What are Line Supports?

Definition

Line supports refer to various structures, such as poles or towers, that are employed to uphold overhead power lines or wires. These structures play a crucial role in power transmission. They ensure appropriate spacing between conductors and maintain a prescribed distance between the conductors and grounded components. Additionally, they uphold the specified ground clearance, which is determined by electrical and mechanical considerations.

Types of Line Supports

The key requisites for line supports are low cost, minimal maintenance expenses, and a long service life. Line supports can be fabricated from wood, concrete, steel, or aluminium. They are mainly categorized into two types:

- Electrical Pole

- Electrical Tower

The details of these types are elaborated below.

1. Electrical Pole

An electrical pole is a structure used to support transmission lines with relatively low voltages (not exceeding 115 kV). It is typically constructed from wood, concrete, or steel. Electrical poles can be further divided into three main subtypes, which are described in detail as follows.

Types of Electrical Poles

The selection of an electrical pole hinges on factors such as cost, environmental conditions, and the voltage of the line. Electrical poles are mainly classified into the following types:

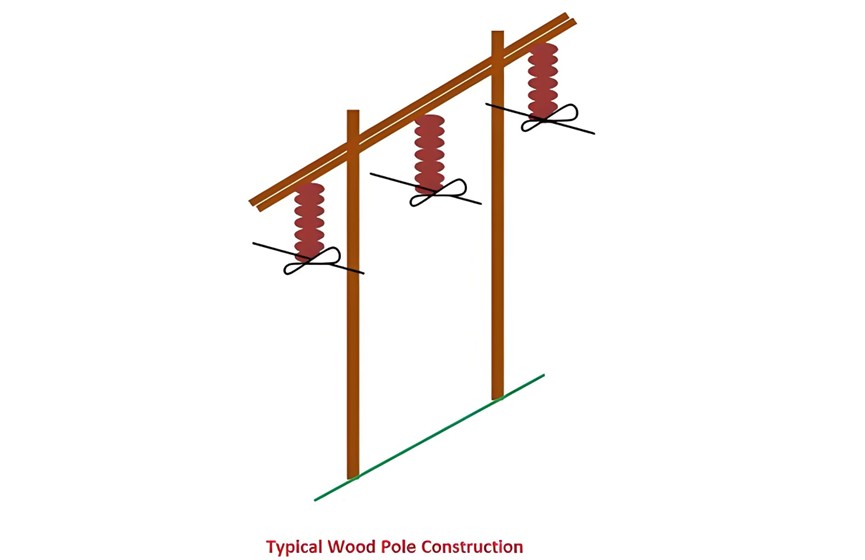

a. Wood Poles

Wood poles are among the most cost - effective line supports and are suitable for lines with short spans and low tension. However, they have limitations in terms of height and diameter. When greater strength is needed, double - pole structures in the form of A - type or H - type are utilized.

Wood Poles

Wood poles possess a natural insulating characteristic, which reduces the likelihood of flashovers caused by lightning. However, a significant drawback is that their strength and durability are somewhat unpredictable.

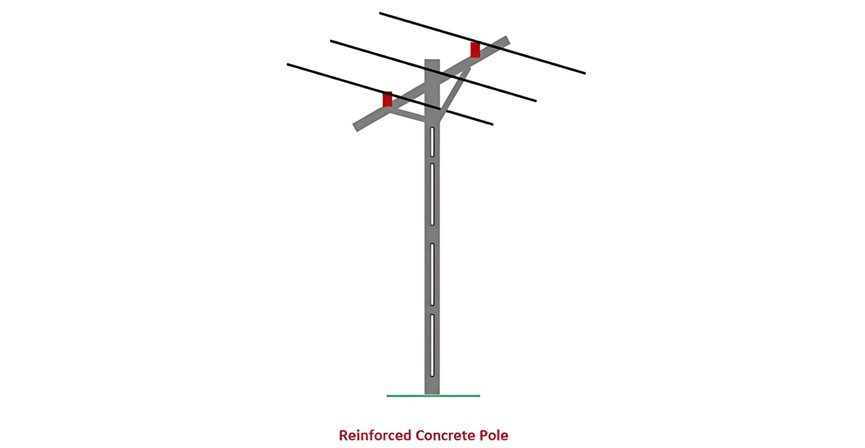

Concrete Poles

Concrete poles offer enhanced strength compared to wood poles and are often used as a substitute. They have a longer lifespan due to minimal degradation and also feature low maintenance costs. Nevertheless, concrete poles are quite heavy, and their brittle nature makes them vulnerable to damage during loading, unloading, transportation, and the erection process.

The challenges associated with handling and transporting concrete poles can be mitigated through the use of pre - stressed concrete supports. These can be manufactured in sections and then assembled at the construction site. Pre - stressed concrete poles are not only more durable but also require less material compared to other types of poles.

Steel Poles

For low - and medium - voltage applications, tubular steel poles or Grider steel supports are commonly employed. Steel poles allow for longer spans, but they need to be regularly galvanized or painted to protect against corrosion, which results in high maintenance costs.

Electrical Towers

An electrical tower is a structure designed to carry high - voltage (above 230 kV) transmission lines. These towers are typically constructed from aluminium or steel, materials that provide the necessary strength to support heavy electrical conductors. Electrical towers can be broadly categorized into several types, as described below.

