| Brand | Schneider |

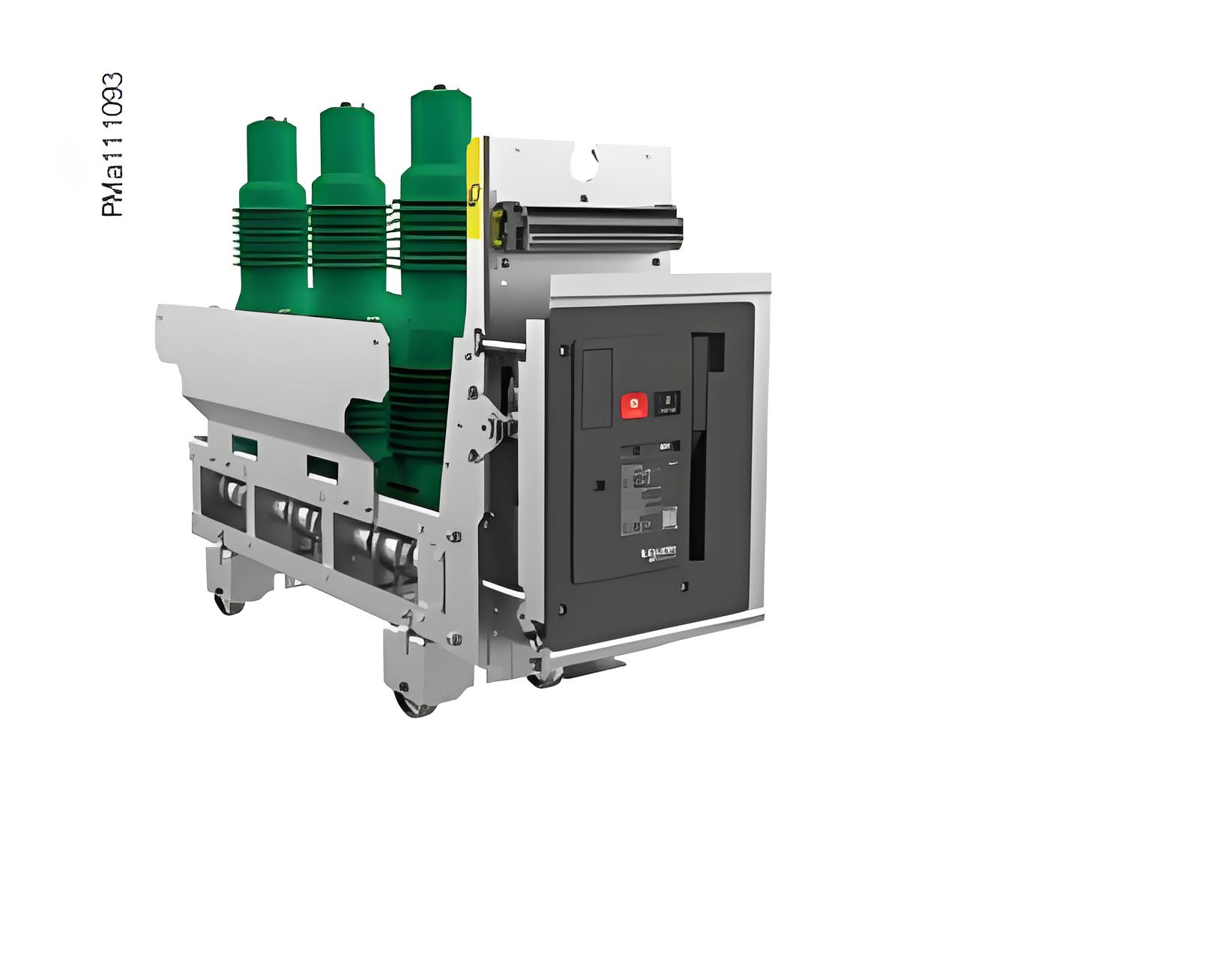

| Model NO. | SM AirSeT Fully air insulated switchgear up to 24 kV |

| Rated normal current | 630A |

| Series | SeT Series |

Overview

The experience of a world leader

Schneider Electric's experience in this product category started more than 45 years ago. 2.5 Million cubicles later, SM AirSeT is the latest in this strong heritage. Current breaking technology also spans more than 30 years, a long ffeld experience for our latest designs.

