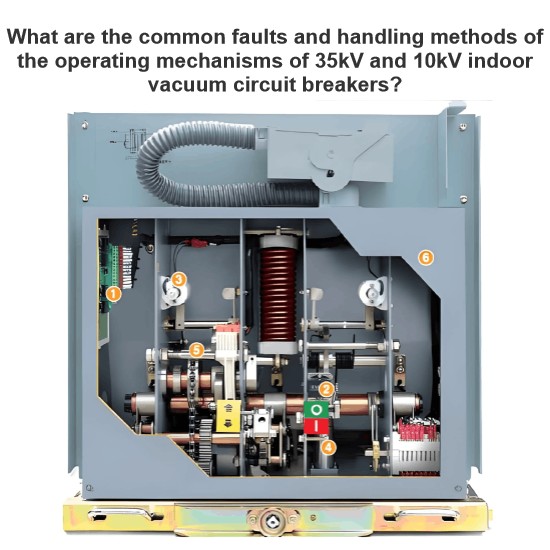

What are the common faults and corresponding solutions for indoor drawer-type high-voltage vacuum circuit breakers?

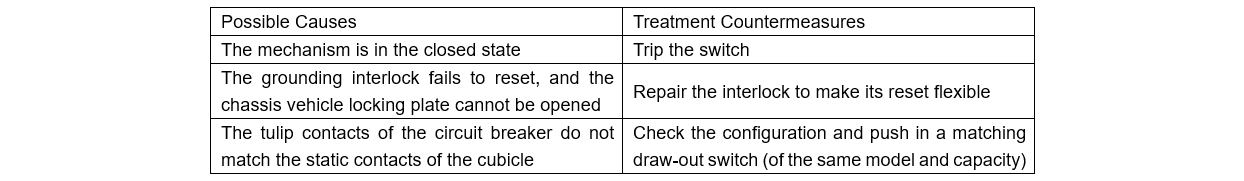

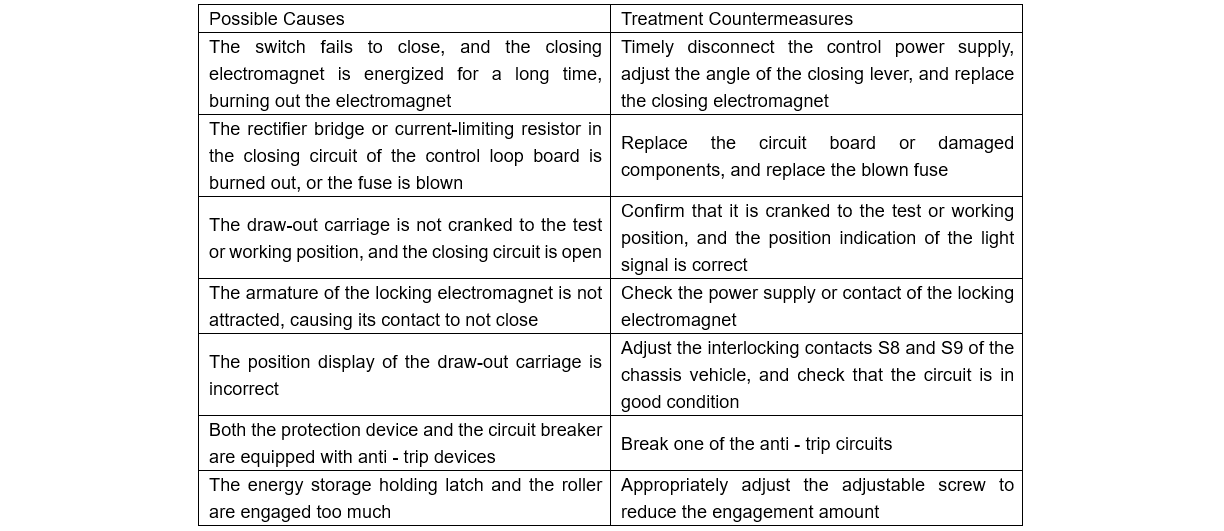

The circuit - breaker fails to close. It manifests as the closing core actuating but the circuit - breaker not closing successfully; or the closing core not actuating, which shows that the control circuit of the circuit - breaker is open - circuited or the mechanism is not charged, etc. Its causes and treatment countermeasures are shown in Table 2.

