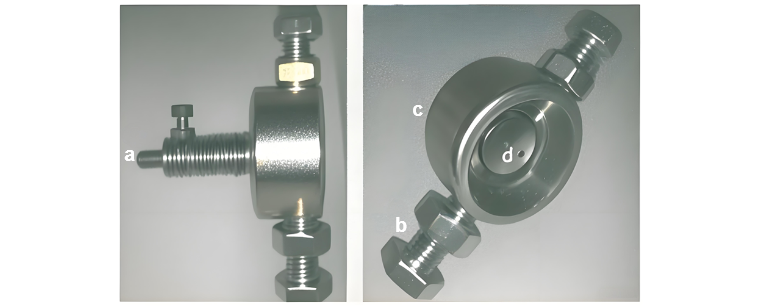

As per the design scheme, a Q235A iron rod with a length of 60 mm and diameter of 40 mm is selected as the blank, which is machined into a circular full - enclosed structure on a lathe. The inner diameter of the front end is processed to 32 mm with a dimensional error controlled within 0.01 mm to ensure precise fitting with the spindle end; the tail is machined into a circular rod with a diameter of 12 mm for sensor connection. Two circular holes with an inner diameter of 8 mm are drilled on opposite sides of the body and tapped to fit the installation of M8 and M10 high - strength bolts.

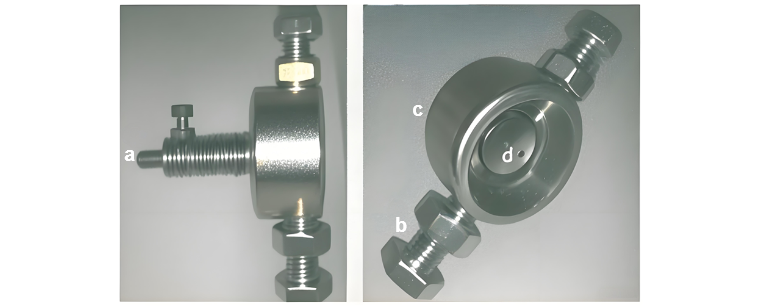

A strong magnetic sheet with a diameter of 16 mm and thickness of 2 mm is purchased. A hole is drilled on the tail circular rod of the body to machine a transition connecting rod for coupling with the shaft coupling. The finished structure is shown in Figure 1:

- Component a: Connects with the shaft coupling to realize reliable fixation of the rotation sensor;

- Component b: The outer diameter of M8/M10 high - strength bolts matches the keyway of the spindle end to eliminate extra rotation of the transition joint;

- Component c: The outer circle of the transition joint matches the spindle outer circle to ensure coaxial alignment between the transition joint and the spindle;

- Component d: The circular thin strong magnet fixes the transition joint to the circuit breaker crank arm spindle via magnetic attraction, overcoming the axial displacement of the sensor caused by vibrations during measurement and effectively suppressing axial movement.

3 Application Effect

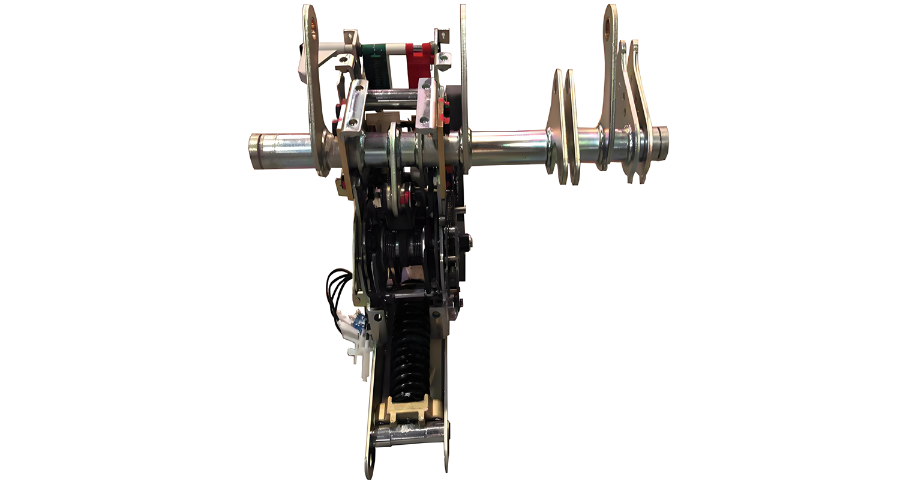

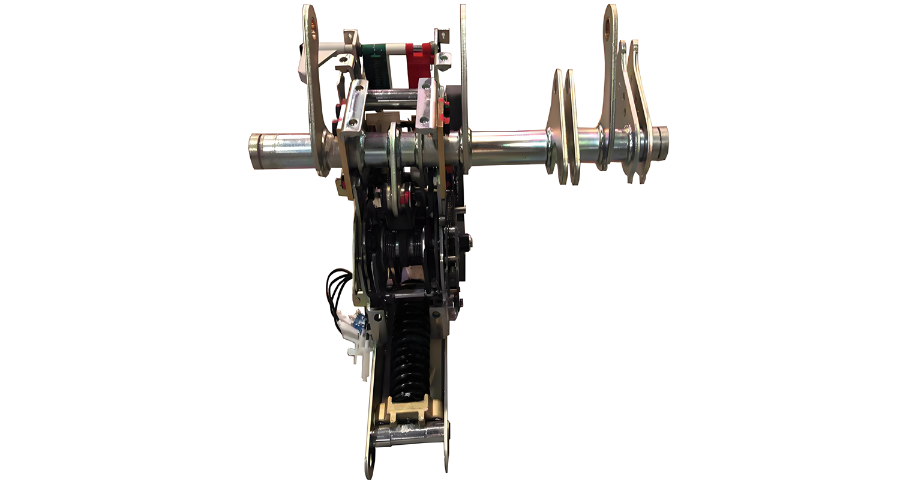

The overall assembly of the rotation sensor was completed using the transition joint, and the field test effect is shown in Figure 3. After the design and manufacture of the rotation sensor transition joint were completed, a VS1 - 12 indoor vacuum circuit breaker with a threaded hole for the rotation sensor transition joint at the shaft end was selected. Using the same circuit breaker mechanical characteristics tester, test comparisons were carried out respectively with the original transition joint and the transition joint for the installation of the rotation sensor with a lead screw.

When compared with the original transition joint, the difference in the three sets of self - inspection measurement data was within 2 decimal places (the actual measurement results retain 1 decimal place), indicating that the stability of this transition joint is good; when compared with the transition joint for lead screw installation, the difference in the three sets of measurement data was also within 2 decimal places (the actual measurement retains 1 decimal place), indicating that the measurement accuracy of its design meets the requirements.

In actual use, the wear of the ends of the M8 or M10 high-strength bolts that fit with the keyway is relatively prominent. Therefore, generally, 2 - 3 spare bolts are provided for each. If there is even a slight rotational clearance, they are replaced immediately. Usually, new bolts need to be replaced after testing about 30 units.