| Brand | RW Energy |

| Model NO. | 215kW Intelligent energy storage liquid-cooled integrated cabinet(Industrial and commercial energy storage) |

| Rated frequency | 50/60Hz |

| Battery Capacity | 418kWh |

| Rated power | 215kW |

| Series | M-L |

Product Overview

The 215kW Intelligent Energy Storage Liquid-Cooled Integrated Cabinet is specifically designed for commercial and industrial scenarios. It uses liquid-cooling temperature control technology to precisely regulate temperature (temperature difference ≤3℃), ensuring stable cell operation. Equipped with an intelligent battery management and monitoring system, it flexibly enables peak-valley price arbitrage and efficient consumption of excess photovoltaic power. The three-level fire protection system builds a solid safety defense, while the flexible AC/DC configuration adapts to different power demands. The lightweight single-unit design facilitates rapid deployment and installation, providing commercial and industrial users with a safe, reliable, intelligent, and efficient full-scenario energy storage solution.

Key Features

Flexible and efficient

AC and DC can be designed independently to achieve flexible configuration

No parallel circulation, significantly reducing energy loss

Small weight of the single unit and easy installation

Safe and stable

Equipped with three-level fire protection systemto achieve all-round protection of the system

Precise liquid-cooled temperature control design to achieve long-term stability, the temperature difference of different cells is ≤3°C

Balanced battery management to prolong battery life

Intelligent collaboration

Intelligent switching strategy for different scenarios: peak shaving and valley filling, capacity management, dynamic capacity increase, new energy consumption, plan curve response

Local and cloud monitoring linkage, digital rapid diagnosis, intelligent automatic inspection

3S synergy, EMS closed-loop safety logic, to achieve system security

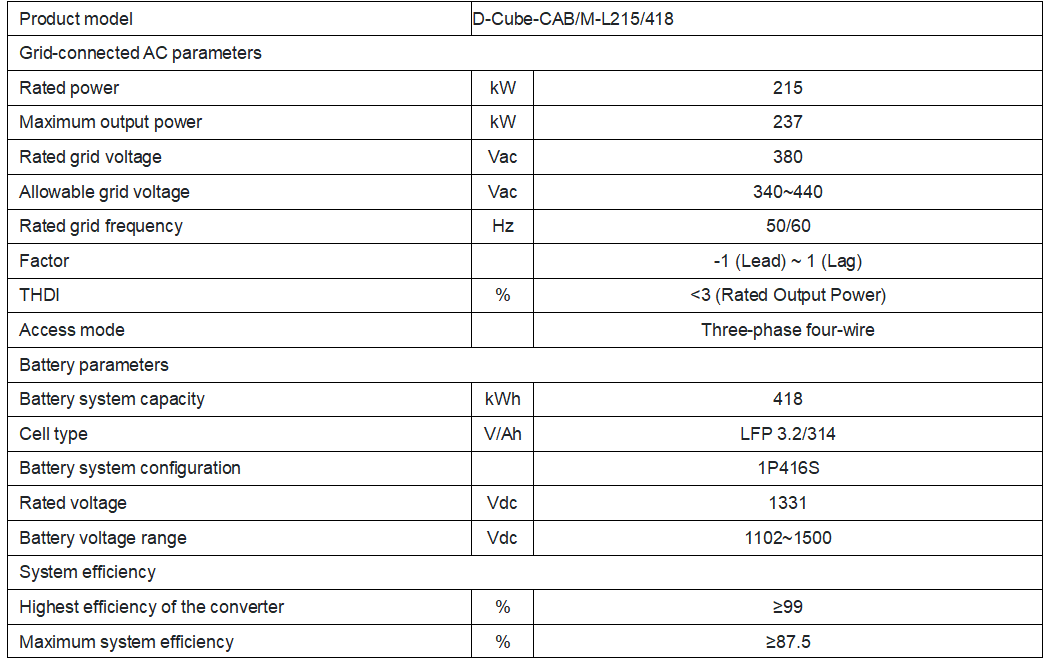

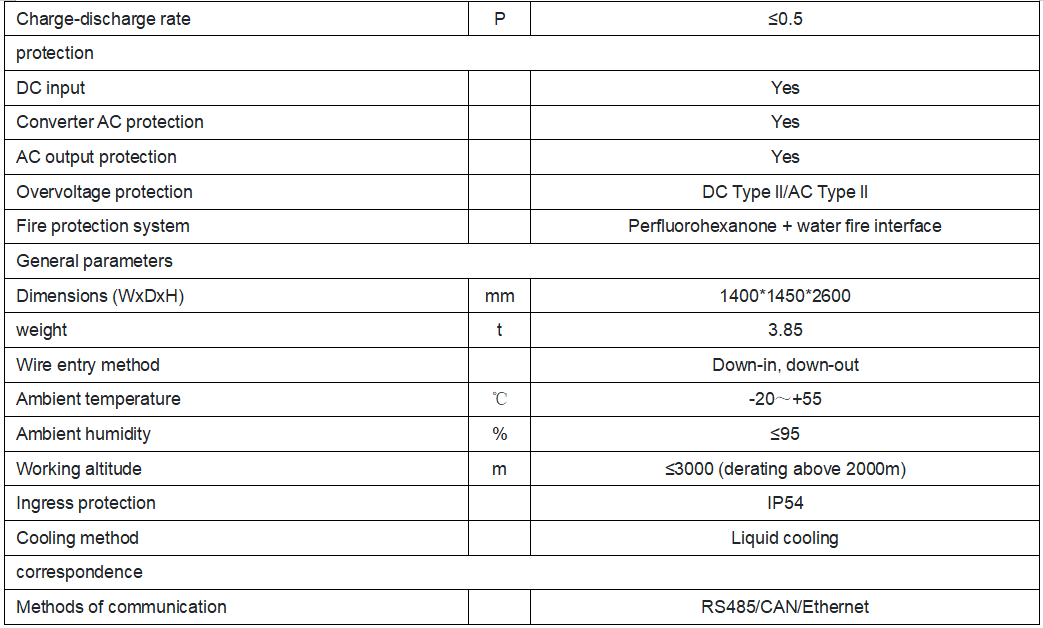

Technical Parameter