| Brand | ROCKWILL |

| Model NO. | 12kV, 17.5kV, 24kV available to 36kV Indoor Vacuum Circuit Breaker |

| Rated voltage | 24kV |

| Rated normal current | 1600A |

| Rated frequency | 50/60Hz |

| Series | VSC |

VSC medium-voltage indoor vacuum circuit breaker is applicable for three-phase AC power system of rated voltage up to 7.2kV~24kV and frequency 50/60HZ,widely used in many fields such as power plant, transformer substation, petrol chemical industry, metallurgy, manufacturing industry, airport, residential area, etc., to control and protect the electric equipment, especially, It is used for the occasion that needs infrequent operation at rated current or multi-breaking short circuit current, may be mounted in the indoor air insulating switchgear like type KYN28 or KYN96, ABB type ZS series, etc. This circuit breaker is standards as GB1984-2003 AC high voltage circuit breaker,JB3855 3.6-40.5Kv indoor AC High voltage circuit breaker,DL/T403 Specification of 12-40.5Kv indoor High voltage vacuum circuit breaker for order as well as IEC60694.

This circuit breaker is made with mature APG technology. The application of VSC terminal buffer guarantees the indoor terminal is ever more reliable in nay operation environment. VSC can fully meet the requirement of GB, DL, IEC, DIN, VDE as well as standards of other advanced industrial countries.

Service environment

Air temperature: Maximum temperature: +40℃; Minimum temperature:-25℃

Humidity: Monthly average humidity 95%; Daily average humidity 90% .

Altitude above sea level: Maximum installation altitude: 2500m

Ambient air not apparently polluted by corrosive and flammable gas, vapor etc.

No frequent violent shake

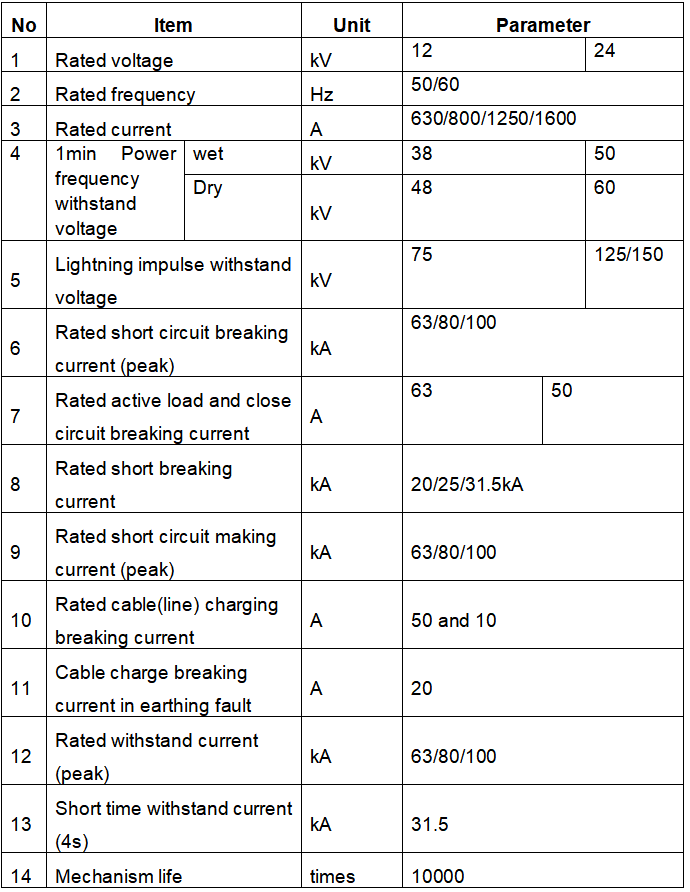

Main technical specifications

Note:For short circuit breaking current & rated current is optional by clients.

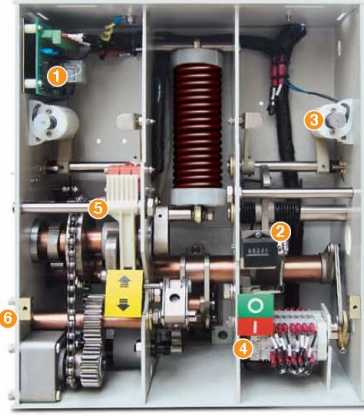

Structure & characteristic

1) Wiring board for income line secondary

2) Counter

3) Closing coil

4) Auxiliary switch 8NO,8NC is optional

5) Charging chain

6) Motor

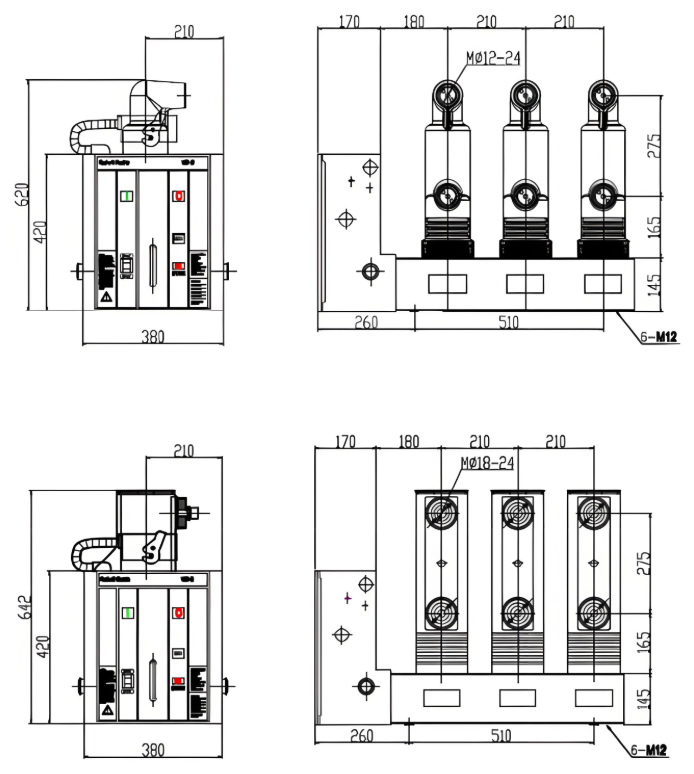

Installation sizes& outline dimensions