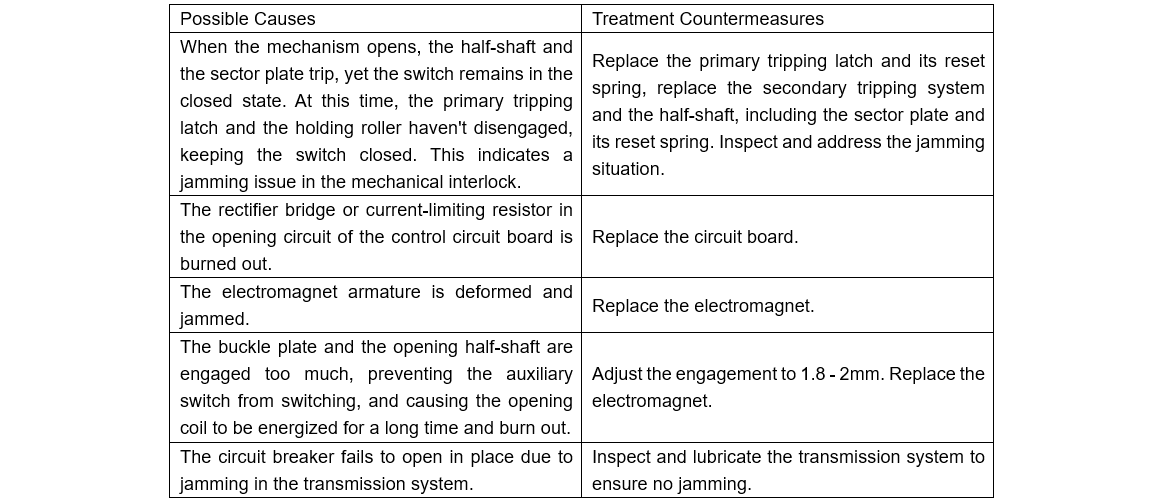

The circuit breaker fails to open. The armature of the electromagnet is deformed and stuck, and the buckle plate and the opening half - shaft are engaged too much; the opening armature acts, but due to the jamming of the transmission system, the circuit breaker fails to open in place. Its causes and treatment countermeasures are shown in Table 3.

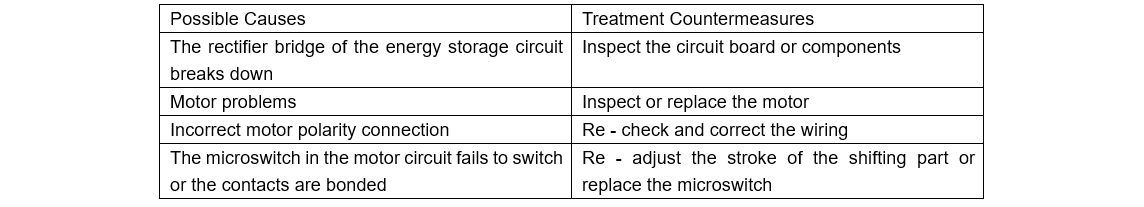

The motor fails to store energy or runs continuously. The main manifestations are that the microswitch in the motor circuit fails to switch, the rectifier bridge in the energy storage circuit is broken down, or the motor is faulty. The causes and treatment countermeasures are shown in Table 4.

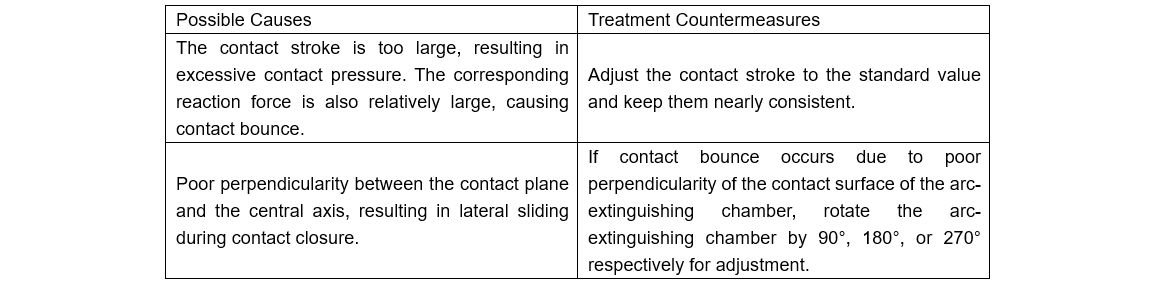

Excessive contact bounce time during closing, with one phase having an oversized contact stroke and three - phase inconsistency, results in excessive contact pressure. The corresponding reaction force increases, causing contact bounce. The causes and treatment countermeasures are shown in Table 5.

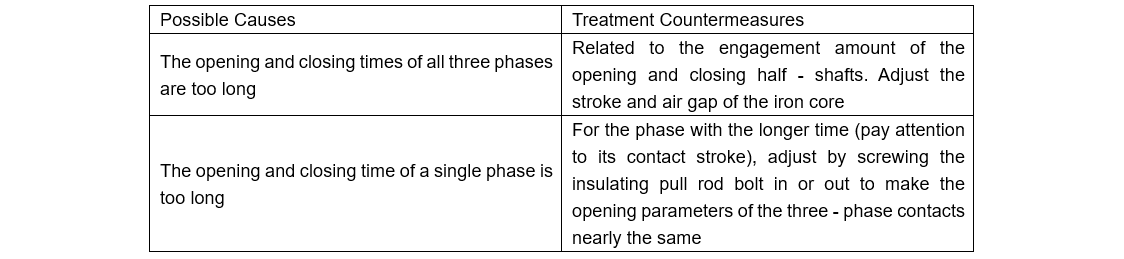

The opening and closing time seriously exceeds the standard. The opening and closing time is related to the engagement amount of the opening and closing half - shafts, as well as the flexibility of the mechanism and the transmission system of the main body. The causes and treatment countermeasures are shown in Table 6.

Preventive Measures

Hey there! I'm an electrical engineer specializing in Failure and Maintenance. I've dedicated my career to ensuring the seamless operation of electrical systems. I excel at diagnosing complex electrical failures, from malfunctioning industrial motors to glitchy power distribution networks. Using state - of - the - art diagnostic tools and my in - depth knowledge, I pinpoint issues quickly. On this platform, I'm eager to share my insights, exchange ideas, and collaborate with fellow experts. Let's work together to enhance the reliability of electrical setups.