| Brand | Wone |

| Model NO. | PAUWAY-SME series alternators |

| Prime power | 1200KW |

| Reserve power | 1320KW |

| Series | SME |

Description:

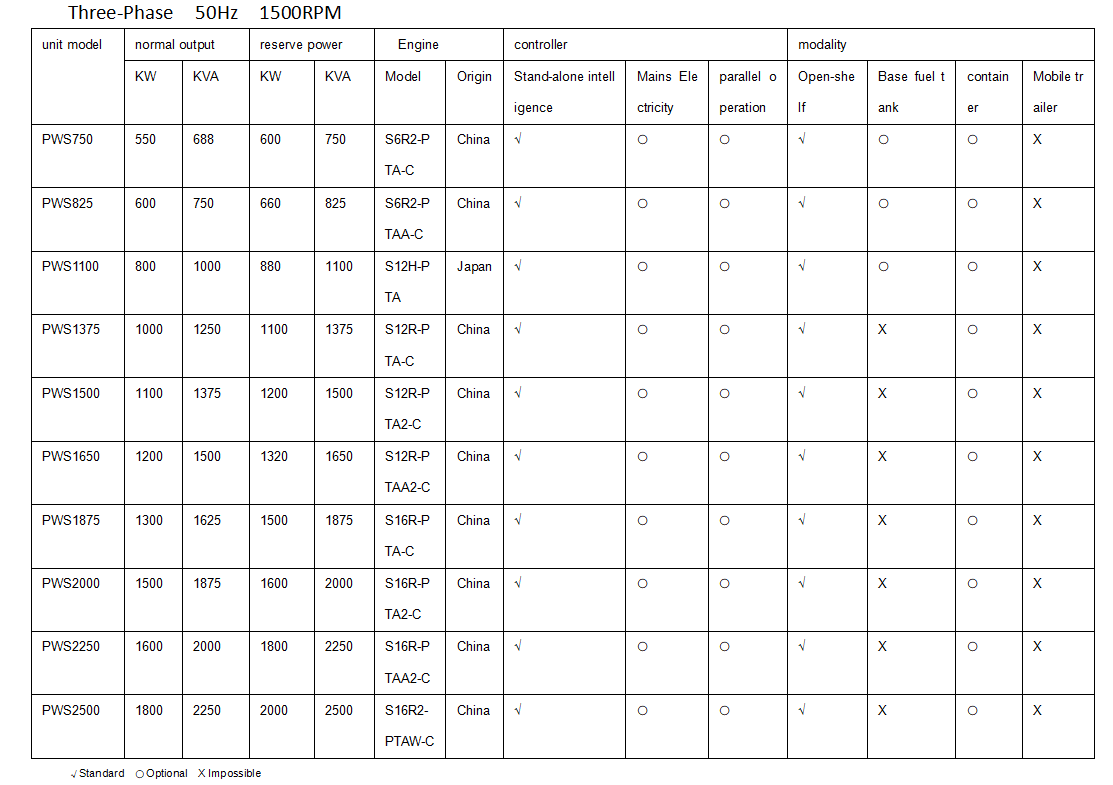

Diesel generator set type spectrum.

The PWS Series - uses SME brand engines from a joint venture between China and Mitsubishi, with the option of Stamford, Marathon or Leroy-Somer alternators.

Voltage optional: 380V/400V/415V/480V/6.3kV/10.5kV (special voltage can be customized).

Technical parameters:

Remark:

All ratings are for reference only, please refer to the specific generator set technical data sheet for final power ratings.

All rating data are based on ISO 8528-1, 1SO 3046, DIN6271 operating under conditions using typical fan sizes and gear ratios. PAUWAY quotes a performance tolerance of ±5%.

Prime power = power under available load instead of the main grid. 10% overload is allowed for one hour of operation every 12 hours.

Standby power = power available under variable load in the event of a failure in the main grid, up to 500 hours per year. Overload is not allowed.

Rated power factor: 0.80.

N/A: Not available.

We reserves the right to change models, technical specifications, colors, configurations and accessories without prior notice. Please contact our sales team before ordering.

What is Fuel Injection Technology?

Taking the electronic control gasoline injection system as an example, the electric fuel pump is installed inside the fuel tank. It draws fuel from the tank and pressurizes it. The pressurized fuel then passes through a fuel filter to remove impurities before being delivered to the distributor pipe located above the engine. The distributor pipe connects to injectors mounted on the intake manifold of each cylinder.

The injector is essentially an electromagnetic valve controlled by the computer (Electronic Control Unit, ECU). Based on signals from sensors such as the air flow sensor and crankshaft position sensor, the ECU calculates the engine's air intake volume and speed, determining the basic fuel injection quantity accordingly. It further adjusts the fuel injection quantity based on operating parameters like throttle opening, engine coolant temperature, and intake air temperature. The ECU controls the duration of each fuel injection cycle to regulate the amount of fuel injected, ensuring that the fuel is sprayed in a fine mist into the intake manifold where it mixes with air and is drawn into the cylinders during the intake stroke.

Precise Fuel Injection Control: By accurately controlling the fuel injection quantity, it ensures complete combustion of fuel, reducing waste and lowering fuel consumption.

Optimized Fuel Injection for Various Conditions: The system can promptly adjust the fuel injection quantity and timing according to different engine conditions (e.g., idle, acceleration, high-speed driving), optimizing the air-fuel mixture concentration. This improves the engine's output power and torque, enhancing acceleration performance.

Complete Combustion: Precise fuel injection control promotes more thorough combustion, reducing emissions of harmful gases such as carbon monoxide, hydrocarbons, and nitrogen oxides, thus meeting increasingly stringent environmental standards.