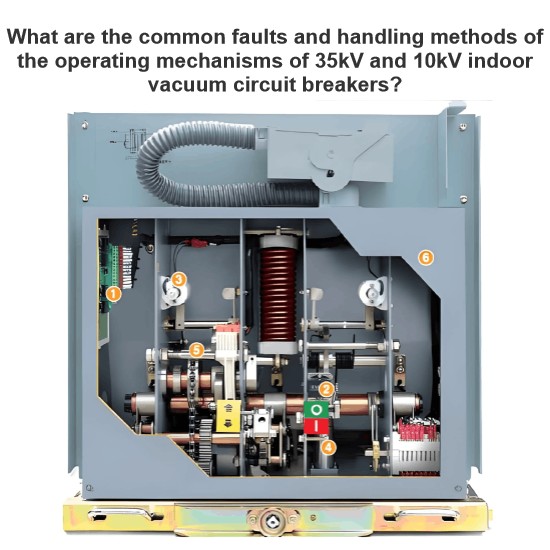

In the technical transformation of the 10kV substation in the East Factory Area, we gained in - depth insights into the structural features of the ZN20 type vacuum circuit breaker. This breaker is primarily composed of an operating mechanism, a box body, vacuum tubes, insulation frames, and insulators. It features a three - dimensional layout with the operating mechanism installed at the front.

Inside the box body made of thin steel plates, the high - voltage components are fixed at the rear. The mechanism connects to the main shaft via connecting plates. As the main shaft rotates, the crank arms fixed on it push the insulators, driving the moving conductive rod of the vacuum tube to perform switching actions. Both closing and opening operations can be manually or electrically controlled through the operating mechanism. Additionally, it is equipped with an AC/DC dual - purpose energy - storage motor, auxiliary contact mechanisms, and an operation counter. Clear "ON" and "OFF" status indicators on the panel facilitate intuitive monitoring of the breaker's operational state.

