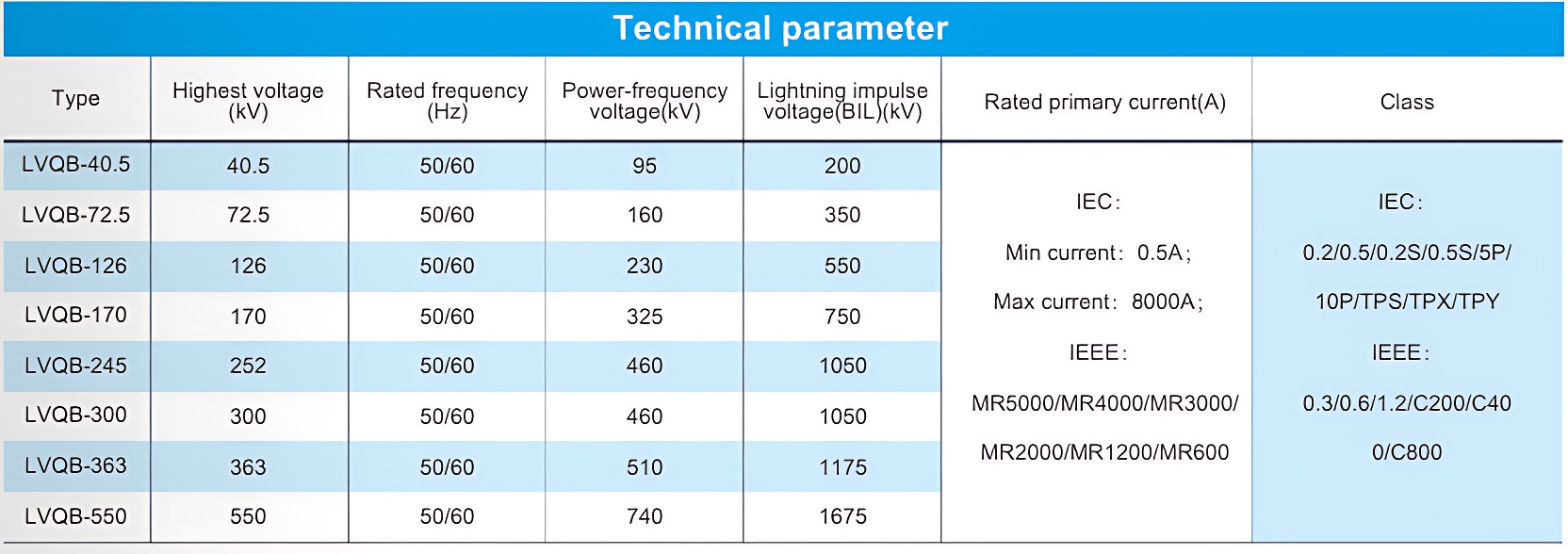

| Brand | Wone |

| Model NO. | LVQB SF6 gas insulated current transformer |

| Rated voltage | 40.5kV |

| Series | LVQB |

Product introduction:

LVQB series current transformers are SF6 gas insulated, inverted structure to meet the IEC/IEEE standard.The series connected transformer in the line has the functions of electricenergy measurement, metering, relay protec tion and transient protection.

Product features:

●The primary winding is of through type conductive rod structure with good dynamic and thermal stability.

