| Brand | Vziman |

| Model NO. | 33-38kV Dry-type Distribution Transformer 800KVA/1000KVA/1250KVA/1500KVA |

| Rated voltage | 33-38kV |

| Rated capacity | 800kVA |

| Series | SC (B) 10 |

Descripton:

SC (B) 10 epoxy resin cast dry-type transformer is manufactured according to standard of Dry-type Power Transformer, characterized with low performance loss, good energy saving effect, economic operation and no maintenance. In addition to high process structure metal, short-circuit resistance and lightning impulse level, it is still characterized with flame retardant, damp-proof, dust-proof and low noise, which can be connected to load center. It is widely used in high-rise buildings, airport, station, wharf, power plant, transformer substation, etc., especially applicable to be used in places with high fire protection requirements for flammable and combustible materials.

Parameter:

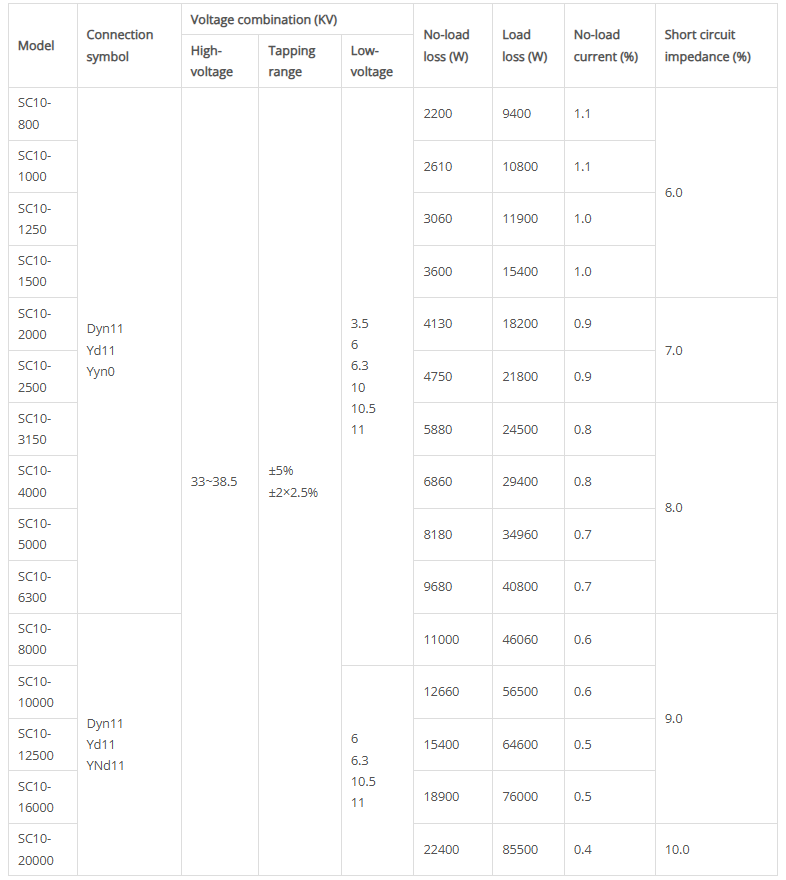

See the table for main performance parameters of SC (B) 10.

Number of phases: 3-phase.

Frequency: 50Hz.

Insulation endurance class: Class F.

Average temperature rise of winding: ≤100K.

Magnitude of partial discharge: <5pc.

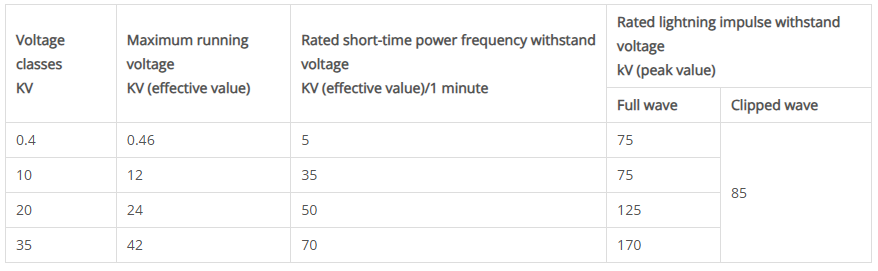

Insulation level:

How to maintain and maintain dry-type distribution transformers?

Maintenance and Care:

Regular Inspection: Regularly inspect the operating status of the transformer, including its temperature, sound, and appearance.

Cleaning: Keep the surrounding environment of the transformer clean to prevent dust and debris from entering the interior of the transformer.

Ventilation: Ensure sufficient ventilation for the transformer to avoid overheating.

Load Monitoring: Monitor the load condition of the transformer to avoid running it under overload for a long period.

Insulation Testing: Regularly test the insulation performance of the transformer to ensure safe operation.