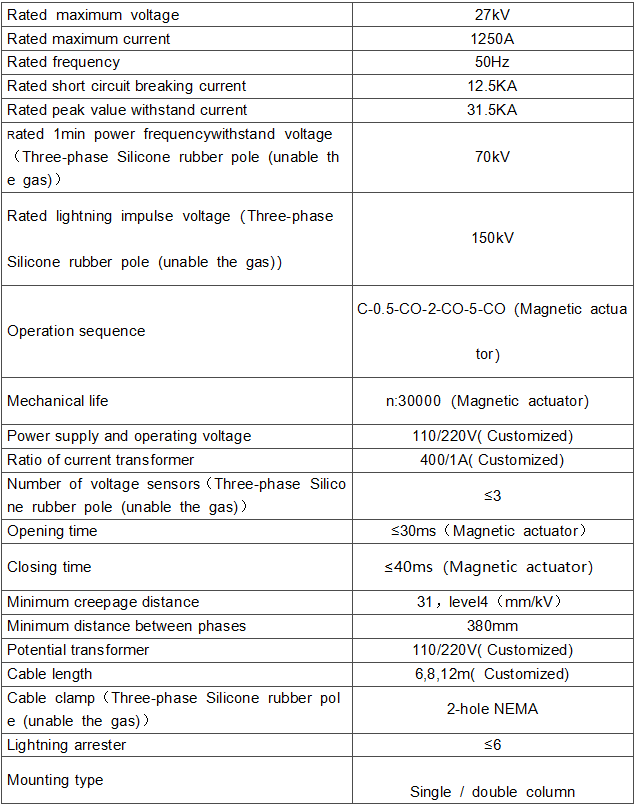

| Brand | ROCKWILL |

| Model NO. | 27kV MV outdoor Auto Circuit vacuum recloser |

| Rated voltage | 27kV |

| Rated normal current | 1250A |

| Rated short circuit breaking current | 25kA |

| Power frequency withstand voltage | 70kV/min |

| Rated lightning impulse voltage | 150kV |

| manual closing | No |

| Mechanical lock | No |

| Series | RCW |

Description:

The RCW series automatic circuit reclosers can use on overhead distribution lines as well as distribution substation applications for allvoltage classes 11kV up to 38kV at 50/60Hz power system. and it’s rated current can reach 1250A.The RCW series automatic circuit reclosers integrates the functions of control, protection, measurement, communication, fault detection, on-line monitoring of closing or opening.The RCW series vacuum recloser is mainly combined with integration terminal, current transformer, permanent magnetic actuator and it’s recloser controller.

Features:

Optional grades available in rated current range.

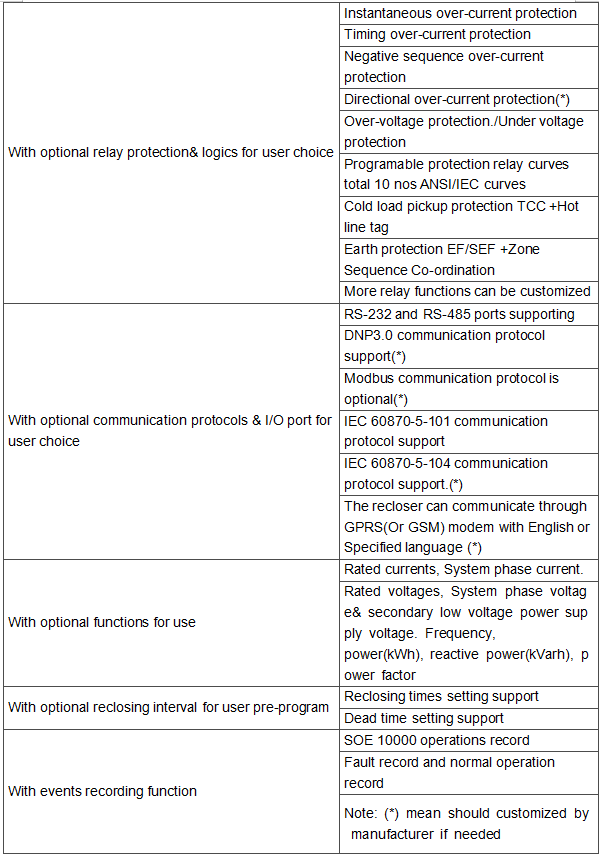

With optional relay protection and logic for user selection.

With optional communication protocols and I/O ports for users to choose.