This experience means that today Schneider Electric can propose a complementary range: vacuum type circuit breaker cubicles up to 24 kV and standard or enhanced internal arc withstand cubicles to help reinforce the safety of people according to the IEC standard. This gives you the benefft of unique experience: that of a world leader, with over 2,500 000 Medium Voltage units installed throughout the world.

We have combined this extensive experience with strong focus on customer needs to develop SM AirSeT, a new, green generation of medium voltage switchgear. The modular SM AirSeT is a range of harmonized cubicles with vacuum breaking technology, with a lifespan of 40 years.

These cubicles meet all your Medium Voltage substation requirements up to 24 kV by superposing their various functions. The result of in-depth analysis of your requirements, both now and in the future, SM AirSeT cubicles mean that you can take advantage of all the features of both a modern and proven technology.

Features

Innovation is in the Air

Sustainability, let's clear the Air

Today, everyone wants to decarbonize, but increasing electricity demand creates a conffict of how….. until now!

SM AirSeT answers that need by enabling the change from SF6 to a sustainable technology that combines pure air for insulation and vacuum technology for arc interruption. Our innovative arrangement with Shunt Vacuum Interruption (SVI)™ is used for breaking without use of alernative gases, and producing no toxic by-products.

We offer the same performance, footprint and functionality as our previous generation switchgear, but with the enhanced sustainability available.

Pure air as the ultimate choice

Adopting pure air switchgear is not only better for the environment but also helps improve health and safety as pure air is naturally sustainable. It reduces the switchgear's carbon footprint across its full lifecycle - from manufacturing to end of life - by eliminating the need for SF6 or alternative gas and avoiding the end-oflife recapture, recycling.

No compromise on beneffts

The ingenious design retains the beneffts valued by customers in former SF6 equipment: compact physical footprint, 3-position switch, transformer protection via switch-fuse unit - all important considerations to avoid changes to installations and working practices.

Transparent for the future

Pure air is transparent and gives peace-of-mind, because it helps avoid the risk of future regulations.

Range description

Normal operating conditions

Ambient air temperature

Less than or equal to 40 °C

Less than or equal to 35 °C on average over 24 hours

Greater or equal to -25 °C

Altitude

1 000 m, possible till 3 000 m with impulse withstand voltage and power frequency derating

Solar radiation

No solar radiation inffuence is permitted

Ambient air pollution

No signiffcant pollution by dust, smoke, corrosive and/or ffammable gases, vapors or salt Humidity

Average relative humidity over a 24 hour period, less than or equal to 95 % • Average relative humidity over a 1 month period, less than or equal to 90 %

Average vapor pressure over a 24 hour period, less than or equal to 2.2 kPa

Average vapor pressure over a 1 month period, less than or equal to 1.8 kPa

For these conditions, condensation may occasionally occur. Condensation can be expected where sudden temperature changes occur in periods of high humidity.

To withstand the effects of high humidity and condensation, such as breakdown of insulation, please pay attention to on Civil Engineering recommendations for design of the building or housing, by suitable ventilation and installation.

