The Design of Substation Relay Protection Fault Information Detection System

Oliver Watts

04/28/2025 16:21:28

I. Introduction

In recent years, with the continuous expansion of the power grid scale, substations, as crucial nodes in the power system, play a vital role in ensuring the reliability of the entire power grid through their safe and stable operation. Relay protection serves as the first line of defense for the safe operation of substations. The accuracy and rapidity of relay protection are directly related to the stability of the power system. Therefore, effectively detecting the fault information of the substation relay protection system, promptly identifying and addressing potential faults, are of great significance for safeguarding the safe operation of the power system.

Traditional methods for detecting relay protection faults mainly rely on manual inspections and regular maintenance. These methods are not only time-consuming and labor-intensive but also unable to achieve real-time monitoring. As a result, they are prone to missing the early signals of faults. With the continuous development of information technology, especially the advancements in computer technology and communication technology, modern substation relay protection fault information detection systems have started to adopt automated methods. Through real-time data collection, these systems can achieve real-time monitoring of the relay protection status and quickly locate faults.

Therefore, this paper proposes a substation relay protection fault information detection system based on modern information technology and elaborates in detail on its hardware structure, software design, and experimental results.

II. Design of the System Hardware Structure

(1) Host Computer

(1) Host Computer

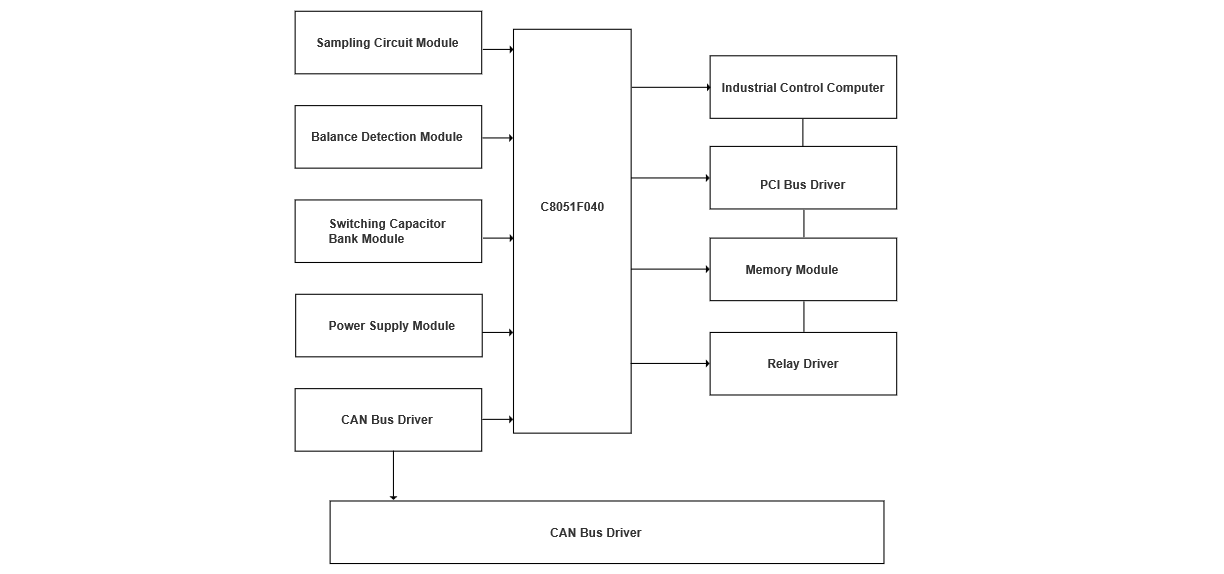

The design of the host computer directly affects the performance of the entire system. Its hardware structure uses the C8051F040 single-chip microcomputer as the core processor. The C8051F040 single-chip microcomputer is a high-performance and low-power mixed-signal microcontroller that integrates abundant peripheral resources, including analog and digital I/O ports, timer/counters, UART, SPI, and I2C communication interfaces, among others. These characteristics make the C8051F040 highly suitable as the core processor of the host computer, capable of meeting the requirements of high-speed data processing and complex control logic.

