| Brand | ROCKWILL |

| Model NO. | 1KVA-3000KVA Photovoltaic Isolation Transformer |

| Rated frequency | 50/60Hz |

| Rated capacity | 1650kVA |

| Phases | Three-phase |

| Series | SG |

Product Overview:

For many years, our company has specialized in producing SD/SG (YSD) series single - phase and three - phase dry - type transformers for mechanical equipment with capacities ranging from 1KVA to 3000KVA, using high - quality materials and advanced process technology. The products are newly developed with reference to similar products of Siemens. The SG series three - phase dry - type transformers not only have a voltage transformation function in the power grid, but also can isolate the third - harmonic of the power grid from the equipment, reducing the heat generation of the machine and the reduction of the service life of insulation materials. It is especially suitable for imported equipment (380V input → 220V output, 380V input → any voltage output, 220V input → any voltage output) with specifications ranging from 1KVA to 3000KVA. The SG and DG series dry - type isolation transformers are widely applicable to various power supply occasions with AC 50 - 60HZ, input and output voltages not exceeding 3000V. Various inputs, outputs, voltage levels, connection groups, adjustment tap positions, winding capacity distribution, secondary winding configuration, and whether a housing is required, etc., are all carefully designed and manufactured according to user requirements.

Key Features:

Wide Capacity: 1KVA-3000KVA range suits residential to large-scale industrial PV systems.

Electrical Isolation: Separates PV from grid, blocks interference, safeguards equipment & personnel from voltage spikes.

High Efficiency: Advanced materials and design reduce power loss for optimized PV system energy conversion.

Reliable Build: Premium silicon steel and insulation ensure excellent heat dissipation, enduring harsh conditions for long-term use.

Customizable: Tailors input/output voltages, connections, and specs to fit unique project needs for seamless PV integration.

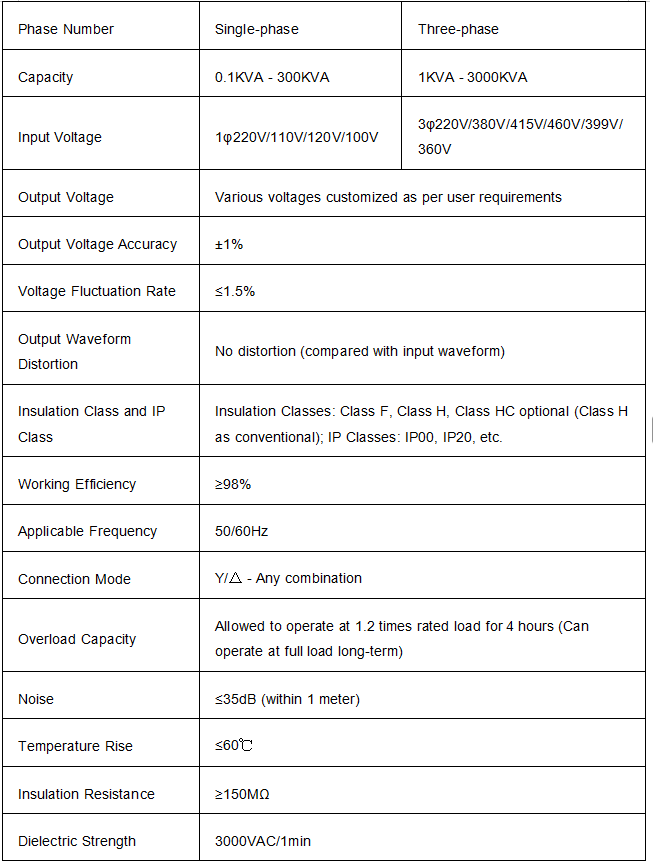

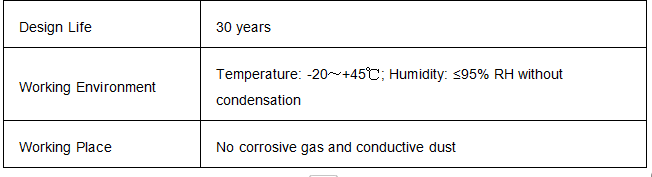

Technical data:

Product Operating Conditions:

Applicable altitude: ≤ 5000m

Ambient temperature: -15℃ ~ +45℃

Relative humidity: ≤ 90%

The installation site shall be free from gases, vapors, chemical deposits, dirt, conductive dust that seriously affect the insulation strength of the transformer, and from other explosive, flammable, and corrosive substances.