| Brand | Wone |

| Model NO. | Box integrated ESS |

| Cooling mode | Forced air cooling |

| Rated Output Rating | 50KW |

| Energy storage capacity | 107kWh |

| Series | Industrial&Commercial energy storage |

Peculiarity:

Modular energy storage converter parallel design concept, improve system stability, easy installation and maintenance, easy expansion.

Battery pack is replaceable, can be adapted to a variety of batteries, for different batteries to achieve different charging and discharging strategies; Low operation and maintenance cost.

Energy scheduling can be regulated, and users can change the charge and discharge logic according to the power consumption policy of different periods in the region.

Power factor can be adjustable, can achieve active power, reactive power independent control, to meet the needs of different loads.

Energy balance management controller is used to refine the energy management of the energy storage system to the battery PACK level.

Battery PACK level energy balance management controller to avoid capacity loss caused by mismatch.

Support the mix of old and new batteries, so that recharge phased deployment.

Outdoor modular energy storage converter cabinet design, high power density, easy maintenance.

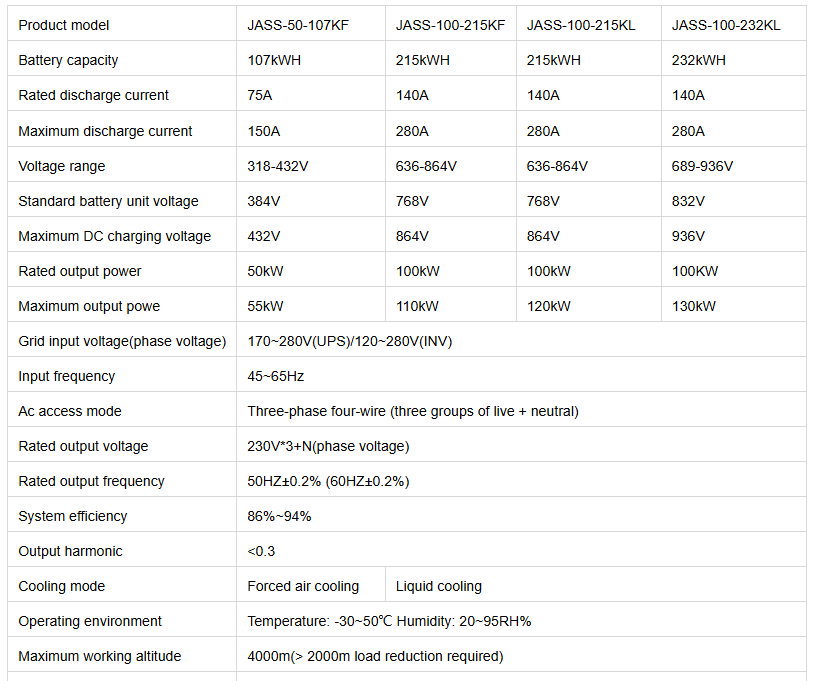

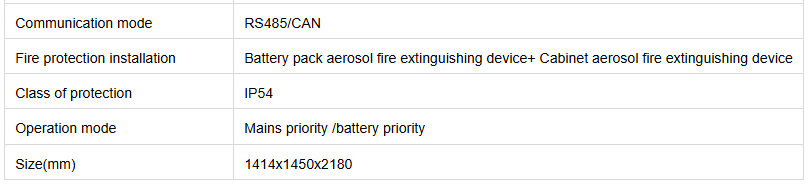

Technical parameter:

How does the battery management system in ESS protect against short circuits?

Identify short-circuit situations.

Current detection:The BMS identifies short-circuit conditions by continuously monitoring the current changes of the battery pack. When an abnormally high current is detected, a short circuit may have occurred.

Voltage monitoring:In the case of a short circuit, the voltage of the affected battery cell or the entire battery pack may suddenly drop. The BMS identifies this abnormal situation through vltage monitoring.

Temperature monitoring:A short circuit will cause a sharp rise in local temperature. The BMS detects abnormal temperature rises through temperature sensors to determine whether a short circuit has occurred.

Implement protection measures.

Cut off power supply:When a short circuit is detected, the BMS will immediately cut off the connection between the battery pack and the external circuit through relays or switches to prevent the current from continuing to flow and avoid excessive discharge or heating of the battery.

Alarm and record:Trigger the alarm system to send a warning signal to the operator and record relevant information such as the time and location of the short circuit occurrence for subsequent investigation and handling.

Isolate faulty units:If the short circuit occurs in a certain battery cell rather than the entire battery pack, the BMS can isolate the cell to prevent it from affecting other normal battery cells.