To ensure the real-time monitoring capability of the system, a high-performance monitoring unit is employed in the design of the host computer. This unit typically includes a high-speed ADC (Analog-to-Digital Converter), DAC (Digital-to-Analog Converter), as well as voltage/current monitoring circuits. It can collect and convert electrical parameters in real-time, providing accurate data support for fault diagnosis.

Meanwhile, the host computer needs to communicate with the lower computer and the remote monitoring center. The design incorporates various communication interfaces, such as RS-232, RS-485, and Ethernet. These interfaces ensure the rapid transmission of data and the ability of remote control.

To facilitate operators in monitoring and controlling the system, the host computer is also equipped with a human-machine interaction interface, usually consisting of an LCD display screen and a keyboard. Operators can use these interfaces to view the system status in real-time.

(2) Insulation Detection Sensor

To meet the renovation requirements of the DC systems in old power plants and substations, the staff has designed a high-precision detachable insulation detection sensor. Adopting advanced electronic technologies and materials, this sensor features high sensitivity, high stability, and a long service life, and it can operate stably even in harsh environments.

High precision is a key performance indicator of the insulation detection sensor. By using advanced detection algorithms and electronic components, it can accurately detect minute insulation changes, ensuring the accuracy and timeliness of fault information.

By upgrading and renovating the thermal insulation devices of the DC systems in old power plants and substations and employing high-precision detachable insulation detection sensors, the safety of the system can be significantly enhanced. These sensors have the capability of high-precision detection and can promptly detect insulation faults, thereby effectively preventing the occurrence of accidents .

(3) Early Warning Detection Module

To improve the accuracy and response speed of early warnings, this module generally integrates a dual mechanism of active early warning and passive early warning.

Active early warning refers to the system's proactive detection of electrical parameters. Once the parameters deviate from the normal range, an early warning signal will be immediately triggered. Active early warning usually relies on high-performance sensors and data collection devices. These devices can monitor key parameters such as current, voltage, and frequency in real-time and analyze the relevant data through built-in algorithms to determine whether there are potential fault risks.Passive early warning, on the other hand, involves analyzing relevant electrical parameters and issuing an early warning signal after the system receives external signals. For example, when the relay protection device in the substation operates, the passive early warning module will be activated immediately to analyze the cause of the operation and determine whether further processing measures are required, as shown in Figure 1.

Figure 1 Hardware Structure Design

In the hardware structure design of the early - warning detection module, combining active early - warning and passive early - warning can significantly enhance the system's early - warning ability and response speed. Active early - warning can monitor electrical parameters in real - time and quickly identify potential fault risks; while passive early - warning can react promptly when specific events occur and conduct in - depth analysis of the fault causes.

To effectively combine these two early - warning methods, the following key elements need to be considered in the hardware design:

- Selection of sensors and data collection devices: High - precision sensors and data collection devices must be selected to ensure data accuracy.

- Data processing and analysis capabilities: The early - warning monitoring module should have powerful data processing and analysis capabilities to quickly identify abnormal data and make early - warning judgments.

- Communication interfaces and protocols: The module should support multiple communication interfaces and protocols to facilitate data exchange with other systems or devices.

- Reliability: The hardware design should ensure that the module can operate stably in extreme environments and adopt necessary safety measures to prevent misoperation and unauthorized access .

III. System Software Design

(1) Simulation Modeling of Fault Load Characteristics

(1) Simulation Modeling of Fault Load Characteristics

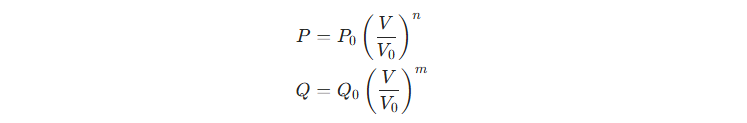

The core of the substation relay protection fault information detection system lies in its software structure design, especially the construction of static and dynamic load models. These models aim to describe the active and reactive power of the load during system operation, as well as the slow changes in voltage and frequency, and are usually expressed using polynomial models. The static load model is usually expressed as:

where P and Q represent active and reactive power respectively, V is the voltage, P0, Q0, V0are the values in the reference state, and n and m are the load characteristic coefficients.

