| Brand | Wone |

| Model NO. | 580-605Watt MONO-FACIAL MODULE |

| Maximum Power | 600Wp |

| Series | 72HL4-(V) |

Certification

IEC61215:2021 / IEC61730:2023 ·

IEC61701 / IEC62716 / IEC60068 / IEC62804 ·

ISO9001:2015: Quality Management System ·

ISO14001:2015: Environment Management System ·

ISO45001:2018: Occupational health and safety management systems.

Features

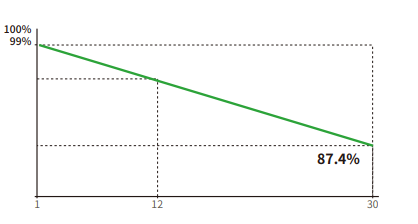

N-type modules with Tunnel Oxide Passivating Contacts (TOPcon) technology offer lower LID/LeTID degradation and better low light performance.

N-type modules with JinkoSolar's HOT 3.0 technology offer better reliability and efficiency.

High salt mist and ammonia resistance.

Certified to withstand: 5400 Pa front side max static test load 2400 Pa rear side max static test load.

Better light trapping and current collection to improve module power output and reliability.

Minimizes the chance of degradation caused by PID phenomena through optimization of cell production technology and material control.

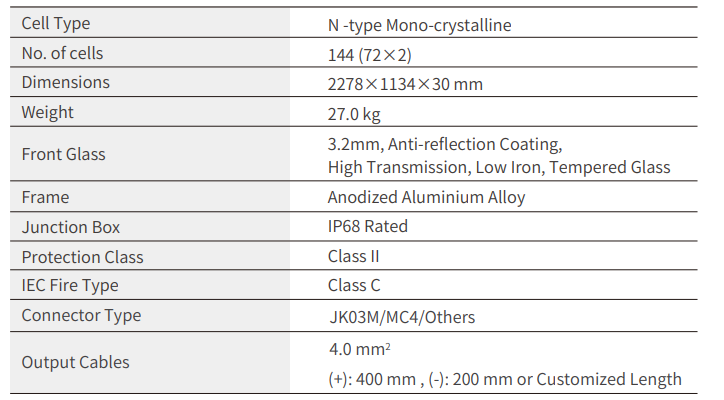

Mechanical Characteristics

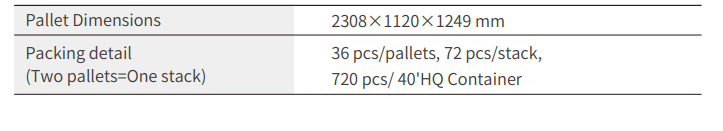

Packaging Configuration

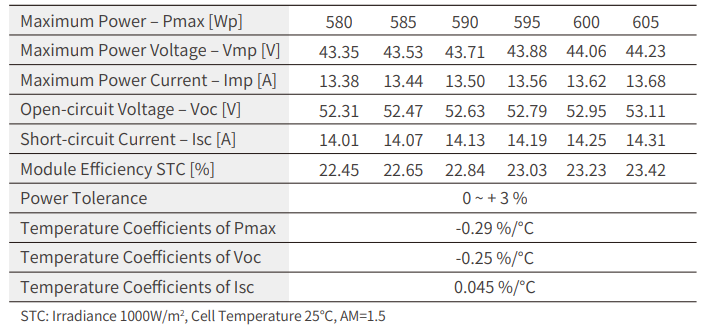

Specifications (STC)

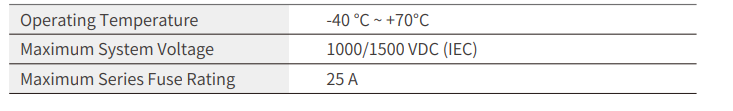

Application Conditions

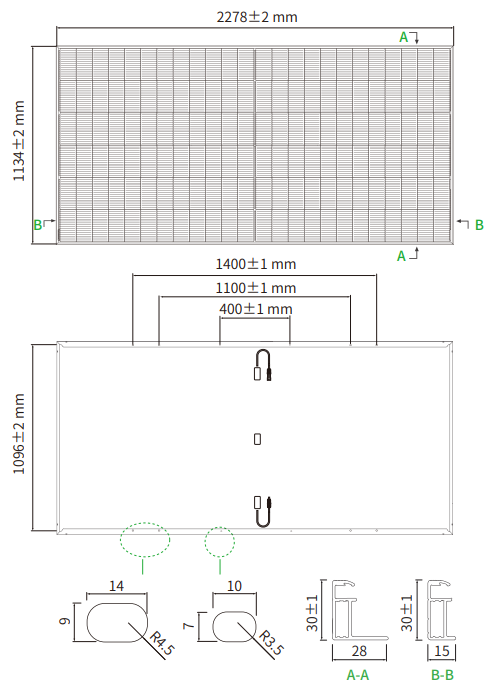

Engineering Drawings

*Note: For specific dimensions and tolerance ranges, please refer to the corresponding detailed module drawings.

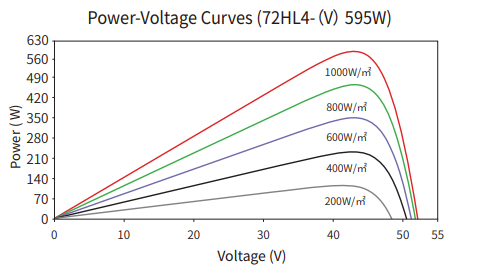

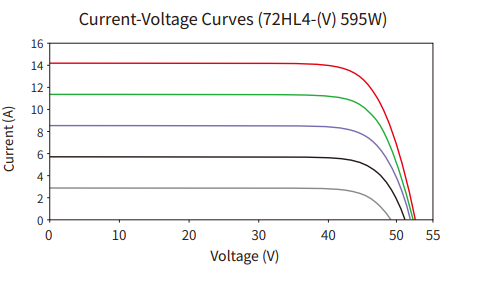

Electrical Performance

What is TOPCon technology?

TOPCon technology (Tunnel Oxide Passivated Contact) is an advanced photovoltaic cell technology used to enhance the efficiency of solar cells in converting sunlight into electricity. The essence of TOPCon technology is the introduction of a tunneling oxide layer and a doped polysilicon layer on the rear side of the cell, which forms a passivated contact structure. This structure reduces surface recombination and metal contact recombination, thereby improving the performance of the cell.

Tunnel Oxide Layer: An ultra-thin tunneling oxide layer is fabricated on the back side of the cell. This layer is thin enough to allow electrons to tunnel through but thick enough to reduce surface recombination losses.

Doped Polysilicon Layer: A layer of doped polysilicon is deposited on top of the tunneling oxide layer. This layer can be either N-type or P-type doped and is used to collect charge carriers.

Passivated Contact: The passivated contact structure, formed by the tunneling oxide layer and the doped polysilicon layer, effectively reduces surface recombination and metal contact recombination, thereby increasing the cell's open-circuit voltage and short-circuit current.