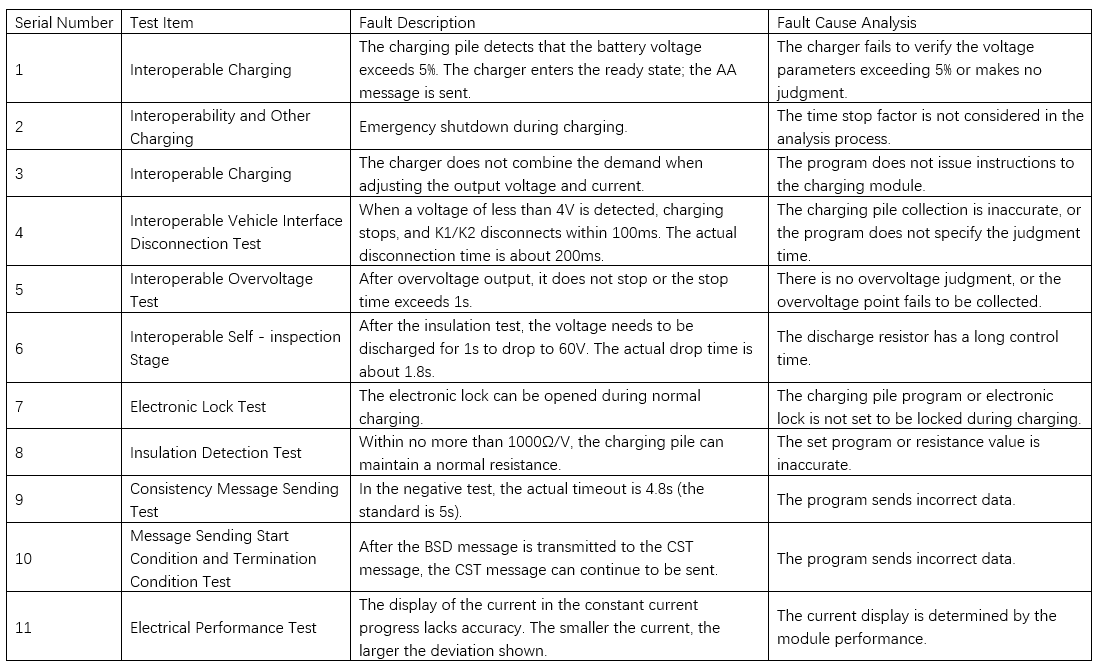

Electric Vehicle Charging Pile Testing Technologies and Failure Analysis

Oliver Watts

06/23/2025

Topics

Hey! I'm Oliver Watts, an electrical engineer in Inspection and Testing. With years of hands - on experience, I ensure electrical systems meet top safety and performance standards. Using advanced gear, I conduct diverse tests, easily spotting issues in both large - scale industrial and small - scale commercial setups. I love teaming up, sharing knowledge, and keeping up with industry regs. Also, I'm skilled at data analysis with software. If you're into electrical inspection or just want to chat engineering, reach out. Let's connect and explore!

What tests are required for dry-type transformers?

1 Pre - commissioning InspectionAs a front - line tester, before formally commissioning a dry - type transformer, I need to carry out a comprehensive and systematic inspection. First, I conduct a visual inspection of the transformer body and its accessories, carefully checking for mechanical damage or deformation. Then, I check whether the leads of the high - and low - voltage windings are firmly connected and whether the bolt tightening torque meets the standard requirements (usually 40 - 60N&m

Oliver Watts

07/01/2025

A Novel Detection Method for Stuck Faults in Load Switches

In recent years, as distribution automation advances, load switches see wider use in distribution lines. Yet, mechanical - failure - induced accidents are on the rise, burdening line operation and maintenance.Poor mechanical performance is the main cause of switch faults. Many scholars study large - scale switchgear operation, using methods like coil current detection, vibration signal analysis, switch travel testing, ultrasonic flaw detection, and infrared thermometry. Motor - current - based s

Oliver Watts

06/30/2025

What tests need to be conducted for load switches?

As a technician with years of on-site experience in power testing, I understand the importance and complexity of load switch testing. Below, I combine practical work experience to elaborate on the full process of load switch testing, from testing items and methods to equipment and procedural specifications.I. Routine Electrical Performance Testing(1) Loop Resistance TestLoop resistance is a core indicator for evaluating a load switch's conductivity. I strictly follow GB/T 3804 and GB 1984 standa

Oliver Watts

06/28/2025

What does the testing of photovoltaic transformers involve?

1. Specificities and Testing Requirements of Photovoltaic TransformersAs a new energy systems technician, I recognize photovoltaic transformers' unique design and application traits: Inverter - output AC carries abundant 5th/7th - order odd harmonics, with PCC harmonic current distortion reaching 1.8% (higher voltage distortion under low load), causing winding overheating and accelerated insulation aging. Photovoltaic systems use TN - S grounding, requiring reliable N - phase output from the sec

Oliver Watts

06/27/2025