What tests need to be done on voltage transformers?

Practical Experience Sharing from an Electrical Engineer in the Field

By Oliver, 8 Years in the Electrical Industry

Hi everyone, I'm Oliver, and I've been working in the electrical industry for 8 years.

From early involvement in substation commissioning and equipment inspection, to now managing the maintenance and fault analysis of entire power systems, one of the most frequently encountered devices in my work has been the voltage transformer (VT / PT).

Recently, a friend who's just starting out asked me:

“What tests should be done on voltage transformers? And how do you know if there’s a problem?”

Great question! Many field workers only know whether the wiring is connected or if there’s voltage — but to truly understand the health condition of a PT, it requires a series of professional tests.

Today, I’ll share with you in simple language — based on my hands-on experience over the past few years — what kind of tests are typically performed on voltage transformers, why they're important, and how to carry them out.

No complicated jargon, no endless standards — just practical knowledge you can use in real life.

1. Why Perform Testing?

Although a voltage transformer may look simple, it plays three key roles: measurement, metering, and protection.

If something goes wrong, it could lead to:

- Incorrect meter readings;

- Protection misoperation or failure;

- Loss of voltage monitoring across the system.

That’s why regular testing is so important — it’s like giving your PT a full check-up. It helps catch problems early and avoid major incidents.

2. The Five Most Common Types of Tests on Voltage Transformers

Based on my 8 years of field experience, here are the five most commonly used and critical tests:

Test 1: Insulation Resistance Test

Purpose: To check insulation between windings and between windings and ground.

This is one of the most basic and essential tests.

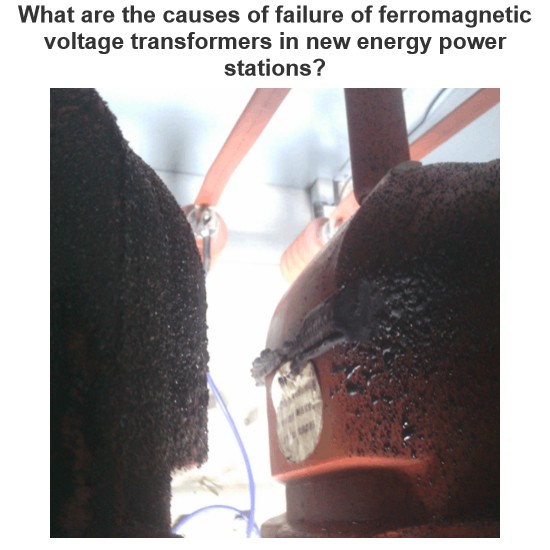

Poor insulation can cause signal interference, short circuits, or even explosions.

How to perform it:

- Use a 2500V megohmmeter for primary to secondary and ground;

- Use a 1000V megohmmeter for secondary to ground;

- Measure insulation resistance between primary and secondary, primary to ground, and secondary to ground;

- Compare with historical data — significant drops mean further investigation is needed.

My advice:

- Must be done on new installations;

- Part of annual preventive maintenance;

- Also test after moisture exposure, lightning strikes, or tripping events.

Test 2: Ratio Test

Purpose: Confirm that the actual voltage ratio matches the nameplate value to ensure accurate measurement and protection.

For example, a PT rated at 10kV/100V must output within tolerance; otherwise, protection relays may misoperate.

How to perform it:

- Apply a known low voltage (e.g., 100V–400V) to the primary side;

- Measure the secondary voltage and calculate the actual ratio;

- Compare with the nameplate — acceptable error is usually ±2%.

My experience:

- A ratio mismatch may indicate inter-turn shorting;

- Sometimes it's just incorrect wiring, such as reversed polarity;

- Always re-test after terminal changes or repairs.

Test 3: Excitation Characteristic Test (Volt-Ampere Curve)

Purpose: Determine if the core is saturated or shows signs of aging or moisture ingress.

This test is especially important for electromagnetic VTs, particularly those in systems prone to ferroresonance.

