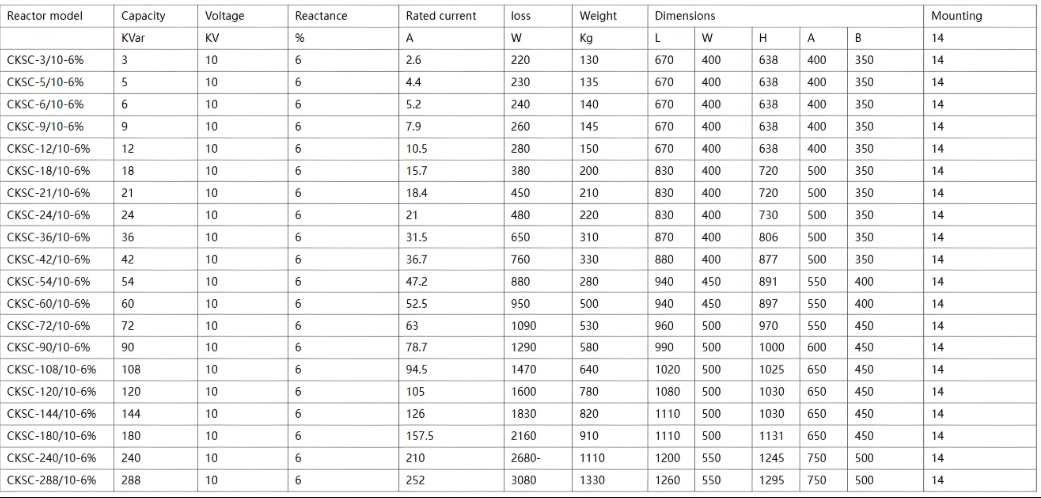

| Brand | Wone |

| Model NO. | High-voltage series reactors |

| Rated voltage | 10kV |

| Capacity | 6KVar |

| Series | CKSC |

Function:

The series reactor is connected in series with the shunt capacitor group, which has the functions of compensating the reactive power of the power grid, improving the power factor, suppressing the harmonic current, limiting the closing inrush current, etc., and is suitable for the power system, electrified railway, metallurgy, petrochemical and other high fire protection requirements. Places such as urban grid substations, underground substations and microcomputer-controlled substations with limited electromagnetic interference requirements and installation space.

Parameters to be provided when ordering:

The rated capacity of the reactor.

System rated voltage and frequency.

Capacitor terminal voltage.

Rated reactance or reactance rate of reactor.

Rated current and continuous current.

Dynamic and thermal stability current and duration.

Other special requirements.

Standard:

IEC289-88 "reactor".

GB10229-88 "Reactor".

JB5346-98 "Reactor".

DL462-92 "Technical Conditions for Ordering Series Reactors for High Voltage Shunt Capacitors".

Structural characteristics:

The reactor is divided into three phase and single phase, both of which are epoxy casting.

The core is made of low-loss cold-rolled oriented silicon steel sheet, which is punched and sheared by a high-speed punch, which has small burrs, regular uniformity, and neat and beautiful lamination, so as to ensure the performance of low temperature rise and low noise during the operation of the reactor.

The coil is epoxy casting, the coil is reinforced by laying epoxy glass mesh cloth inside and outside, and the F-class epoxy casting system is used to pour in a vacuum state, the coil not only has good insulation performance, but also has good mechanical strength, and can withstand large current impact and cold and hot shock without cracking.

The epoxy casting coil does not absorb water, has low partial discharge, and can operate safely under harsh environmental conditions.

The upper and lower ends of the coil are made of epoxy cushion blocks and silicone rubber shockproof pads, which effectively reduce the vibration of the coil during operation.

Conditions for the use:

The altitude does not exceed 2000 meters.

The operating environment temperature is -25°C~+40°C, and the relative humidity is not more than 93%.

There are no harmful gases around, no flammable and explosive materials.

The surrounding environment should have good ventilation conditions.

Insulation Grade: Class F, Reactor Noise: ≤45dB

Overload capacity: continuous operation at ≤ 1.35 times

The uneven transverse between the phases of the reactor is not more than ±3%, and the inductance error is controlled within +3%.

Insulation level: LI75AC35kV

What is the principle of inductance characteristics of a reactor?

Inductive Characteristics Principle:

Reactors operate based on the principle of electromagnetic induction. When current flows through the windings, a magnetic field is generated in the core. According to Lenz's Law, this magnetic field opposes the change in current, thereby limiting the rate of change of the current.

For example, in an alternating current (AC) circuit, where the current is continuously changing, the inductance of the reactor causes the current to lag behind the voltage in phase. This phase shift results in the generation of reactive power, which can be used for reactive power compensation in the circuit.

In a direct current (DC) circuit, reactors can smooth out the current, reducing fluctuations and providing a more stable current flow.