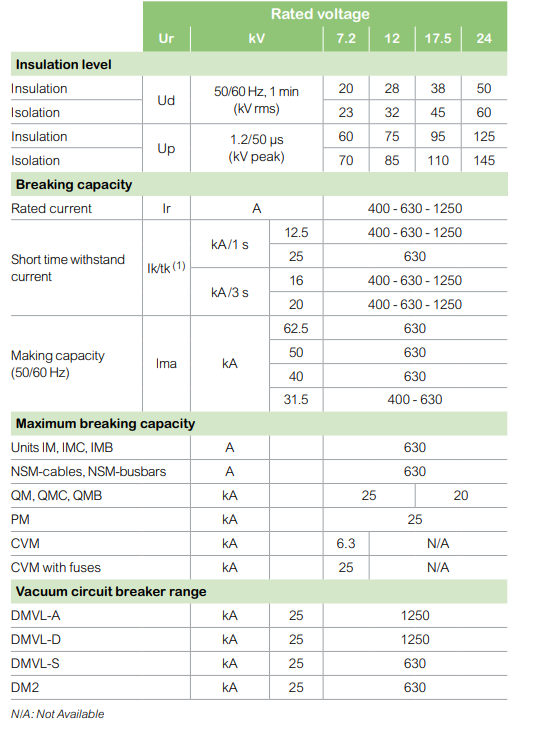

General characteristics

Electrical characteristics

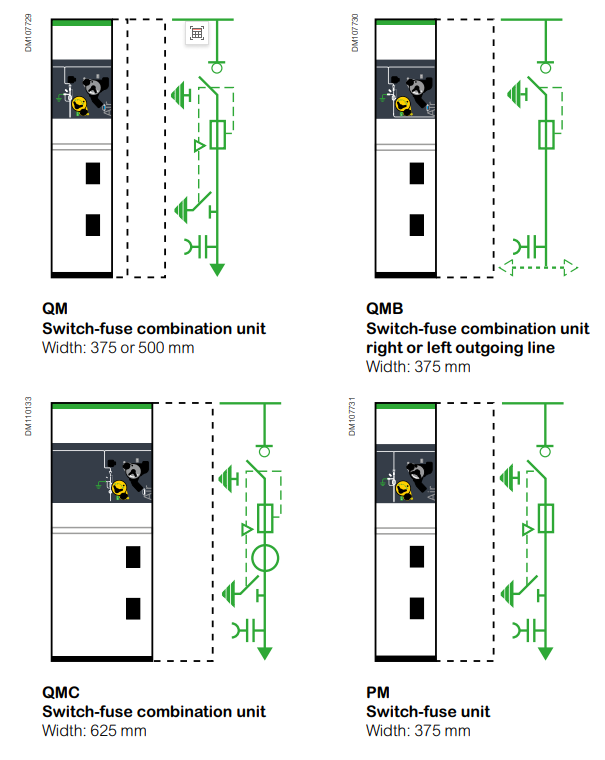

Units for protection function

Switch-fuse

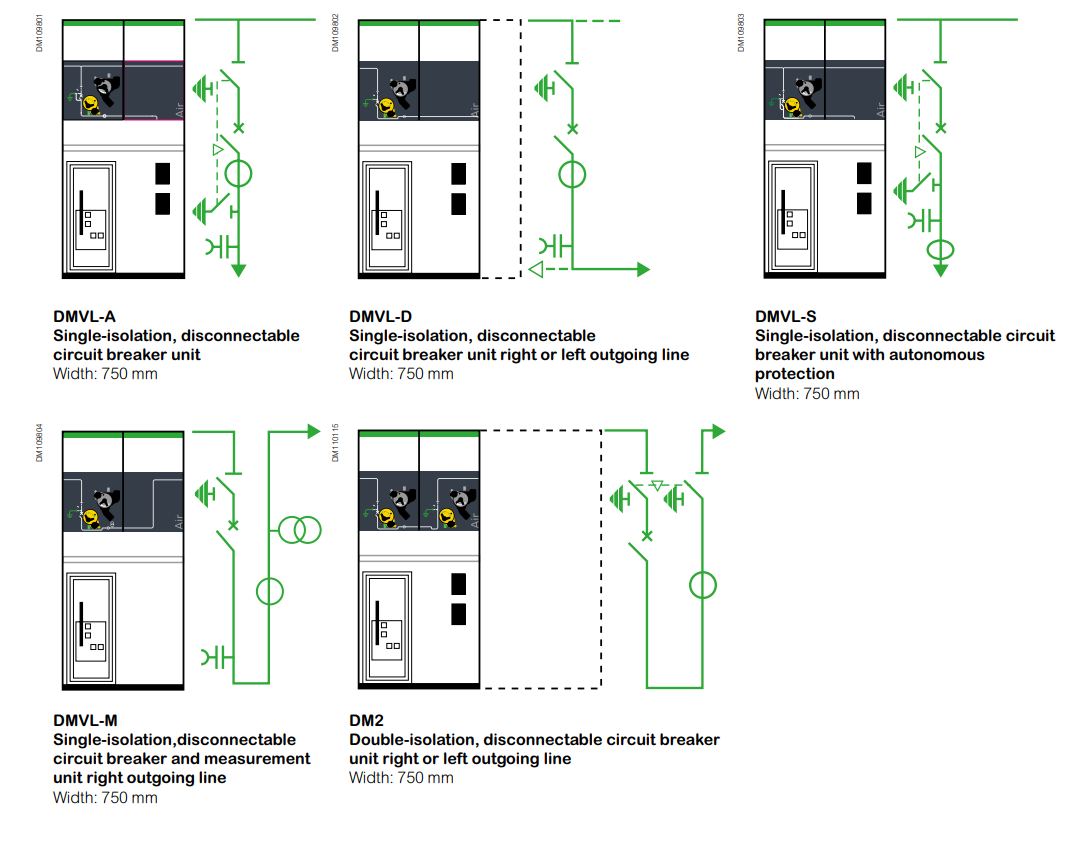

Vacuum circuit-breaker

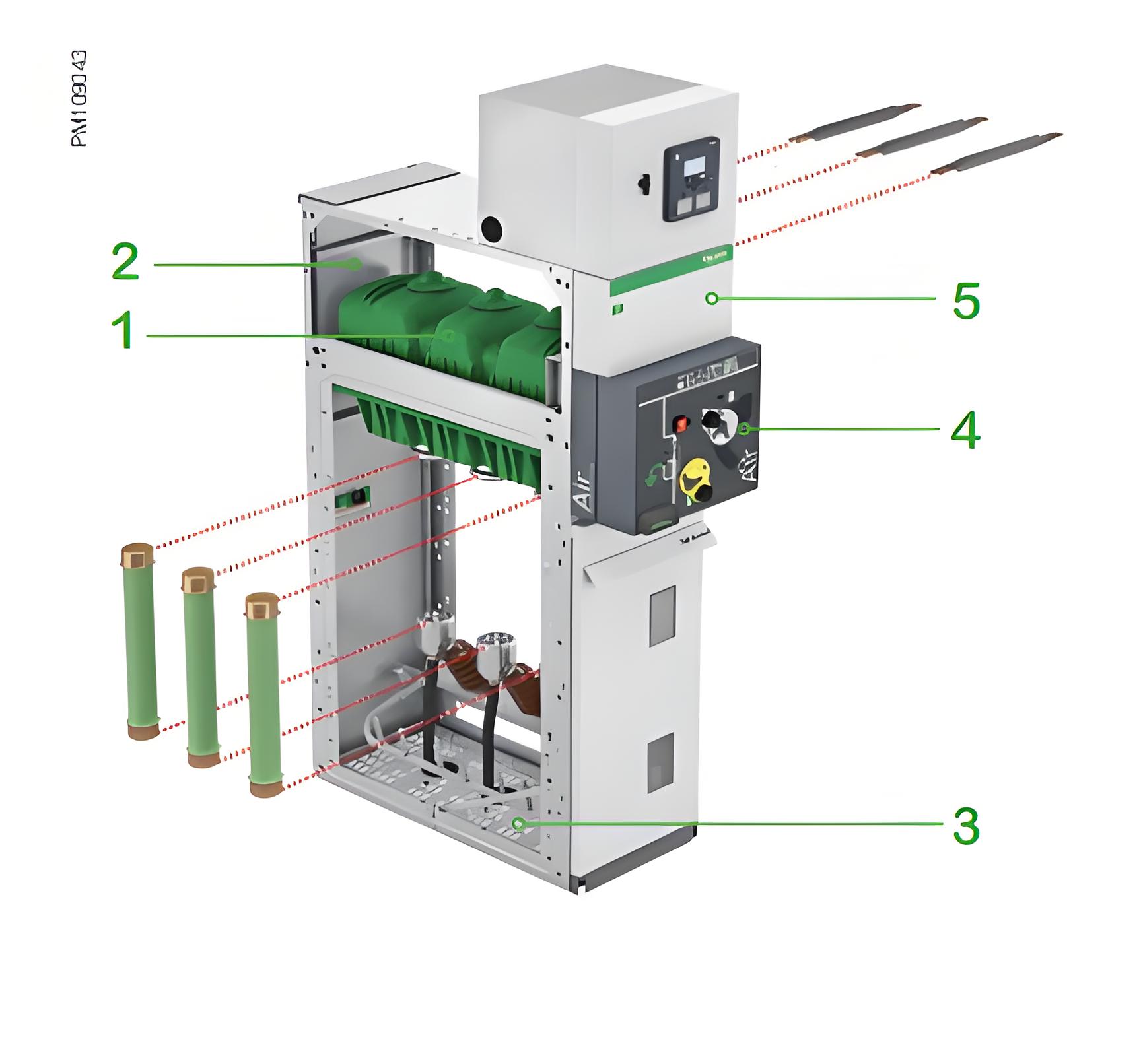

Factory-built cubicles Description

Switch and fuse protection cubicles

1. Switchgear: switch-disconnector and earthing switch in an enclosure fflled with pressurized air, meeting 'sealed pressure system' requirements.

2. Busbars: all in the same horizontal plane, thus enabling later switchboard extensions and connection to existing equipment.

3. Connection: accessible through front, connection to the lower switchdisconnectorand earthing switch terminals (IM cubicles) or the lower fuseholders (PM and QM cubicles). This compartment is also equipped with an earthing switch downstream from the MV fuses for the protection units.

4. Operating mechanism: contains the elements used to operate the switchdisconnectorand earthing switch and actuate the corresponding indications (positive break).

5. Low voltage: installation of a terminal block (if motor option installed), LV fuses and compact relay devices. If more space is required, an additional enclosure may be added on top of the cubicle.