The dynamic load model is relatively complex. It takes into account the dynamic response of the load to changes in voltage and frequency, including multiple time constants to simulate the response speed of the load to voltage and frequency changes. The dynamic load model can be expressed as a series of differential equations that describe the rate of change of load power over time.

In the software structure design, these models are integrated into the relay protection fault information detection system to monitor and analyze the operation status of the substation in real - time. The system collects real - time data, including current, voltage, power, etc., and uses these models for calculations to scientifically identify potential fault conditions .

(2) Fault Information Collection

To ensure the reliability of relay protection equipment, the design of the fault information detection system is of particular importance, especially the part of fault information collection. This part is usually divided into three modules: steady - state information collection, transient information collection, and status file management.

The steady - state information collection module is mainly responsible for collecting the electrical parameters of the substation during normal operation, such as voltage, current, power, etc. These data are the basis for evaluating the operation status of the power grid and also important for fault analysis and prediction. This module usually includes three sub - modules: data collection, data processing, and data storage [4]. The data collection sub - module obtains electrical parameters in real - time through the interface with the substation monitoring system; the data processing sub - module conducts preliminary analysis on the collected data, removes abnormal values, and formats the data; the data storage sub - module stores the processed data in a database for subsequent analysis.

The transient information collection module focuses on capturing transient events in the power grid, such as short - circuits, open - circuits, and other faults. These transient events are often accompanied by sharp changes in electrical parameters, so high - speed and high - precision data collection equipment is required. This module usually includes three sub - modules: high - speed data collection, transient event identification, and event data storage. The high - speed data collection sub - module can record the changes of electrical parameters with a microsecond - level resolution; the transient event identification sub - module judges whether a fault has occurred and accurately identifies the fault type according to preset algorithms; the event data storage sub - module stores the identified fault information in a specific database, which is conducive to in - depth analysis by the staff.

The status file management module is responsible for the management and maintenance of the status files of the substation relay protection equipment, and it records key information such as the configuration details, operation status, and historical fault records of the protection equipment in detail. It mainly includes four sub - modules: status file generation, update, query, and backup. The generation sub - module generates an initial status file according to the actual configuration of the protection equipment; the update sub - module updates the status file when the equipment parameters or configuration change; the query sub - module allows users to query the information in the status file; the backup sub - module regularly backs up the status file to effectively avoid data loss.

(3) Fault Information Detection

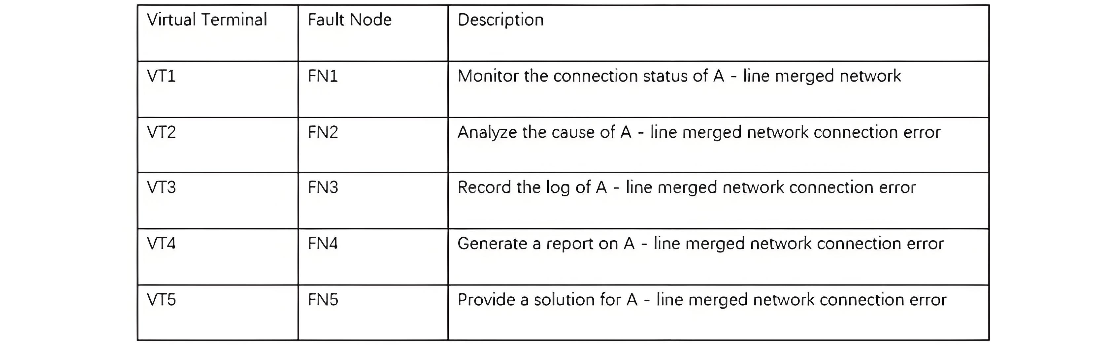

When the station control layer receives the alarm information "A - line merged network connection error" from the relay protection, the system should immediately start the fault information detection process to confirm whether this alarm is the sole source, that is, whether other devices have also issued similar alarms . In this example, if other devices do not issue alarms, the system will focus on the information of "A - line merged network connection error".

