| Brand | Schneider |

| Model NO. | WS-G 12~40.5kV AC metal-enclosed gas-insulated switchgear |

| Rated voltage | 40.5kV |

| Series | WS-G 12~40.5kV |

Summary

WS-G Safe Reliable Environmentally friendly

Schneider Electric’s gas-insulated switchgear WS-G has very high safety and reliability, which can ensure the continuous and stable operation of the power system and the personal safety of operators. It also has a user-friendly operation interface, which is easy for on- site operators to operate. WS-G switchgear fully complies with the latest environmental requirements.

WS-G Simple Innovative Economical

WS-G is perfectly suitable for public and industrial power distribution networks, infrastructure engineering, mining, metallurgy, petrochemical, fuel gas, railway power supply, container bases and marine industries.

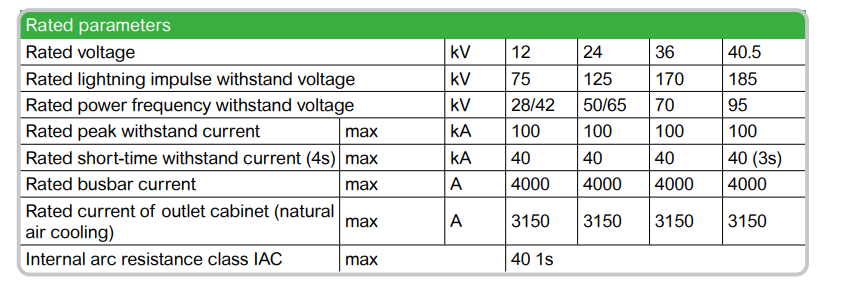

The WS-G uses a modern and innovative switchgear design concept and has a variety of options to choose from. It is a gas-insulated switchgear with rated voltage up to 40.5kV, rated current up to 3150A, and rated breaking current up to 40kA.

The WS-G is designed for single busbar or double busbar system. This compact, modular switchgear is extremely flexible and maintenance-free for its lifetime. It is also very suitable for places where space is limited or where old switches are retrofitted with existing foundations.

WS-G is an economical switch that can be spliced from the front of the switchgear when installed, extended, and removed. Thanks to the innovative busbar connection B-link, no gas handling operations are required on site.

WS-G has been tested in accordance with IEC standards, European EN standards and Chinese GB standards, as well as other national standards.

User Benefits

No gas handling required for expansions and cabinet replacement

Innovative, fault-resistant busbar connections

Friendly operation interface

Operational reliability and safety of personnel handing

Low lifetime costs

Environmentally friendly and easy to recycle

WS-G benefits and improvements

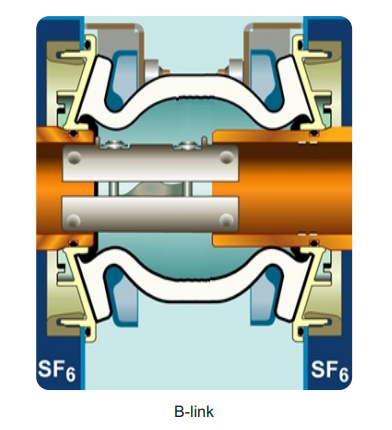

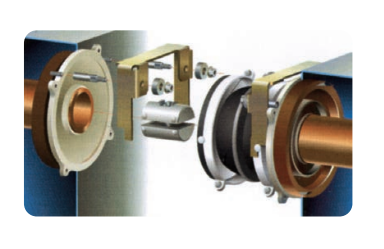

Innovative B-Link improves busbar connection

The busbar of each ws-g switchgear is installed in an independent inflatable chamber according to the system requirements. They are integrated into the insulating gas monitoring system and are not affected by the external environment. The connection with the adjacent switch cabinet bus is through our innovative bus connection system: B-link connection.

The B-link connection system does not require any maintenance.It is easy to install at the user’s site and does not require gas treatment.When expanding or replacing the switchgear, no gas handling is required and the gas chamber is not affected.The B-link connection system does not require any maintenance. It is easy to install at the user’s site and requires no gas handling. When expanding or replacing the switchgear, no gas handling is required and the gas chamber is not affected. The voltage control technology, housing grounding, soft and durable silicone rubber insulation used in the B-link connection system make the connection of the switchgear easier and the electric field distribution more uniform.

