What are the causes of current transformer faults and the countermeasures for faults?

Felix Spark

07/03/2025

(2) Emergency Handling (Safety First)

- Power Off: Immediately cut power for safety.

- Inspect Secondary Circuit: Check for open circuits, minimize primary current, use insulation gear, and follow diagrams.

For secondary open circuits:

(3) Detection Techniques

Topics

Hey there! I'm an electrical engineer specializing in Failure and Maintenance. I've dedicated my career to ensuring the seamless operation of electrical systems. I excel at diagnosing complex electrical failures, from malfunctioning industrial motors to glitchy power distribution networks. Using state - of - the - art diagnostic tools and my in - depth knowledge, I pinpoint issues quickly. On this platform, I'm eager to share my insights, exchange ideas, and collaborate with fellow experts. Let's work together to enhance the reliability of electrical setups.

Testing of Optical Current Transformers (OCT)

With the development of modern economy and science and technology, photoelectric current transformers (PECTs) have fully transitioned from the trial operation stage to practical application. As a front - line testing personnel, I deeply feel their importance in the power system during daily work. I also realize the necessity of conducting in - depth research on their testing systems and calibration methods. This not only promotes the engineering application of PECTs but also enables the accurate

Oliver Watts

07/03/2025

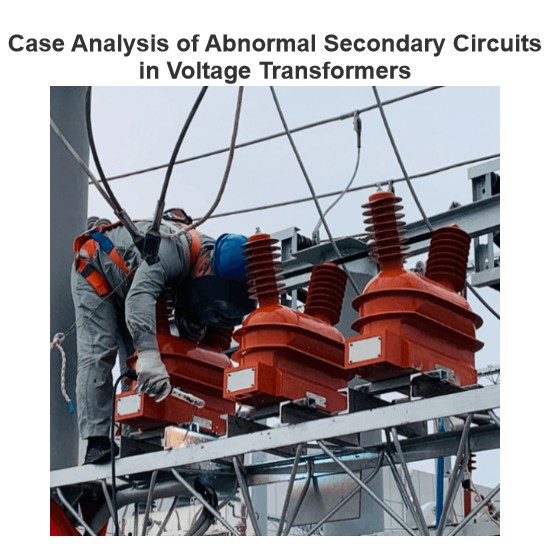

Case Analysis of Abnormal Secondary Circuits in Voltage Transformers

1. Fault SituationIn September 2023, as a front - line fault maintenance worker, I detected abnormal voltage on the 10kV Section I bus of a substation during monitoring duty and informed the operation and maintenance team. The monitoring system showed: U0 = 0 kV, Ua = 6.06 kV, Ub = 5.93 kV, Uc = 6.05 kV, Uab = 10.05 kV, Ubc = 5.94 kVMy team and I rushed to the site. We suspected the secondary air circuit breaker of the 10kV Section I bus voltage transformer was closed and found the U - phase fus

Felix Spark

07/02/2025

What are the causes of failure of ferromagnetic voltage transformers in new energy power stations?

By Felix, 15 Years in the Electrical IndustryHi everyone, I'm Felix, and I've been working in the electrical industry for 15 years.From early involvement in traditional substation commissioning and maintenance to now managing electrical system operations for multiple photovoltaic and wind power projects, one of the most frequently encountered devices I deal with is the Electromagnetic Voltage Transformer (PT).The other day, a shift operator at a new energy plant asked me:“We have an electr

Felix Spark

07/02/2025

What are the reasons for low insulation at the low-voltage side of a dry-type transformer?

Hi everyone, I’m Felix, and I’ve been working in electrical equipment fault repair for 15 years.Over these years, I’ve traveled across factories, substations, and distribution rooms all over the country, troubleshooting and repairing all kinds of electrical equipment. Dry-type transformers are among the most common devices we deal with.Today, a friend asked me:“What does it mean when the low-voltage side of a dry-type transformer has low insulation resistance?”Great

Felix Spark

07/01/2025