What are the possible causes of cracking failure in CT terminal blocks within GIS equipment?

Felix Spark

07/07/2025

Topics

Hey there! I'm an electrical engineer specializing in Failure and Maintenance. I've dedicated my career to ensuring the seamless operation of electrical systems. I excel at diagnosing complex electrical failures, from malfunctioning industrial motors to glitchy power distribution networks. Using state - of - the - art diagnostic tools and my in - depth knowledge, I pinpoint issues quickly. On this platform, I'm eager to share my insights, exchange ideas, and collaborate with fellow experts. Let's work together to enhance the reliability of electrical setups.

What to Pay Attention to When Selecting and Installing GIS Current Transformers?

Hi everyone, I'm James, and I've been working with current transformers (CTs) for 10 years. Today, I’ll talk about what you need to watch out for when selecting and installing GIS current transformers.Part 1: Key Considerations During Selection1. Accuracy ClassProtection-grade CTs: Used for relay protection — focus on overload capacity and transient response.Metering-grade CTs: Used for billing purposes — require high accuracy, usually 0.2S or 0.5S class.2. Rated Primary Curren

James

07/07/2025

Selection of Primary Verification Circuit and Parameter Measurement for UHV GIS Current Transformers

In UHV GIS, current transformers are key to electric energy metering. Their accuracy determines power trade settlements, so on - site error verification perJJG1021 - 2007is needed. On - site, use power supplies, voltage regulators, and current boosters. Due to encapsulation in GIS, build test circuits via exposed grounding knives, bushings, and return conductors; right circuits simplify wiring and boost accuracy.Challenges like large test current, long circuits, and high impedance exist, but rea

Oliver Watts

07/07/2025

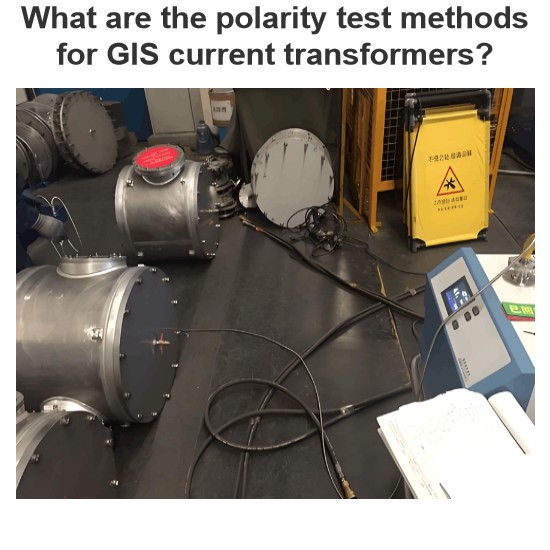

What are the polarity test methods for GIS current transformers?

I’m Oliver, an 8 - year current transformer testing pro. Today, let’s break down new and old polarity test methods for GIS current transformers—how they work and their pros/cons.1.Testing Methods1.1New MethodPre - test ops: Open FDS21/FDS22 fast disconnectors + DS23 disconnector. Close CB21 breaker, then ES21/ES22 grounding disconnectors. Disconnect ES21’s SF6 - shell ground.Wiring: Connect battery between ES21’s moving contact (negative grounded) + ground electrode

Oliver Watts

07/07/2025

Exploring the Design and Application of Photoelectric Current Transformers in GIS

1.Design and Application Example of Photoelectric Current Transformer in GISThis article takes a 126kV GIS project as a specific example to deeply explore the design ideas and practical application of photoelectric current transformers in the GIS system. Since this GIS project was officially put into operation, the power system has remained stable, with no major failures occurring, and the operation status is relatively ideal.1.1 Design and Application Ideas of Photoelectric Current TransformerI

Dyson

07/07/2025