High - voltage SF₆ circuit breakers are the most widely used switchgear in substations. Regular inspection and maintenance of them are crucial for ensuring the stable operation of the power system. However, in the substation maintenance field, especially during the maintenance of high - voltage SF₆ circuit breakers, there are numerous hazard points (such as poisoning, electric shock, etc.), which seriously threaten the personal safety of workers. Based on this, this paper analyzes from the perspective of location and safety control technologies, aiming to improve the safety of substation maintenance operations and reduce the accident rate.

1 Analysis of Working Principles and Characteristics

1.1 Physical and Chemical Properties of SF₆ Gas

The SF₆ molecule is composed of one sulfur atom and six fluorine atoms, with an atomic weight of 146.06, 5.135 times heavier than air. Below 150°C, SF₆ gas exhibits good chemical inertness and does not chemically react with common metals, plastics, and other materials in circuit breakers. Therefore, it is regarded as a colorless, odorless, non - toxic, and transparent non - combustible gas, which is generally difficult to decompose (insoluble in transformer oil and sparingly soluble in water). However, through the opening and closing operations of switches, SF₆ gas undergoes partial decomposition under the action of discharge and arcs, forming decomposition products in gaseous or powdery form, such as metal fluorides, SOF₂, SO₂F₄, etc., which are extremely harmful to the human body. Among them, SF₆ gas decomposes and dissociates under the action of arcs (molecules with a polyatomic structure decompose into single atoms or charged particle gases), and the internal changes enhance its thermal and electrical conductivity.

1.2 Working Principle of High - voltage SF₆ Circuit Breakers

The SF₆ circuit breaker is composed of three vertical porcelain insulator units, each with a gas - blast arc - extinguishing chamber. This design makes the circuit breaker compact, while having good insulation and arc - extinguishing performance. The gas - blast arc - extinguishing chamber is the core component of the high - voltage SF₆ circuit breaker, and it is filled with SF₆ gas through pipes connected to the three arc - extinguishing chambers. When the circuit breaker is opened, the controllable contact separates from the fixed contact, generating an arc. At this time, the SF₆ gas in the arc - extinguishing chamber quickly blows towards the arc through the pipes, using the gas's insulation and arc - extinguishing properties to quickly extinguish the arc. In addition, the spring operating mechanism and its single - box control equipment are key components for driving and controlling the movement of the contacts of the high - voltage SF₆ circuit breaker. It is usually composed of springs, connecting rods, transmission mechanisms, microprocessors, or programmable logic controllers. When the circuit breaker needs to be opened or closed, the control equipment issues an instruction to make the spring operating mechanism act and drive the movable contact to move accordingly.

1.3 Performance Characteristics of High - voltage SF₆ Circuit Breakers

Compared with air and transformer oil, SF₆ gas has the characteristics of high insulation strength, excellent arc - extinguishing performance, and small volume, and has broad application prospects in the high - voltage power field.

- Blocking effect: It gives full play to the arc - blowing effect of the gas flow. The arc - extinguishing chamber is small in size, simple in structure, large in breaking current, short in arcing time, has no reignition when breaking capacitive or inductive current, and has low over - voltage.

- Long electrical life: It can continuously break 19 times at a full capacity of 50kA, with a cumulative breaking current of 4200kA, a long maintenance cycle, and is suitable for frequently - operated scenarios.

- High insulation strength: SF₆ gas can pass various insulation tests with a large margin under 0.3MPa. After the cumulative breaking current reaches 3000kA, each breaking port can withstand a power - frequency voltage of 250kV within 1 minute under 0.3MPa, and can still withstand a power - frequency voltage of 166.4kV when the SF₆ gas pressure is reduced to zero gauge pressure.

- Good sealing performance: The water content of SF₆ gas is relatively low. The arc - extinguishing chamber, resistors, and supports can be divided into independent gas compartments to prevent dirt and moisture from entering the interior of the circuit breaker.

- Small operating power and smooth buffering: The transmission ratio between the working cylinder of the mechanism and the arc - extinguishing contact is 1∶1, and the mechanism has stable characteristics. The stability of the mechanism characteristics can reach 3000 times (10000 times in the test environment), and the operating noise is less than 90dB.

2 Analysis of Hazard Points in Substation Maintenance Sites

2.1 Types and Characteristics of Hazard Points

Hazard points in substation maintenance sites mainly include four types: electrical hazards, mechanical hazards, chemical hazards, and environmental factors. These hazard points may directly or indirectly threaten the personal safety of maintenance personnel.

