| Brand | POWERTECH |

| Model NO. | Rack type energy storage battery |

| Energy storage capacity | 2.56kWh |

| Cell quality | Class A |

| Series | Industrial&Commercial energy storage |

Peculiarity:

High energy density.

Equipped with BMS battery management system, longer cycle life.

Beautiful appearance; Standard rack specifications, free combination, easy installation.

The panel integrates a variety of interfaces, supports multiple protocols, and ADAPTS to most photovoltaic inverters and energy storage converters.

Can be customized adjustment management battery charging and discharging strategy.

Modular design, easy maintenance.

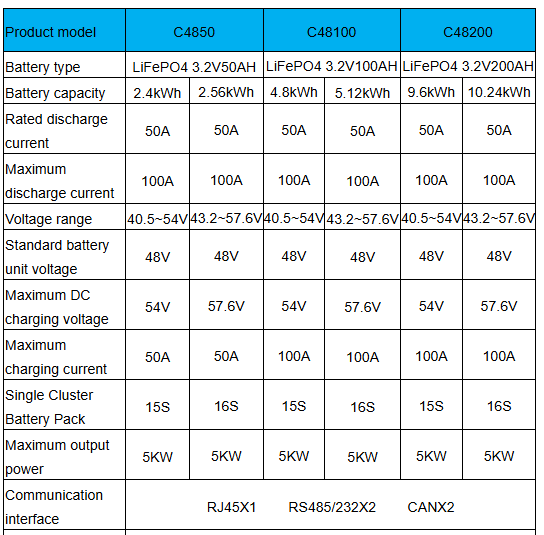

Technical parameter:

Note:

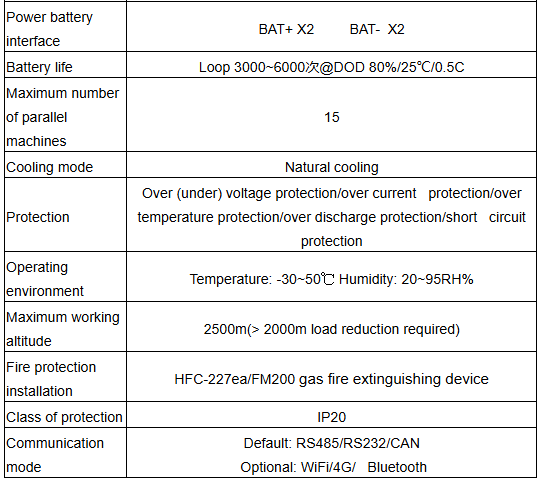

The A-class cell can charge and discharge 6000 times, and the B-class cell can charge and discharge 3000 times, and the default discharge ratio is 0.5C.

Class A cell warranty 60 months, Class B cell warranty 30 months.

What are the characteristics of rack-mounted energy storage batteries?

High integration:All components (such as battery modules, battery management system (BMS), inverter, energy management system (EMS), etc.) are integrated in one or more standard racks, which is convenient for transportation and on-site installation.The racks usually follow certain standard sizes, such as the standard server cabinet with a width of 19 inches.

Modular design:The rack-mounted energy storage battery allows users to add or remove specific modules as needed to expand or reduce the capacity of the energy storage system.The energy storage units in each rack can operate independently or be combined into a larger energy storage system in parallel or in series.

Standardized interfaces:The rack-mounted design usually adopts standardized interfaces, making components of different brands or models interchangeable or compatible, reducing the difficulty of system integration.

Easy installation and maintenance:The rack-mounted design makes the installation of the energy storage system very simple. Only the rack needs to be placed in an appropriate position and necessary electrical connections are made.During maintenance, each module can be easily accessed for inspection or replacement.

High space utilization:The design of standard racks can maximize space utilization, enabling the energy storage system to achieve a high energy storage density in a limited space.

Remote monitoring and management:The rack-mounted energy storage system usually integrates remote monitoring and management functions, and the system can be monitored and controlled in real time through the Internet or a dedicated network.This characteristic is very important for energy storage applications that require remote operation and maintenance.

Environmental adaptability:The rack-mounted design can integrate environmental conditioning equipment such as temperature control and humidity control to ensure that the battery operates under optimal working conditions.The rack itself can also be designed with characteristics such as dustproof and waterproof to improve the environmental adaptability of the system.