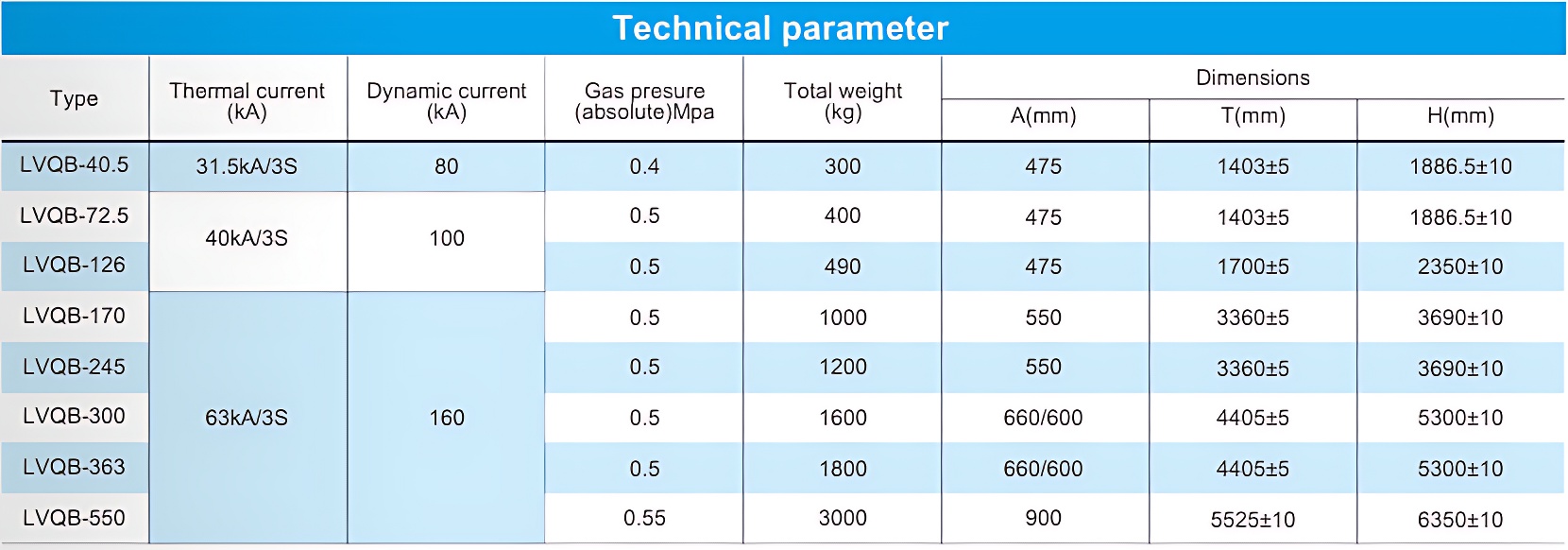

●The maximum thermal stability current is 63kA/3s (when the primary winding is in series).

●The primary winding passes through the center of the secondary winding without the influence of magnetic flux leakage, and the measurement accuracy reaches 0.1 and 0.2s

●The upper shell is of aluminum alloy welding structure, and the top is equipped with a metal explosion-proof disc. If the internal high-energy discharge occurs, when the gas pressure exceeds 1.0MP a, the explosion-proof disc will break, so as to achieve the purpose of pressure release, improve product safety, and there is no danger of explosion.

●The secondary winding is poured into the aluminum shield housing with organic materials, and the measuring and protection lines at the secondary side will not be subject to electrical attack due to insulation breakdown.

●The optimized electrode shielding structure improves the internal and external electric field distribution of the product, and the insulation performance is excellent. The local discharge test is conducted under the power frequency test voltage.

●The cast aluminum footing is directly cast on the external insulating bushing, and the bottom plate bolt is fixed with the footing from the bottom up to avoid water ingress and ponding from the base fastener. The secondary outlet box is cast with stainless steel or aluminum alloy. The dust-proof, waterproof and breathable sealing structure meets the requirements of IP55.

●The secondary terminals for users to connect are Phoenix special terminal blocks, which are more convenient and fast to plug, pull and connect.

●The sealing ring is made of ethylene propylene diene monomer (EPDM) and imported fluor silicone rubber. It is suitable for areas with high and low temperature changes and harsh ambient temperatures. The annual air leak age rate is less than 0.5%.

●The product performance remains unchanged after rigorous transportation vibration test.

●The shell, base and junction box are all made of aluminum alloy. The nameplate is made of stainless steel. All exposed parts will never rust. The base is equipped with a density meter, which can display the gas pressure inside the transformer (the displayed value is automatically converted to the internal gas pressure at 20 ℃) and density. When the internal pressure of the transformer drops to the alarm pressure, it will provide a signal and require gas supplement.

Remark: Approximate dimensions and weights for special requirements, please consult us.