- Electrical hazards: Caused by equipment insulation damage or operational errors, mainly manifested as high voltage and arcs. Since the circuit breaker carries high voltage during operation and has capacitive and inductive effects, residual charges may still exist even when it is in the open - circuit state, leading to electric shock injuries. Arcs may generate high temperatures and cause fires.

- Mechanical hazards: The hazards mainly come from the mechanical components of the equipment. If not properly operated and maintained, one may be pinched or bumped by rotating or moving parts.

- Chemical hazards: SF₆ gas is stable at room temperature, but it begins to decompose under the action of arcs, corona, etc. Inhaling the generated gas may cause dizziness, pulmonary edema, or even death.

- Environmental hazards: Performing maintenance in weather such as thunderstorms and strong winds not only increases the difficulty of maintenance work but also brings uncontrollable risks to maintenance personnel. In addition, problems such as poor ventilation and small space in the maintenance environment may also increase the danger of on - site maintenance.

2.2 Analysis of the Causes of Hazard Points

The causes of hazard points in substation maintenance sites mainly include equipment - related, human - related, and environmental factors. With the increase in the number of maintenance operations, the degree of equipment wear and tear increases, leading to a decline in electrical performance and a higher risk of accidents.

Due to the uneven quality of maintenance personnel, some of them lack sufficient understanding of the equipment structure and working principles, and may be negligent during actual operations. For example, due to a lack of sufficient vigilance, personnel may accidentally touch live parts or use tools inappropriately, which may directly trigger safety accidents.

For SF₆ circuit breakers, the hazards mainly stem from their chemical properties. Toxic substances generated under specific conditions are likely to accumulate indoors due to environmental limitations, further increasing the level of danger.

3 Hazard Point Location and Safety Control Technologies

3.1 Hazard Point Location Methods

- Fiber optic sensing technology: Fiber optic sensing technology has excellent insulation performance and anti - electromagnetic interference ability. It can effectively monitor the structural health and electrical parameters of SF₆ circuit breakers, collect and analyze data in real - time, and promptly detect potential faults and safety hazards.

- Wireless sensor network: A wireless sensor network is composed of a large number of sensor nodes. Its main purpose is to monitor environmental parameters, equipment status, and the location information of maintenance personnel in real - time. The network has the characteristics of self - organization, self - adaptation, and anti - interference, and can adapt to the complex and changeable environmental conditions on - site, realizing real - time monitoring and location of hazard points.

- Machine vision and infrared thermal imaging technology: Machine vision technology can identify and locate potential hazard points, such as exposed cables and damaged equipment, by capturing and analyzing on - site images; while infrared thermal imaging technology can monitor the temperature distribution of equipment in real - time and accurately locate fault points and potential risk points.

3.2 Hazard Point Prediction Model Based on Data Analysis

At present, intelligence, digitalization, automation, and integration are the main trends of China's power grid, and the application of artificial intelligence and big data technologies has accelerated this development process. During the maintenance of SF₆ circuit breakers, a hazard point prediction model based on data analysis is established, which mainly includes four steps: data collection, data preprocessing, feature engineering, and model training.

- Data collection: Obtained through various sensors, operation records of monitoring equipment, etc. To improve the accuracy of the model, a large amount of comprehensive data should be collected as much as possible.

- Data preprocessing: Preprocess the original data (outlier detection and processing, data transformation, etc.) to improve data quality and lay the foundation for subsequent feature engineering and model training.

- Feature engineering: After preprocessing is completed, useful features for hazard point prediction need to be selected from a large amount of data. These features should have good discrimination and predictive ability to improve the accuracy of the model.

- Model training: SVM (Support Vector Machine) is a commonly used classification and regression analysis method. It separates different categories of data by finding the optimal hyperplane, maximizing the classification interval between the two types of data.