Compartments and devices Switchgear

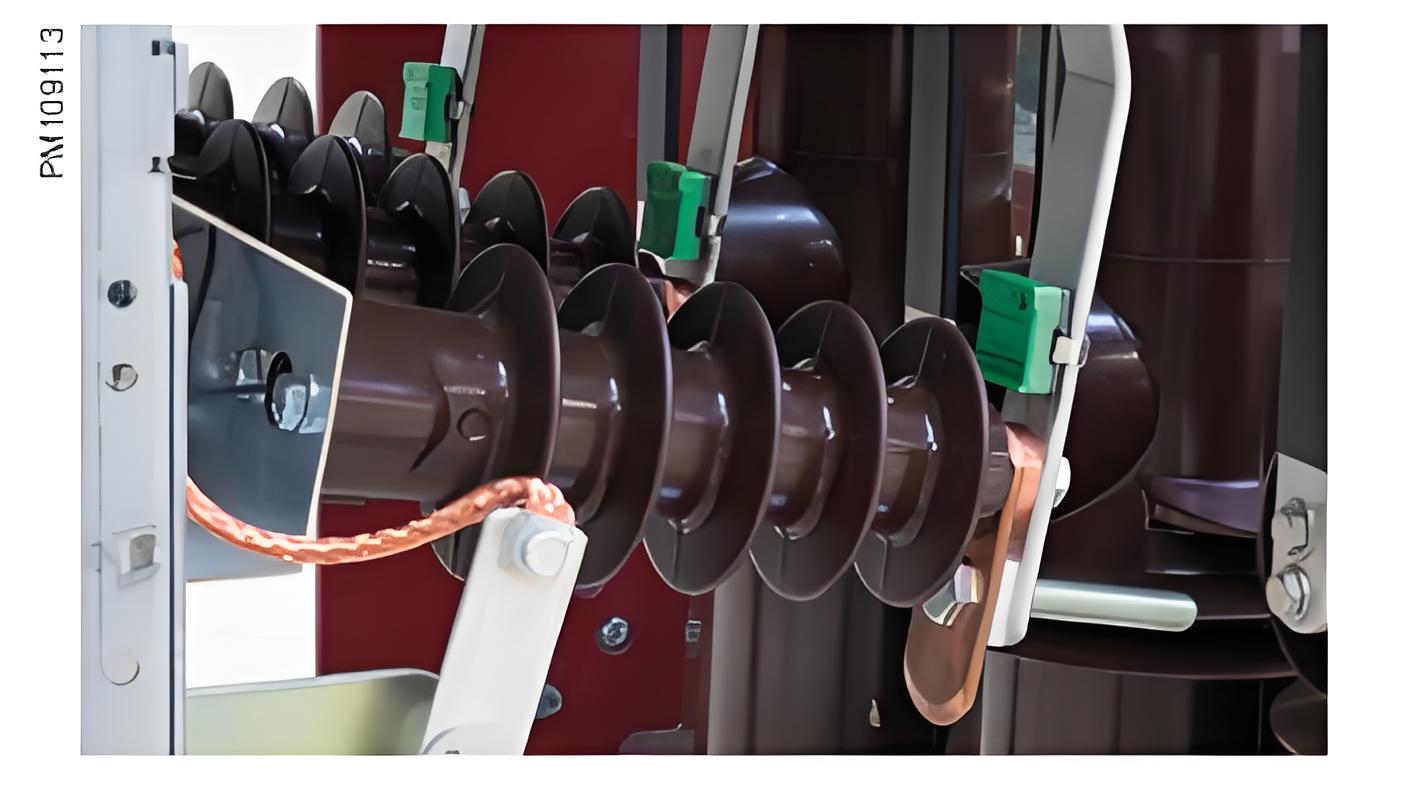

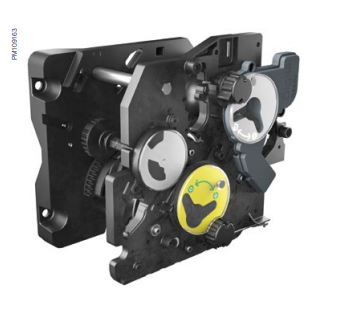

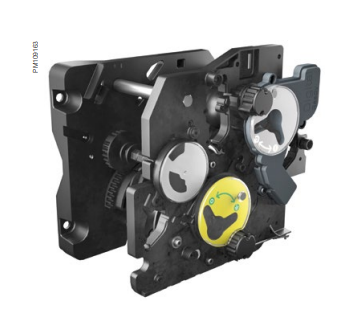

EvoPacT circuit breaker

EvoPacT is our latest range of state-of-the-art vacuum circuit breaker. Its design is the result of more than 40 years of Schneider Electric experience in switching devices. Its wide geographical deployment makes it a key component of SM AirSeT. It has been designed to suit particularly applications such as: MV/LV transformer substations and industrial distribution substations. The materials used to manufacture this circuit breaker have been selected and designed to operate 10 000 cycles.

