DIN Rail Single Phase ModBUS protocol Smart Energy Meter Manufacturer

$90.00

Model

| Brand | Wone |

| Model NO. | DIN Rail Single Phase ModBUS protocol Smart Energy Meter Manufacturer |

| Rated voltage | 230V |

| Rated normal current | 0.25-5(45)A |

| Series | D119001-02 |

Description

DIN RAILstandard installation size,only 36.5mm width;

It can be up to 80A;

Double row display,upper row is forcurrent energy,the below row is fortotal energy;

LCD display with blue backlight, which is better for data reading in dark or low light conditions;

Meter has reset function. Press "RESET"button formore than 10s, the upper row data (current energy) will be reset

Specifications

| Main |

|

|---|---|

| Range | D119001-02 |

| Product or Componet Type | Smart Energy Meter |

| Country of origin | China |

| Complementary |

|

|---|---|

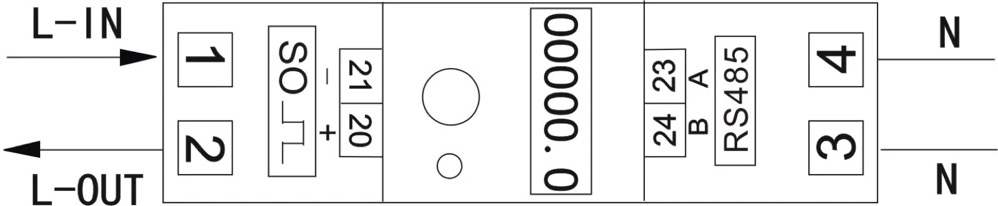

| Phase | Single Phase |

| Type of measurement | 1-total =forward 2-Total=reverse 3-Total =forward +reverse (default) 4-Total=Forward-Reverse |

| Metering type | Measurement |

| Device Application | Solar Power Energy Charge |

| Accuracy class | Active power 1.0 |

| Rated Current | 0,5-5(30)A,0,5-5(32)A,0,5-5(40)A,0,5-5(45)A, 0,5-5(50)A,0,5-5(60)A, 0,5-5(80)A |

| Rated Voltage | 230V |

| Network Frequency | 50-60Hz |

| Technology Type | Electronic |

| Display Type | LCD display(LCD5+1) |

| Impulse Constant | 1000imp/kWh(LED) |

| Maximum value measured | 99999.99kWh |

| Tariff input | ----------- |

| Communication port protocol | Modbus |

| Communication port support | RS485 |

| Local signalling | ------ |

| Number of inputs | ------- |

| Number of Outputs | -------------- |

| Output voltage | 230V |

| Mounting Mode | Clip-on |

| Mounting Support | DIN rail |

| Connections - terminals | ------- |

| Standards | IEC62052-11 IEC62053-21 IEC62053-31 |

| Environment |

|

|---|---|

| IP degree of protection | IP51 indoor |

| Relative humidity | 5…95 % 97 °F (36 °C) |

| Ambient air temperature for operation | -40…70 °C |

| Ambient Air Temperature for Storage | --40…70 °C |

| Operating altitude | 4000 m |

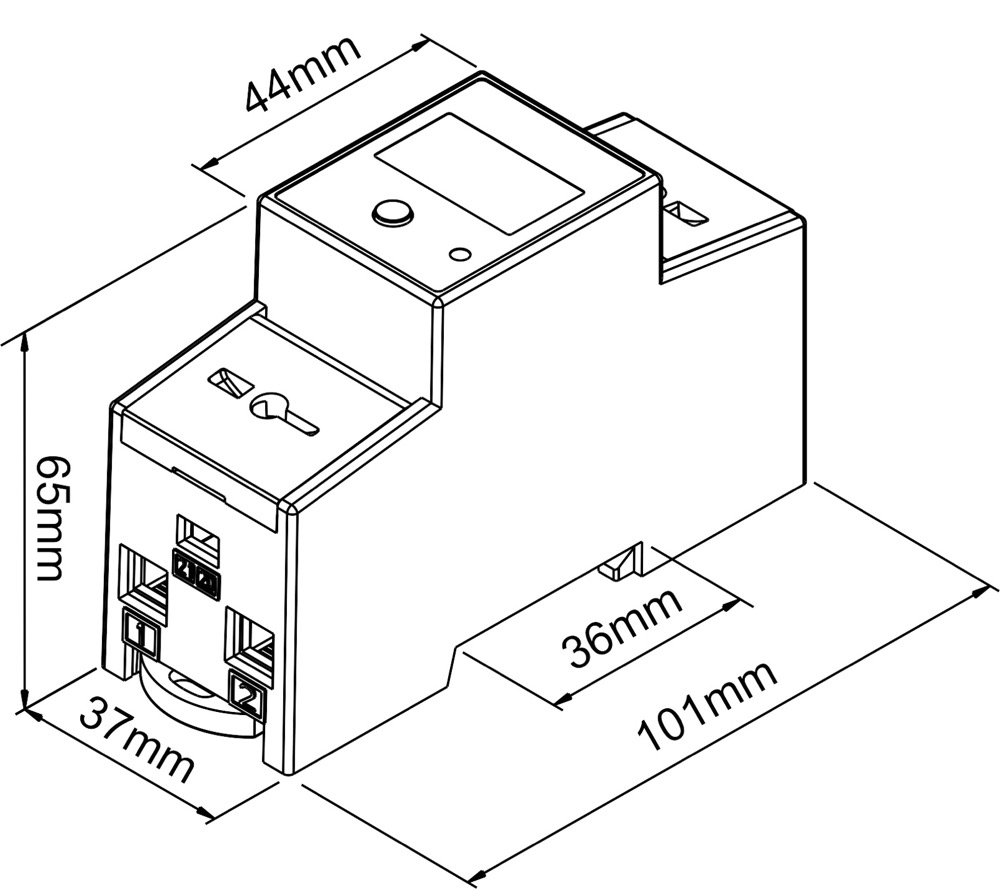

| Dimensions | 110mm*37mm*65mm |

| Packing Units |

|

|---|---|

| Unit Type of Package 1 | PCE |

| Number of Units in Package 1 | 1 |

| Package 1 Height | 65mm |

| Package 1 Width | 37mm |

| Package 1 Length | 110mm |

| Package 1 Weight | 1.000kg |

Dimensions