Further advantages of the B-Link system include:

All silicone rubber insulation parts have been installed on the switch cabinet in the factory, and partial discharge test has been conducted.

The on-site installation of B-link system is visible. When the B-link connection system of the adjacent switch cabinet is disassembled, an insulation distance is formed between the separated busbars without gas treatment. If necessary, the resistance of each section of busbar can be measured separately for the entire busbar system or one switchgear.

Reducing space requirements and improving space utilization

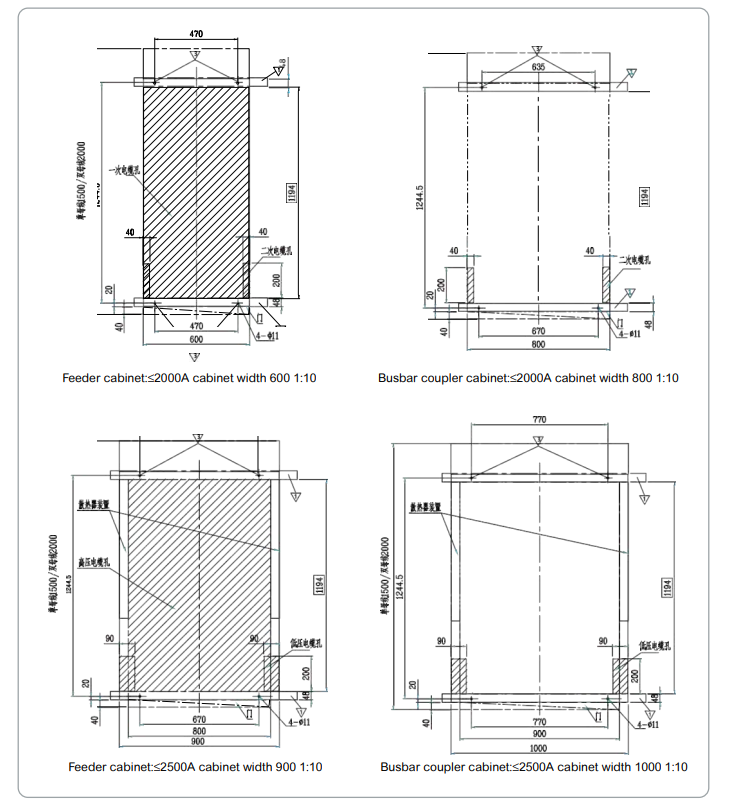

The WS-G saves investment costs due to its small space footprint.The WS-G can replace the old switchgear in the existing power distribution room.When the existing switchgear is dismantled, the WS-G can be debugged in sections. Reduce power outages.

The WS-G is designed for standard wall mounting. It does not require installation channels. All operations and maintenance procedures can be done in front of the cabinet.

Freestanding mounting options is also available.

Improved switchgear management - no gas handling required on site

The ws-g does not require gas treatment for installation or expansion in the field. All inflatable chambers delivered to the site for installation have a rated inflation pressure. All inflatable chambers have been tested for leakage prevention in the factory.

No gas treatment is required for the installation and renewal of the switch cabinet on site, and it does not affect the plenum.

