| Brand | ROCKWILL |

| Model NO. | 12kV Indoor High Voltage Vacuum Circuit Breaker |

| Rated voltage | 12kV |

| Rated normal current | 3150A |

| Series | VDS4 |

The VDS4 series indoor high-voltage AC vacuum circuit breaker is designed for three-phase AC 50Hz power systems with a rated voltage ranging from 7.2 to 40.5kV. Widely applied in substations, power plants, industrial facilities, airports, and buildings, it excels at controlling and safeguarding electrical equipment. With its capabilities for frequent operations and rapid reclosing, it ensures reliable power management.

This breaker adheres to national standards, including GB/T 1984-2014 "High Voltage AC Circuit Breaker", JB/T 3855-2008 "High Voltage AC Vacuum Circuit Breaker", and DL/T 403-2000 "12kV~40.5kV Indoor AC High Voltage Vacuum Circuit Breaker Ordering Technical Requirements". It also complies with international regulations set by the International Electrotechnical Commission, such as IEC 62271-100, IEC 60694, and IEC 62271-1, guaranteeing quality and global compatibility.

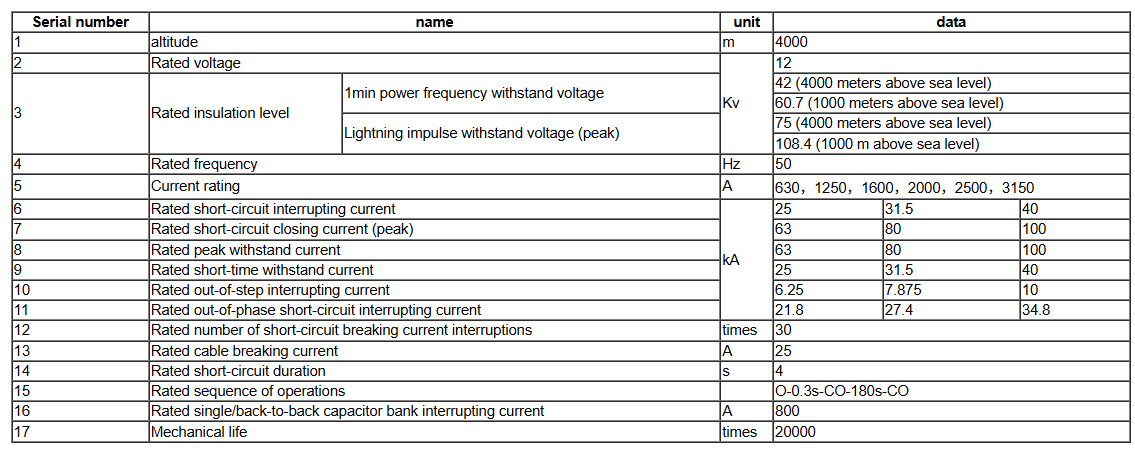

The following table details the key technical specifications of the product, comprehensively covering electrical performance, mechanical characteristics, and dimensional parameters to provide a clear reference for technical selection and application scenarios.

Features

The product offers multiple significant advantages, which can fully meet the diverse needs of industrial and power systems. Specifically included are:

Excellent Electrical Performance of Fully Enclosed Pole

The main circuit of the VSV series vacuum circuit breaker adopts a fully enclosed structure, available in two types: insulated cylinder or solid pole.

Insulated Cylinder Structure:

The main electrical components are longitudinally installed in an epoxy resin cylinder cast via the APG process. This structure offers superior arc resistance, anti-aging properties, and high mechanical strength. It effectively shields the vacuum interrupter from external factors such as mechanical impacts and environmental pollution while enhancing the conductive circuit’s capability to withstand rated short-term (peak) withstand currents.

Sealed Pole Structure (P Series):

The miniaturized vacuum interrupter and other main circuit components are directly sealed in epoxy resin using advanced APG technology. This not only simplifies the pole assembly process and improves the reliability of the vacuum interrupter’s conductive circuit but also protects the interrupter’s outdoor surface from external mechanical forces and environmental influences.

Corrosion-Resistant Mechanism with Advanced Design

Structural components undergo super anti-corrosion and anti-salt spray zinc-nickel alloy treatment.

Transmission parts are treated with high-hardness, wear-resistant, and corrosion-resistant nickel-phosphorus alloy.

International brand INA oil-free graphite bearings are used for transmission, ensuring high strength and excellent wear resistance.

C2-Level Circuit Breaker Compliance

During capacitive current interruption, the breaker exhibits an extremely low probability of re-strike, fully meeting the requirements for C2-level circuit breakers.

E2-Level Circuit Breaker Certification

The breaker has successfully passed all tests at the Shenyang High Voltage Electrical Appliance Research Institute and Xi’an High Voltage Electrical Appliance Research Institute testing centers. It complies with the E2-level standard, demonstrating:

30 operations with full-rated short-circuit current for low-current breakers.

20 operations with full-rated short-circuit current for high-current breakers.