Photovoltaic Transformer Solution for Middle Eastern Environments: Resilience Under the Desert Sun

06/28/2025

Photovoltaic Transformer Solution for Middle Eastern Environments: Resilience Under the Desert Sun

Executive Summary:

The Middle East presents immense solar potential but also unique challenges for PV plant transformers. This solution delivers robust, high-efficiency transformers specifically engineered to withstand extreme heat, sand, humidity, and grid conditions prevalent in the region, maximizing uptime and ROI for solar projects.

Core Challenges in the Middle East:

- Extreme Ambient Temperatures: Consistently exceeding 45°C, requiring significant derating of standard units.

- Abrasive Sand & Dust: Penetration causes insulation damage, cooling obstruction, and component wear.

- Coastal Corrosion: High salinity and humidity attack materials and electrical connections.

- Thermal Cycling: Significant day/night temperature swings induce material stress.

- Grid Instability: Voltage fluctuations and harmonic distortion necessitate resilient designs.

- Remote Locations: Demands exceptional reliability and ease of maintenance.

Our Tailored PV Transformer Solution:

- Enhanced Thermal Resilience & Capacity:

- High-Temperature Insulation: Utilizes Nomex, TUF/FORTREX, or high-grade cellulose with H-class (180°C) thermal capability, providing ample thermal headroom.

- Lower Hot Spot Rise Design: Specifies significantly lower Temperature Rise guarantees (e.g., 55K or 60K) compared to standard units (65K), ensuring safety margins at peak ambient heat.

- Amplified Cooling: Oversized radiators, high-capacity fans (IP56 rated), and potential for directed airflow systems for forced cooling during peak heat.

- Accurate Derating: Calculations based on actual site ambient temperature + solar irradiance heat gain, not just standardized ratings.

- Superior Environmental Protection:

- Extreme Sealing (IP56/IP65): Prevents ingress of fine sand and dust into the tank and cooling ducts. Hermetically sealed options available.

- Anti-Corrosion Protection:

- Tank: Hot-dip galvanized steel with heavy-duty epoxy/polyurethane painting (C5-M classification).

- Components: Stainless steel fittings, corrosion-resistant hardware.

- Enclosure (For Dry-Type): IP65 rated stainless steel or coated aluminum enclosures.

- Protected Cooling System: Sand shields on radiators, easily accessible external cleaning ports, IP56-rated fans with sealed bearings.

- Optimized for PV & Local Grid:

- Wide Input Voltage Range: Accommodates voltage fluctuations common in regional grids (e.g., ±10%, custom ranges available).

- Harmonic Handling (k-Rating / THD): Designed with low-loss cores & appropriate conductor sizing to handle harmonics generated by inverters.

- Efficiency Focus: Utilizes high-quality GOES or amorphous core materials with low no-load loss designs (e.g., meeting EU Tier 2/Tier 3 or DOE 2016 levels), maximizing energy yield over lifetime.

- Lightning Impulse Withstand: Enhanced insulation coordination and BIL levels suited to regional lightning activity.

- High Availability & Low Maintenance:

- Robust Design Philosophy: Over-dimensioned critical components, conservative thermal margins.

- 30-35% Overload Capacity: Crucial for managing production surges post-sandstorm clearing or during short-duration peak irradiance.

- Advanced Monitoring Compatibility: Built-in features for thermal probes (OT/PT100), Buchholz relay, DGA sampling valve (for oil units), pressure monitoring, compatible with SCADA integration for remote health assessment – reducing need for site visits.

- Liquid Options: High-performance mineral oil remains cost-effective for extreme heat. Synthetic ester fluid available for enhanced fire safety (Liq. K class), biodegradability, and superior moisture handling.

Configuration Scenarios:

- Central Inverter Architecture:

- Transformer: 480V (LV Inverter) / 34.5kV (MV Collection) step-up units.

- Key Features: IP56 liquid-filled or IP65 dry-type, enhanced cooling (fans), max kVA rating derated for ambient, high corrosion protection.

- String Inverter Architecture:

- Transformer: Larger pad-mounted units (e.g., 3000kVA+) stepping from 33kV to 132kV or 220kV for grid interconnection.

- Key Features: OFWF cooling for highest capacity/heat dissipation, heavy-duty IP56 protection, advanced monitoring (DGA, Winding Temp), significant overload capacity, corrosion resistance.

- Containerized PV Solutions:

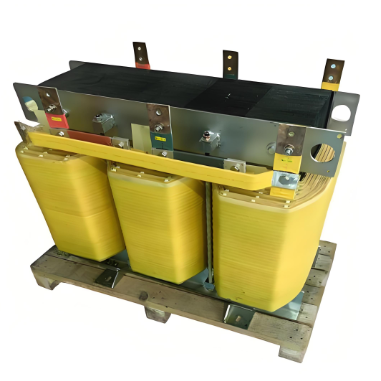

- Transformer: Compact dry-type transformers (VPI resin cast) within climate-controlled inverter skids.

- Key Features: Focus on compactness, ventilation coordination within the skid, IP65 rating.

Certification & Compliance:

- International Standards: IEC 60076, IEEE C57.12.xx

- Regional Standards: SASO, ESMA (UAE), GCC Conformity Marking Scheme requirements.

- Specific Certifications: IEC TS 60076-22-11 (Transformers for Solar Applications), applicable fire safety standards.

Value Proposition for Middle East Projects:

- Maximized Uptime & ROI: Reduced failure rates directly translate to higher energy production and revenue.

- Extended Lifespan: Robust construction withstands harsh environments beyond the 25-year project life.

- Reduced O&M Costs: Sealed design, protected cooling, and remote monitoring minimize cleaning and inspection needs in remote areas.

- Operational Flexibility: Built-in overload capacity handles extreme conditions and production peaks.

- Compliance & Peace of Mind: Adherence to regional and international standards ensures grid acceptance and safety.