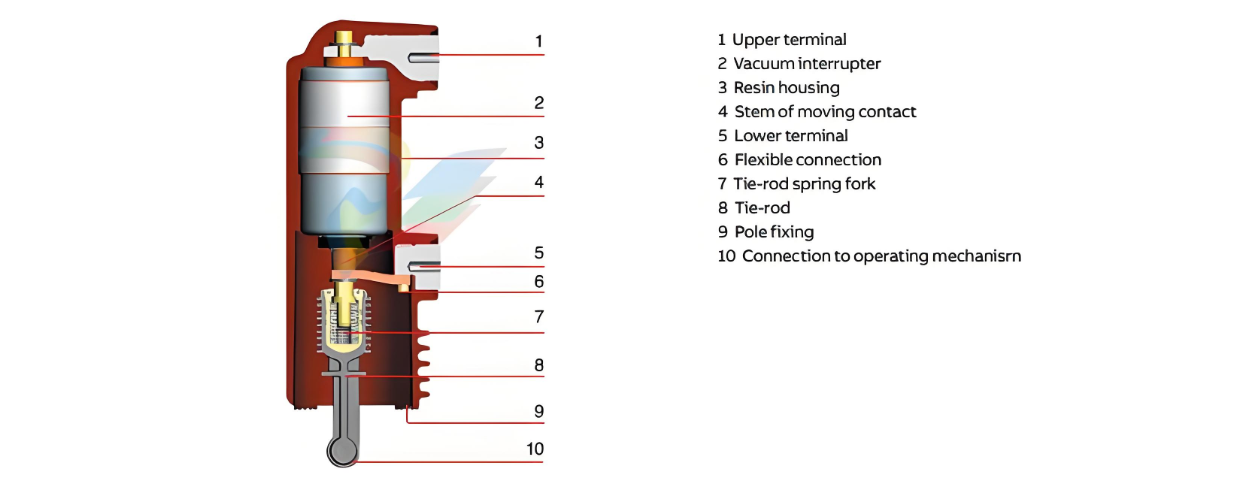

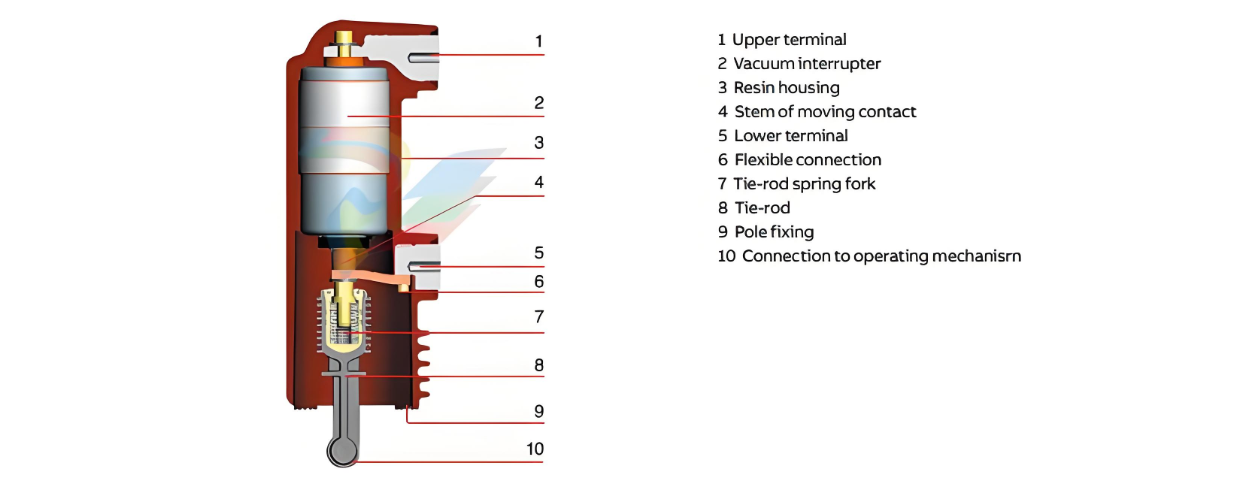

The breaker relies on vacuum tubes to interrupt high - voltage circuits. As shown in Figure 1, a vacuum tube consists of a moving conductive rod, a static conductive rod, moving and static contacts, a shield, a bellows, and a ceramic enclosure. Sealed within the ceramic housing with a high vacuum degree typically ranging from 10⁻⁴ to 10⁻⁷ Torr (Note: The original text "104 - 10⁻⁷ Torr" might be a typo; the correct range should be 10⁻⁴ to 10⁻⁷ Torr), the bellows is welded to the moving conductive rod at one end and the moving end cover at the other. This flexible component enables external operation of the contacts while maintaining complete hermeticity. The shield around the contacts absorbs metal vapor generated by the vacuum arc during current interruption, preventing contamination of the insulation housing.

Through hands - on experience during the transformation project, we deeply appreciate the advantages of vacuum circuit breakers over traditional oil - immersed ones:

- Small contact gap, requiring less operating energy and enabling rapid action.

- Short arcing time and minimal contact erosion when interrupting fault currents.

- Compact size, light weight, and significantly reduced maintenance requirements.

- Fire and explosion resistance, along with low operating noise.

- These benefits are crucial for enhancing the reliability of substation operations and reducing maintenance costs.

Application Effects

As project participants, we deeply understand that the operating mechanism of the vacuum circuit breaker closes the vacuum tube contacts through the elastic energy of the energy-storage spring, which is independent of the manual energy-storage speed, ensuring fast closing performance. The mechanism has three motion states: energy storage, closing, and opening.

The vacuum circuit breaker interrupts current by extinguishing the vacuum arc when the current drops to zero. At the moment the vacuum arc extinguishes, the density of electrons, positive ions, and other particles between the contacts rapidly decreases. Within microseconds, the contact gap essentially restores its original high vacuum degree and exhibits high withstand voltage, capable of withstanding the recovery voltage without breakdown to complete the interruption process. Therefore, even if a high voltage is applied shortly after the current zero-crossing, the contact gap will not break down again—meaning the vacuum arc can be completely extinguished at the first current zero-crossing.

Application Effects

Since the ZN20 10kV high-voltage vacuum circuit breakers were put into operation in June 2007 after the transformation, they have shown excellent performance. The circuit breakers feature fast opening/closing speeds, low operation noise, and accurate and reliable actions.

Compared with the previous oil-immersed circuit breakers, which required frequent refueling and heavy maintenance workload, the vacuum circuit breakers have significantly reduced maintenance tasks and costs, bringing tangible economic benefits. In the over 20 years of operation before the transformation, the substation experienced several misoperation accidents (such as forcibly opening the disconnector while the oil-immersed circuit breaker was in the closed position), causing varying degrees of equipment damage.

After the transformation, the high-voltage switchgear eliminated disconnectors, with each circuit controlled by a single vacuum circuit breaker. When the circuit breaker is opened, the breaker cart can be withdrawn, serving the function of a high-voltage disconnector. Additionally, the switchgear is equipped with mechanical and electrical locks in accordance with the "Five Prevention" requirements, effectively avoiding misoperation accidents, reducing the accident rate, and ensuring safe operation.