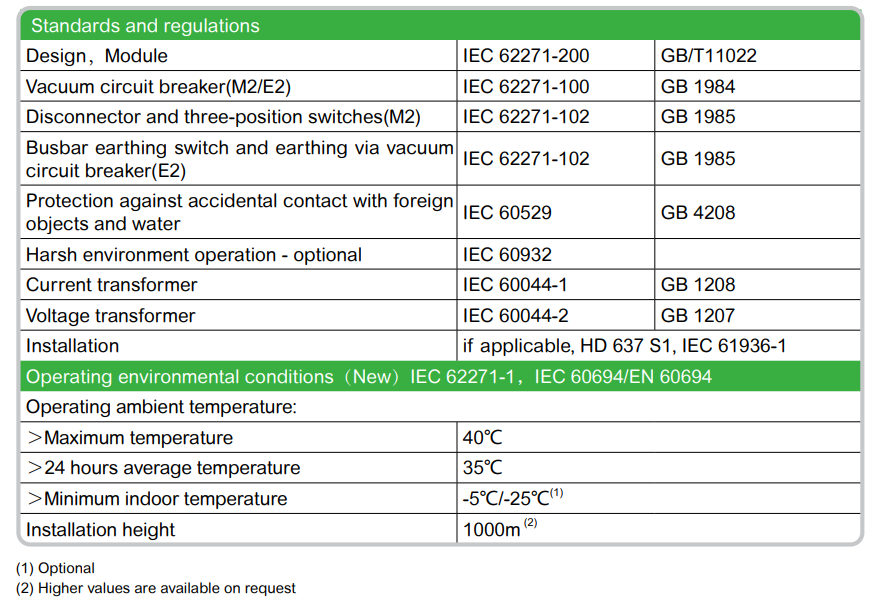

Operating conditions and technical characteristics

Surrounding environment and working conditions

WS-G series switchgear is recommended to operate under normal working conditions in accordance with IEC62271, GB11022/T and GB 3906 standards.

