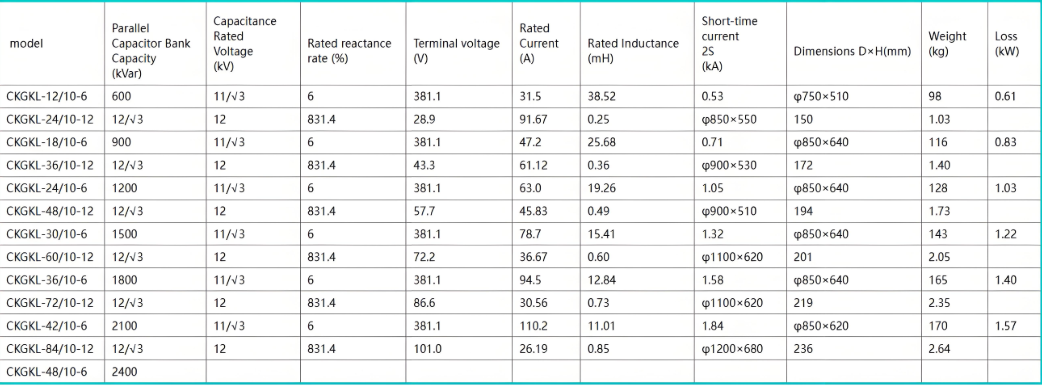

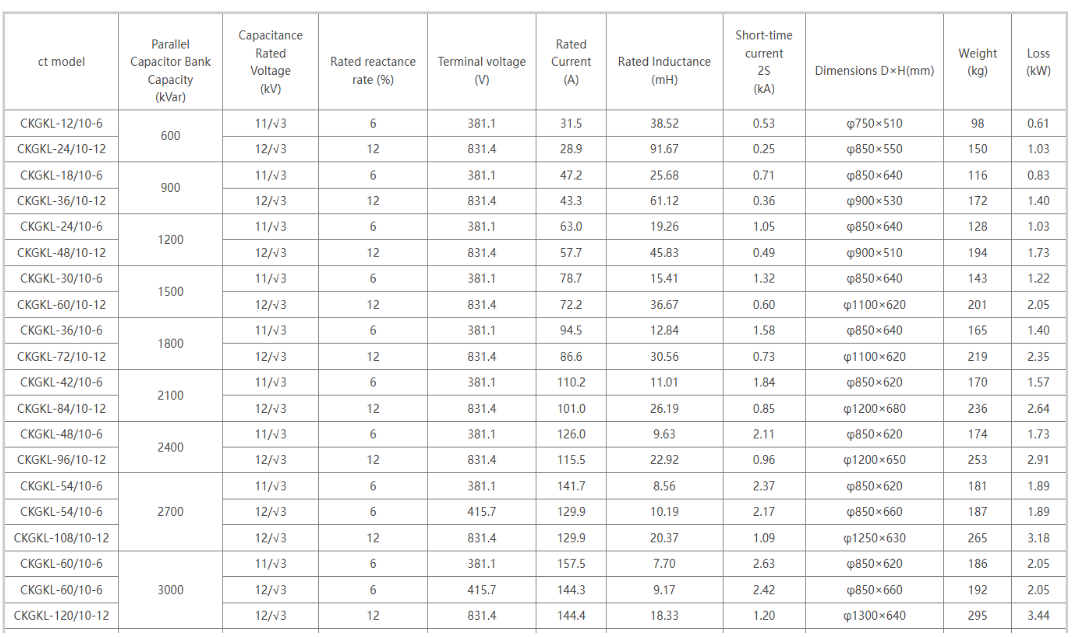

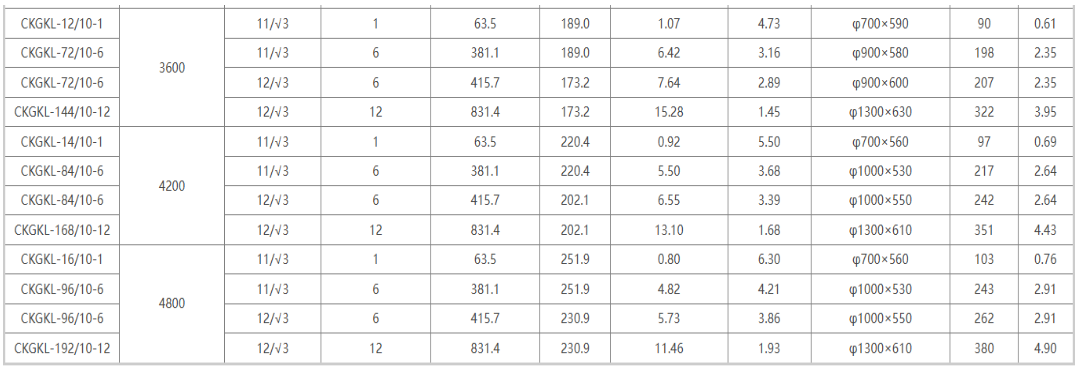

| Brand | Wone |

| Model NO. | High-voltage dry air-core reactors |

| Rated voltage | 12kV |

| Capacity | |

| Series | CKGKL |

Product use:

The series reactor is an important supporting equipment for the reactive power compensation device of the power system. After the series reactor is connected in series with the shunt capacitor bank, it can effectively suppress the higher harmonics in the power grid and limit the mergingThe gate inrush current and operating overvoltage improve the voltage waveform of the system and improve the power factor of the power grid, which plays a great role in the safe operation of power capacitors and other power equipment. Widely involveElectric power, automobile, shipbuilding, metallurgy, chemical industry, machinery manufacturing, papermaking, coal, communications, airports, electroplating, large venues, high-rise buildings and other places and industries.

Ordering parameters:

System rated voltage and frequency;

Rated capacity and terminal voltage of supporting capacitor bank;

Rated reactance or reactance rate of reactor;

Reactor installation method;

The angle between the inlet and outlet lines of the reactor;

Other special requirements.

Parameters to be provided when ordering

Insulation level: LI75AC42,

What are the common faults and handling methods of high-voltage dry-type air-core reactors?

Surface Tree-like Discharge and Turn-to-Turn Short Circuit:

After operating outdoors for some time, dirt and contaminants can accumulate on the surface, and the insulating material can degrade, forming a layer of contamination. When this layer becomes damp, the surface leakage current increases, generating heat that evaporates the moisture and creates dry spots. This leads to changes in local surface resistance, which can cause arcing and develop into tree-like discharge marks. A turn-to-turn short circuit is a further development of this issue.

Remedial Measures:

Proper selection of insulating materials.

Improvement of manufacturing processes and quality.

Ensuring the integrity of end insulation and encapsulation.

Application of hydrophobic coatings.

Embedding ring-shaped equalizing electrodes at the ends.

Installation of rain shields and additional protective layers.

Increasing the frequency of cleaning the reactor and insulator surfaces in heavily polluted areas.

Temperature Rise Impact:

During normal operation, high currents can cause significant temperature rise, which accelerates the aging of insulating materials, leading to a loss of insulation properties and a shortened equipment lifespan. In severe cases, it can result in burnout accidents.

Causes:

Poor welding quality due to production process limitations.

Limited design margins for temperature rise due to cost constraints during the design phase.

External operating conditions that impede air circulation and make heat dissipation difficult.

Remedial Measures:

Improving welding quality.

Selecting insulating materials with appropriate thermal resistance.

Regularly shutting down the equipment for maintenance and cleaning to remove any accumulated dirt or debris.