PC software for controller testing, setup, programming, updates.

Parameters:

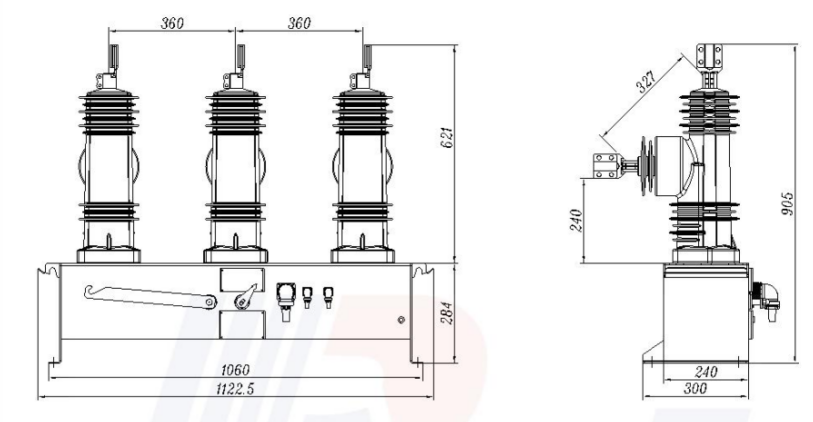

External dimensions:

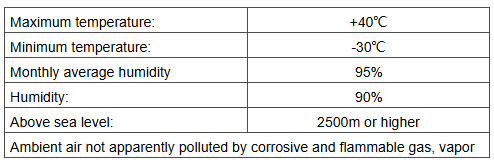

Environmental requirement:

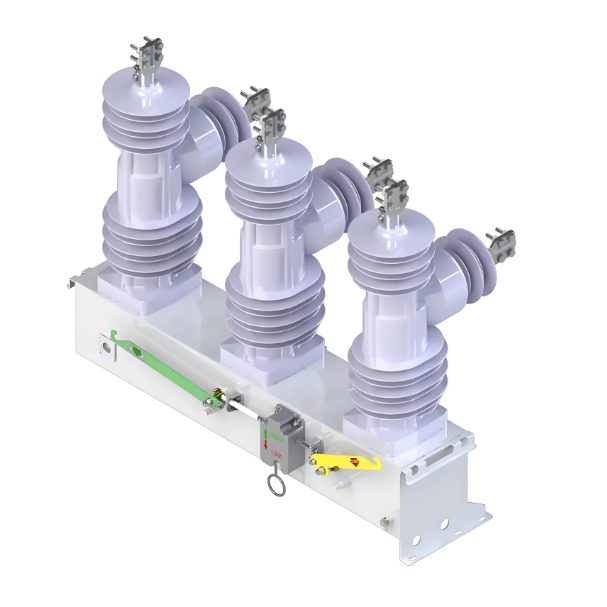

Product show:

What are the key points for the selection of outdoor vacuum reclosers?

System Parameter Matching: Choose a recloser that matches the rated voltage, rated current, and short-circuit current levels of the power system. Ensure that the rated voltage of the recloser is equal to or higher than the system voltage, the rated current meets the requirements of the line load current, and the rated short-circuit breaking and making currents are greater than the maximum possible short-circuit current in the system.

Reclosing Performance Requirements: Consider the specific requirements of the power system for the reclosing function, such as the number of reclosures, reclosing time intervals, and reclosing success rate. Based on different application scenarios and power supply reliability requirements, select a recloser with appropriate reclosing performance. For example, for critical power supply lines, a recloser with a higher number of reclosures and flexible reclosing time intervals may be required.

Type of Operating Mechanism: Choose an appropriate operating mechanism based on actual needs. Spring-operated mechanisms are suitable for outdoor environments where high reliability is required and maintenance conditions are relatively poor. Permanent magnet-operated mechanisms are better suited for applications requiring high action speed and frequent operations.

Environmental Adaptability: Given the harsh conditions of outdoor environments, consider the environmental adaptability of the recloser. This includes weather resistance, pollution resistance, and water and dustproof performance. Selecting a recloser with good environmental adaptability ensures stable performance during long-term outdoor operation.

Brand and Quality: Choose well-known brands and high-quality recloser products. These products have strict quality control systems in design, manufacturing, and testing, ensuring the performance and reliability of the product. Additionally, good after-sales service is an important factor to consider when choosing a brand, as it ensures timely resolution of issues that may arise during equipment operation.