Technical characteristics

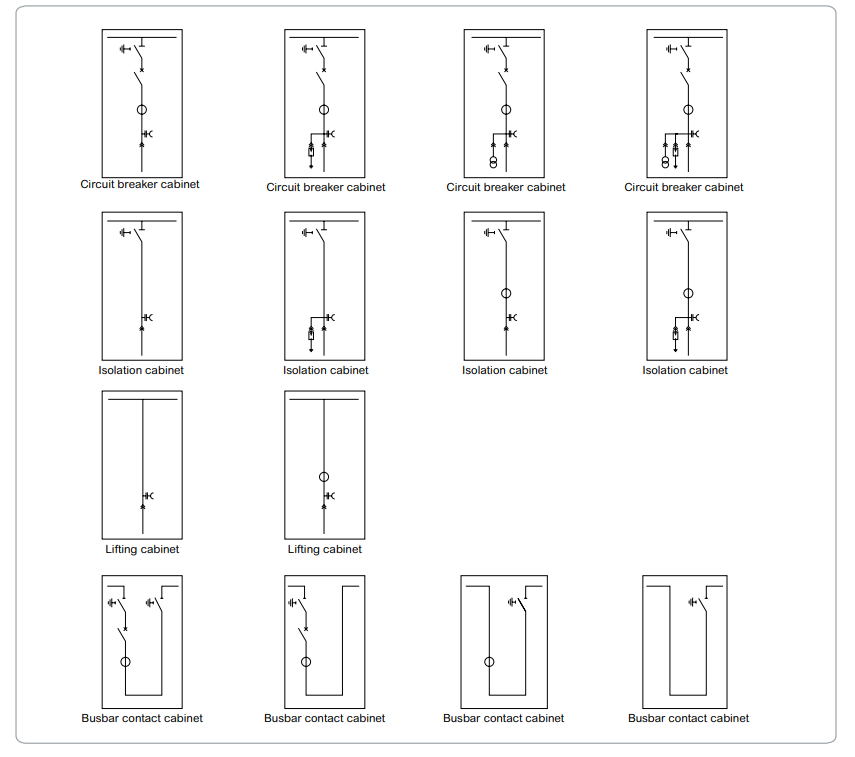

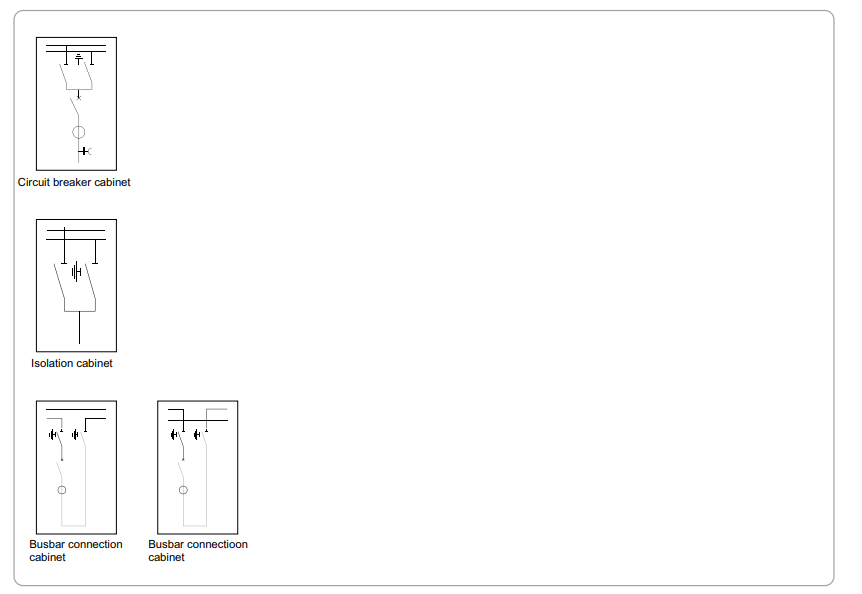

WS-G main wiring scheme

Typical scheme

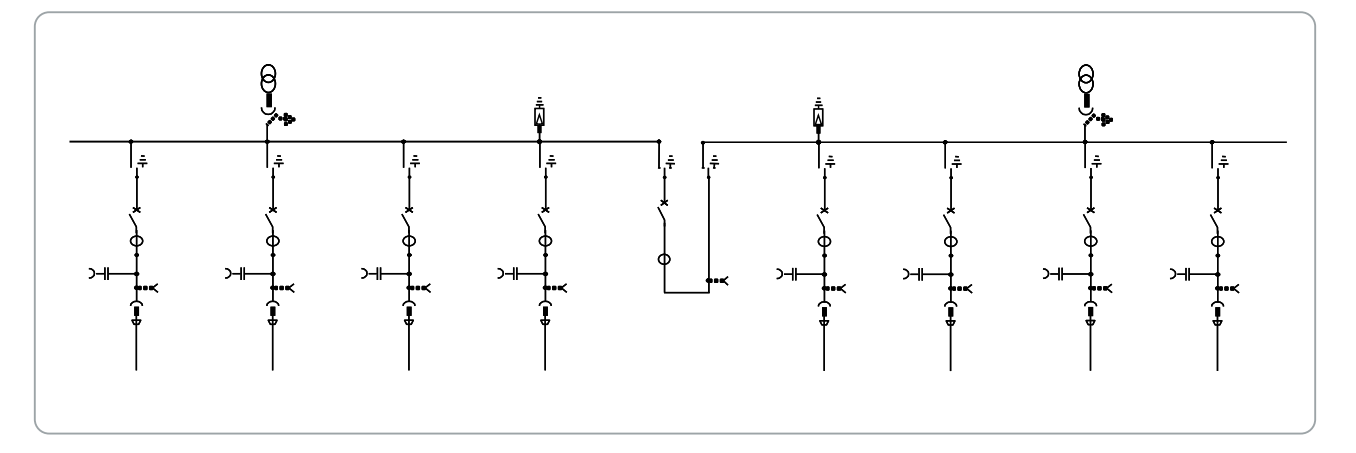

Single busbar system

Typical scheme

Dual busbar system

Typical scheme

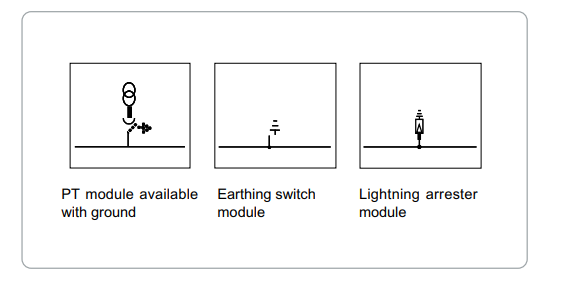

Busbar auxiliary module

Cabinet arrangement (Single busbar segmentation)

WS-G application example

Spatial distribution map of civil engineering