Types of Supporting Towers

High - voltage and extra - high - voltage lines demand significant air and ground clearances. They also involve substantial mechanical loading and insulation costs. To address these requirements, the towers used for such lines often feature long spans. Long - span construction can significantly reduce insulation costs since fewer supports are needed. These towers, usually made of steel or aluminium, also have a reduced likelihood of breakdown. They are classified as follows:

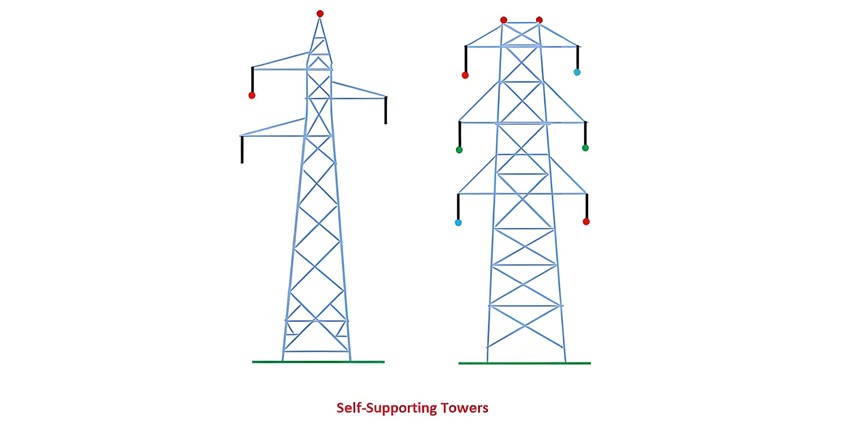

a. Self - Supporting Towers

Self - supporting towers can be further divided into two sub - categories: wide - base and narrow - base towers. Wide - base towers typically feature a lattice (criss - cross) structure with roasted connections, and each leg has its own independent foundation. Narrow - base designs, on the other hand, utilize a lattice (criss - cross) construction made from angle, channel, or tubular steel sections, which are connected either by bolts or welding. Self - supporting towers can also be classified based on their function:

- Tangent Tower: Used for straight sections of the transmission line, these towers are typically equipped with suspension insulators.

- Deviation Tower: Employed when the transmission line changes direction.

For these towers, strain insulators are utilized. They have a wider base and stronger structural components, and are more expensive compared to tangent towers. Narrow - based designs consume less steel or aluminium than wide - base towers, yet their foundation costs are higher. The choice between the two is determined by factors such as material costs, foundation expenses, and right - of - way requirements.

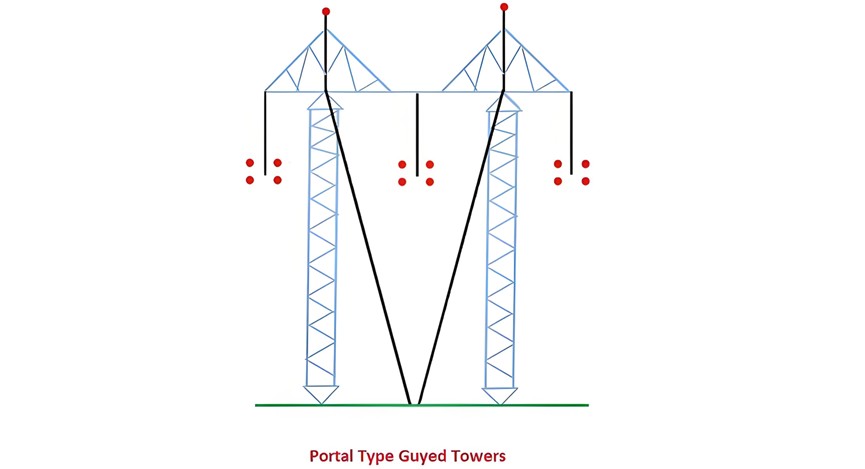

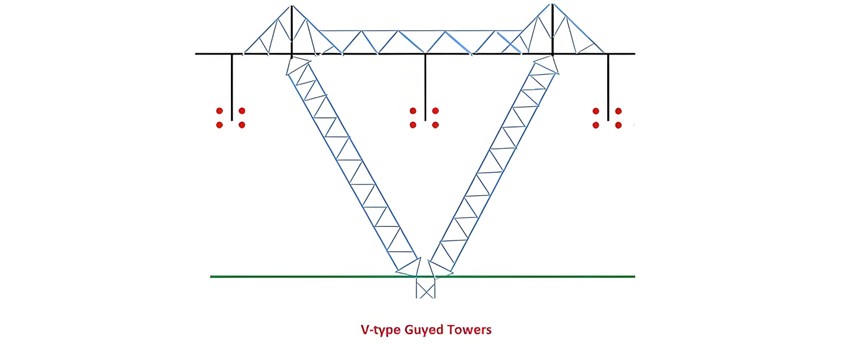

b. Guyed or Stayed Towers

These towers are typically either of the portal type or V - type. In both cases, they feature two supports that are joined at the top by a cross - arm and are equipped with four guy wires.

In the portal - type guyed or stayed tower structure, each support is independently anchored to its own foundation. This design provides a stable and individual base for each upright component. In contrast, the V - support structure has a more distinctive configuration. Here, the two supports meet and rest at an angle to each other, sharing a single, more robust thrust footing. This single - footing design, while different from the portal structure's independent foundations, offers a unique solution for distributing the tower's load and ensuring stability, though it requires a more substantial and specialized foundation due to the concentrated forces acting upon it.

The strength of these double - pole constructions can range from two to four times that of a single pole. The H - type construction is commonly used for four - terminal poles or those supporting switchgear and transformers.