Specialized Voltage Transformer Solution for High-Speed Railway AT Power Supply System: Focused on Strong EMI Immunity

Specialized Voltage Transformer Solution for High-Speed Railway AT Power Supply System: Focused on Strong EMI Immunity

The electromagnetic environment of the high-speed railway AT (Auto-Transformer) power supply system is extremely complex. Strong electromagnetic interference (EMI) directly affects the measurement accuracy of voltage transformers and system reliability. This solution specifically targets this core challenge by developing a dedicated voltage transformer that meets the 27.5kV single-phase power supply standard, providing a solid foundation for energy metering and relay protection on high-speed railways.

Core Technological Breakthrough: Triple Defense Against EMI Storms

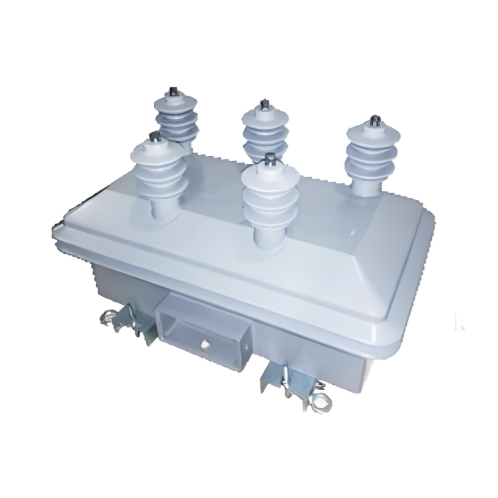

- μ-Metal Alloy Triple Electromagnetic Shield:

- Structure: Utilizes three independent inner, middle, and outer shielding shells constructed from high-permeability μ-metal alloy.

- Efficacy: Effectively absorbs/blocks low-frequency strong magnetic field interference generated by the 27.5kV overhead contact line and high-frequency transient EMI caused by system switching operations. The core sensing element is effectively shielded, ensuring signal purity.

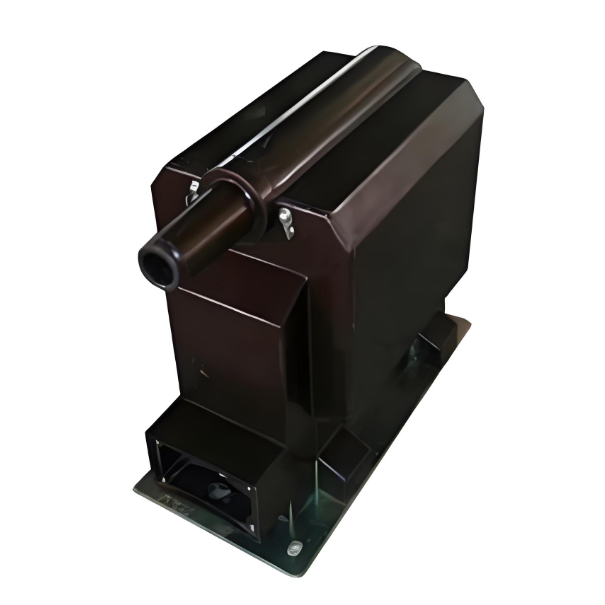

- 27.5kV Dedicated Single-Phase Structural Design:

- Precise Matching: Magnetic circuit and windings are deeply optimized for the 27.5kV power-frequency single-phase characteristics, eliminating phase-to-phase crosstalk effects and enhancing absolute accuracy of single-point measurement.

- Stability: Special materials and processes significantly reduce core saturation risk, guaranteeing transient response speed and waveform reproduction capability.

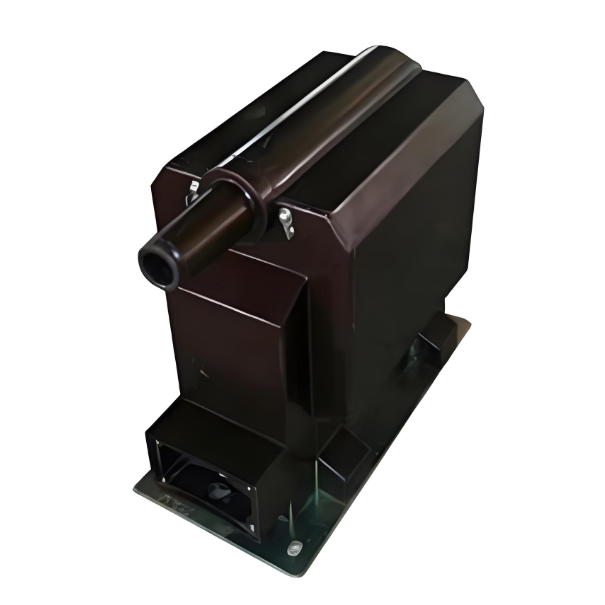

- Vibration Resistance Enhancement (5-200Hz, 2g Acceleration):

- Simulation-Driven: Utilizes FEA (Finite Element Analysis) to simulate complex vibration spectra at trackside locations (including characteristic vibrations induced by passing CRH trains).

- Reinforcement Solution: Internal core components are secured using elastic silicone potting. The external housing employs high-strength alloy and anti-vibration structural elements, ensuring zero connection loosening/displacement under long-term mechanical impact for consistent accuracy.

- CRH Standard Communication Interfaces (RJ45 + TNC):

- Dual Assurance: The RJ45 interface provides standardized digital communication based on mature Ethernet physical layer. The redundantly designed TNC interface (coaxial connector) ensures highly reliable transmission of critical analog/digital signals under extreme interference.

- Immunity Capability: Interface circuits feature built-in multi-layer EMC protection (TVS, filtering). Ports comply with the rigorous IEC 61000-4 series standards for surge and EFT immunity.

Key Performance Indicators: Hardware Commitment to Accuracy & Reliability

|

Parameter |

Performance Indicator |

Test Standard / Notes |

|

Rated Voltage |

27.5kV / √3V (Phase Voltage) |

- |

|

Accuracy Class |

0.2S |

Complies with GB/T 20840.1 / IEC 61869-1 |

|

Temperature Drift |

≤ ±0.002%/K |

Stability throughout full operating range (-40℃ ~ +70℃) |

|

Electrical Fast Transient (EFT) |

4kV (Peak) |

Meets IEC 61000-4-4 Level 4 |

|

Power Frequency Withstand |

Per GB/T 20840 / IEC standards |

- |

|

Partial Discharge |

≤ 10pC @ 1.2 Ur |

IEC 60270 |

Environmental Resilience: The Robust Guardian at Trackside

- Protection Class: IP65 - Comprehensive protection against dust ingress and high-pressure water jets, impervious to rain, snow, wind, and sand.

- Operating Temperature: -40℃ ~ +70℃ - Wide-temperature materials and special processes selected to withstand extreme seasonal climate challenges across all regions of China, ensuring consistent performance.

- Installation: Designed for trackside pole or compact substation environments, featuring a compact structure for easy installation and maintenance.