- Seismic Performance: Passed Class II seismic test per GB/T 13540 standard (horizontal acceleration 0.3g).

- Noise Control: ≤55 dB(A) noise level during operation at 1000kVA load (measured at 1m distance).