To process and analyze fault information more effectively, the system designs five combinations of virtual terminals and fault nodes, as shown in Table 1.

Table 1 Detection Data

Each virtual terminal is responsible for different tasks, from monitoring the network connection status to providing solutions, forming a complete fault handling process. Through the above software structure design, the substation relay protection fault information detection system can effectively detect fault information and ensure the safe operation of the substation. Especially when receiving the alarm of "A - line merged network connection error", the system can respond quickly and take corresponding measures to minimize the impact of the fault on the power system .

IV. Experimental Verification

(1) Network Topology Structure

(1) Network Topology Structure

The network topology structure design of the relay protection fault information detection system for the 500 kV substation put into operation in 2023 strictly adheres to the core principles of high reliability, high availability, and easy maintenance. This system adopts a hierarchical and distributed network architecture, and its implementation steps are well - organized, mainly including the following links.

- Data collection: Through sensors and data collection devices installed at various key nodes of the substation, the operation data of the relay protection devices are collected in real - time.

- Data transmission: Using network communication technology, the collected data are transmitted to the data processing center in a timely and accurate manner.

- Data analysis: In the data processing center, high - performance computers and professional analysis software are used to analyze the data, identify abnormal patterns and potential faults.

- Fault diagnosis: Once an abnormality is detected, the system automatically conducts fault diagnosis to determine the type and location of the fault.

- Alarm and response: The system notifies the operation and maintenance personnel of the fault information through the alarm system and provides preliminary fault handling suggestions.

- Fault handling: The operation and maintenance personnel can quickly take measures to handle the fault according to the fault information and suggestions provided by the system, thus ensuring the stable operation of the power grid.

(2) Experimental Results and Analysis

Two detection systems were used in the experiment: one is the conventional substation relay protection secondary circuit on - line detection system based on the SCD file, and the other is the substation relay protection fault information detection system based on spatio - temporal analysis. Both systems were tested in the same substation environment to ensure the comparability of the results [8].

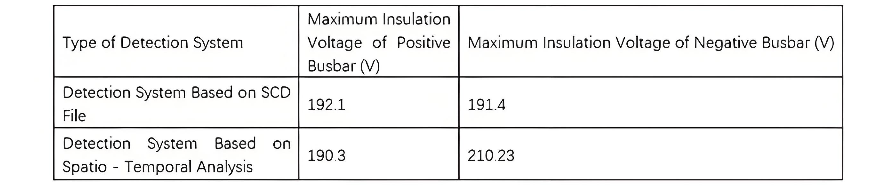

The experimental data show that the maximum insulation voltages of the positive and negative busbars measured by the detection system based on the SCD file are 192.1 V and 191.4 V respectively, while the corresponding values measured by the detection system based on spatio - temporal analysis are 190.3 V and 210.23 V respectively. The specific data are shown in Table 2.

Table 2 Test Data

From the experimental results, it can be seen that the detection system based on spatio - temporal analysis has a slightly lower maximum insulation voltage value for the positive busbar compared to the detection system based on the SCD file, but a slightly higher value for the negative busbar. This indicates that the detection system based on spatio - temporal analysis can provide more accurate measurement results in certain situations. However, this difference is not significant. Therefore, to gain a more in - depth understanding of the performance differences between these two systems, it may be necessary to further collect and analyze a large amount of experimental data.

V. Conclusion

The new substation relay protection fault information detection system designed and studied in this paper can monitor the working status of relay protection devices in real - time, automatically analyze and diagnose fault information, and promptly transmit the fault information to operation and maintenance personnel through network communication technology. This enables them to take prompt measures to prevent the expansion of faults and ensure the safe and stable operation of the power system.

Hey! I'm Oliver Watts, an electrical engineer in Inspection and Testing. With years of hands - on experience, I ensure electrical systems meet top safety and performance standards. Using advanced gear, I conduct diverse tests, easily spotting issues in both large - scale industrial and small - scale commercial setups. I love teaming up, sharing knowledge, and keeping up with industry regs. Also, I'm skilled at data analysis with software. If you're into electrical inspection or just want to chat engineering, reach out. Let's connect and explore!