How to perform it:

- Apply AC voltage to the secondary winding;

- Gradually increase the voltage and record current values;

- Plot the U-I curve and observe the knee point.

Key interpretation:

- A normal curve will show a clear knee point;

- A smooth, non-kinked curve suggests core saturation;

- A steep initial slope may indicate moisture damage.

Real case: I once found abnormal excitation characteristics on a PT — turned out it had water ingress due to poor sealing. After drying, it returned to normal.

Test 4: DC Resistance Test

Purpose: Check for broken strands, turn-to-turn shorts, or poor connections in the windings.

DC resistance testing helps uncover hidden defects inside the windings.

How to perform it:

- Use a DC resistance tester;

- Measure the resistance of both primary and secondary windings;

- Compare results with factory values or previous measurements — deviation should not exceed ±2%.

Important notes:

- Temperature affects results — best to compare under similar conditions;

- On large PTs, allow time for discharge before testing to avoid residual charge errors.

Test 5: Dielectric Loss Factor (tanδ) Test

Purpose: Assess the aging or moisture condition of insulation materials.

This advanced test is often used for high-voltage VTs, especially capacitive voltage transformers (CVTs).

How to perform it:

- Use a tanδ tester;

- Apply a set voltage and measure the dielectric loss factor;

- Typically acceptable value is tanδ ≤ 2% (varies by device).

Common issues:

- High values suggest insulation degradation or moisture;

- If standard isn't met, consider drying or replacement.

3. Additional Auxiliary Testing Methods

In addition to the five main tests, these supplementary methods are also useful:

Infrared Thermal Imaging

- Detect overheating at connection points;

- Identify hotspots early;

- Especially useful for monitoring operating equipment.

Partial Discharge Detection

- Detect weak internal discharges;

- An effective early warning for insulation degradation;

- Recommended for high-voltage PTs in critical applications.

Wiring Inspection + Polarity Test

- Ensure correct wiring and consistent polarity;

- Prevent metering inaccuracies or protection misoperations.

4. My Final Suggestions

As someone with 8 years of field experience, I want to remind all professionals:

“Don’t wait until the voltage transformer fails before thinking about testing.”

Performing regular comprehensive checks every year not only ensures stable system operation but also greatly extends the life of your equipment.

Here are my recommendations for different roles:

For Maintenance Personnel:

- Learn to use basic instruments (megohmmeters, multimeters, ratio testers);

- Understand each test procedure and standard;

- Record test data regularly and build comparison records.

For Technical Staff:

- Master advanced tests like excitation curves and tanδ;

- Combine infrared and partial discharge detection to improve diagnostics;

- Understand the PT’s role in the system to avoid blind operations.

For Managers or Procurement Teams:

- Clarify testing requirements during equipment selection;

- Request complete factory test reports from suppliers;

- Establish lifecycle management and schedule regular inspections.

5. Closing Thoughts

Voltage transformers may seem small, but they play a crucial role in the entire power system.

They’re not just about stepping down voltage — they’re the eyes of the system, the ears of protection, and the heart of metering.

After 8 years in the electrical field, I often say:

“Details determine success or failure, and testing ensures safety.”

If you ever encounter abnormal PT behavior, unusual test results, or don’t know how to diagnose a problem, feel free to reach out — I’m happy to share more hands-on experience and solutions.

May every voltage transformer run stably and safely, safeguarding the accuracy and reliability of our power grid!

— Oliver

Hey! I'm Oliver Watts, an electrical engineer in Inspection and Testing. With years of hands - on experience, I ensure electrical systems meet top safety and performance standards. Using advanced gear, I conduct diverse tests, easily spotting issues in both large - scale industrial and small - scale commercial setups. I love teaming up, sharing knowledge, and keeping up with industry regs. Also, I'm skilled at data analysis with software. If you're into electrical inspection or just want to chat engineering, reach out. Let's connect and explore!