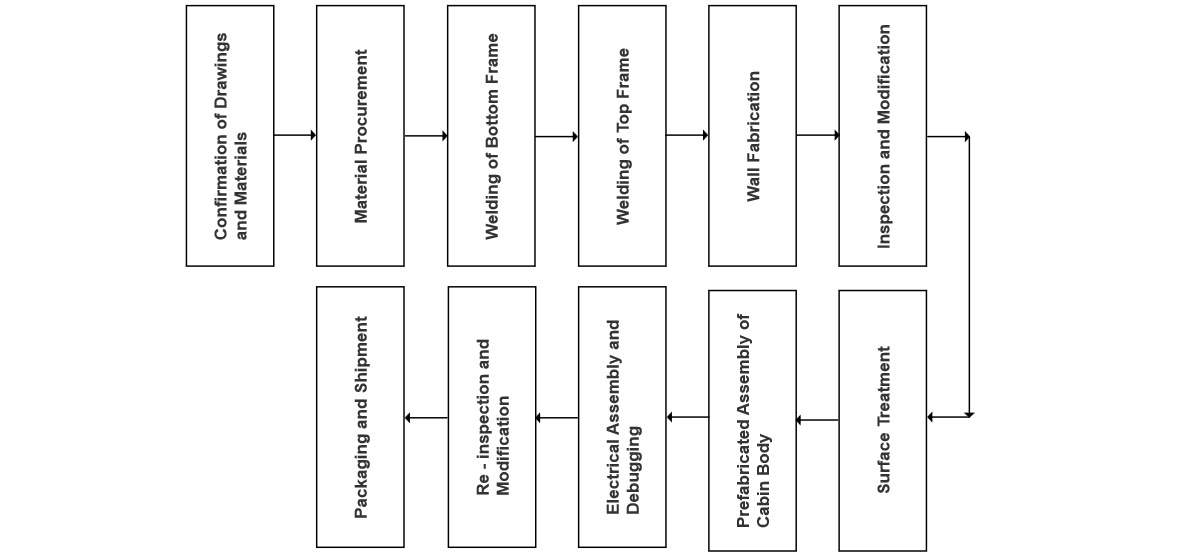

Design and Process Technology of Prefabricated Cabin - type Substations

Dyson

04/28/2025

CAE simulation technology is adopted to conduct simulation and analysis of the prefabricated cabin structure under conditions such as hoisting, wind load, snow load, and earthquake, to verify the reliability of the cabin structure, reduce design costs, shorten the design cycle, and improve product reliability.

- Hoisting Condition Simulation: CAE simulation technology is used to analyze the stress and deformation of the prefabricated cabin module under gravitational load during hoisting. The lifting points are located at the four lifting lug mounting holes on the bottom channel steel of a single module.

Focused on the design of electrical equipment, proficient in electrical principles and relevant specifications, and skilled in using design software. From intelligent substations to various types of electrical equipment, I am adept at optimizing design solutions, integrating new technologies. With practical experience and collaborative management capabilities, I deliver outstanding electrical design achievements.