3.3 Safety Control Technology Strategies

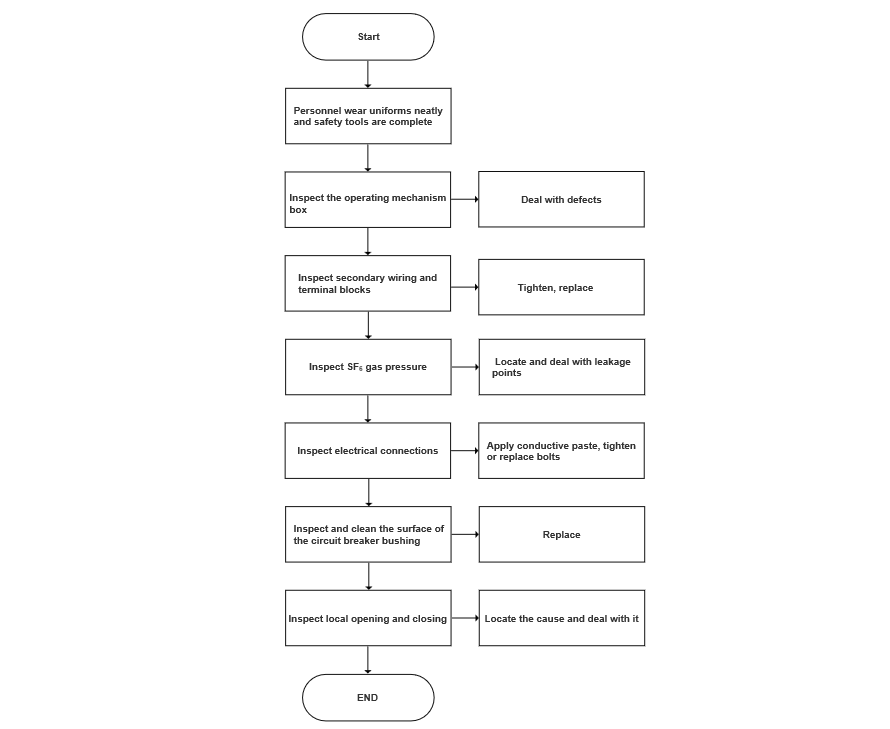

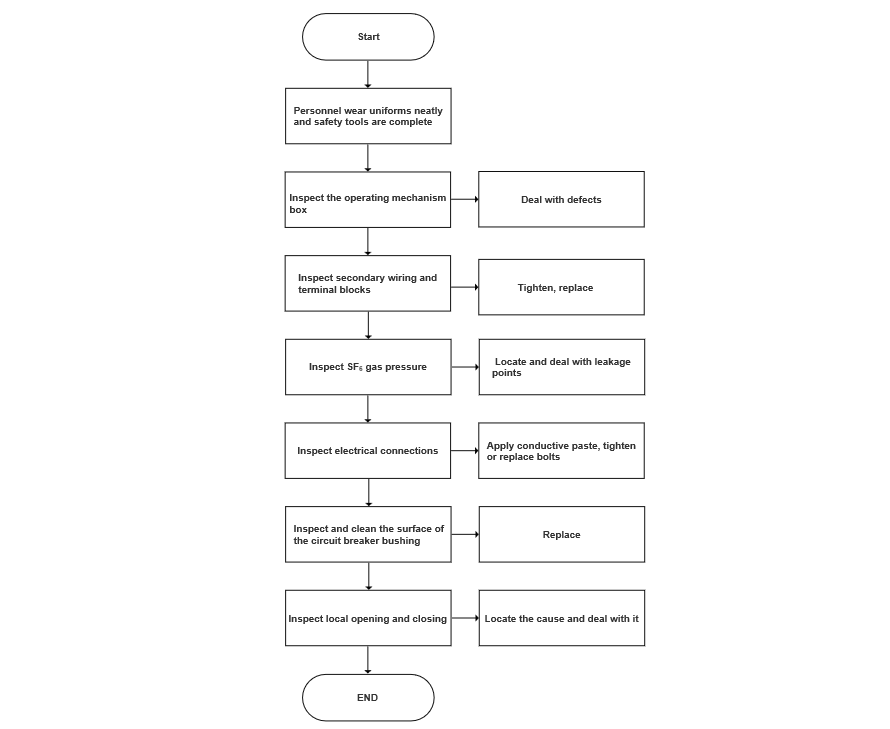

To improve the accuracy and practicality of location technologies, big data and artificial intelligence technologies should be utilized, and machine learning algorithms should be applied to intelligently identify and predict hazard points in substation maintenance sites, providing more accurate location information for maintenance personnel and reducing the risk of accidents. In substation maintenance sites, data from various sensors should be fused to improve the accuracy of location and the accuracy of the model. Applying augmented reality (AR) technology, which integrates virtual information with the real world, can enable maintenance personnel to better understand the equipment structure and thus solve the problem of operational errors. Relevant parties should strengthen the management of on - site maintenance work and strictly follow the operation procedures for maintenance (see Figure 1). At the same time, develop intelligent wearable devices for maintenance personnel to obtain their location information in real - time and monitor them in real - time to ensure safety.

4 Conclusion

In substation maintenance sites, accurately identifying and locating hazard points is the key to ensuring the safety of SF₆ circuit breaker maintenance sites. Through in - depth research on the working principles and characteristics of SF₆ circuit breakers, it is found that chemical factors are the main non - negligible hazard points during their maintenance process. To effectively deal with risks, new technologies, new concepts, and new methods should be used for pre - event prevention, predicting potential risks in advance, and providing early - warning information for maintenance personnel to ensure the smooth progress of maintenance operations.