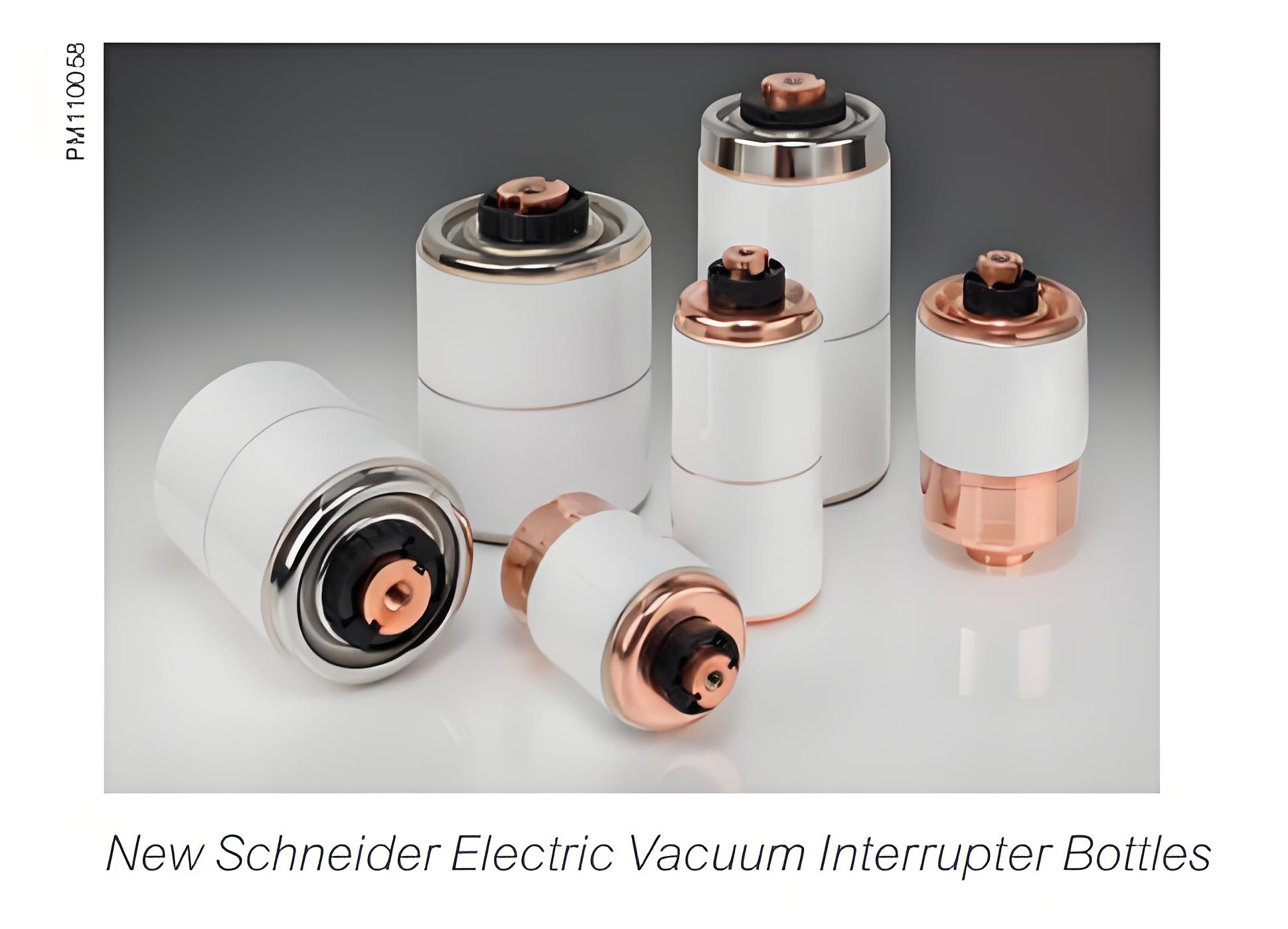

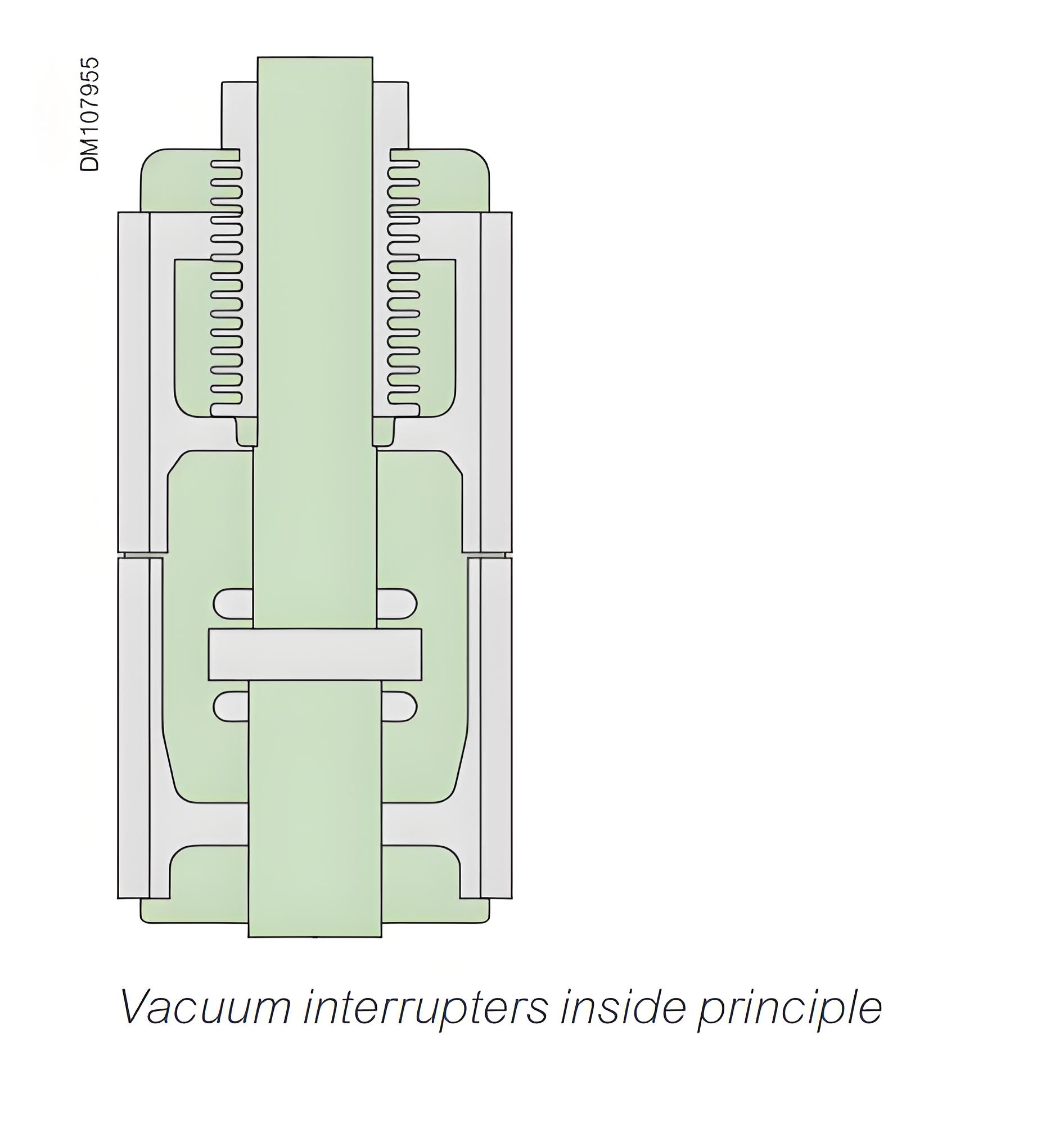

Vacuum interrupter

The heart of the circuit breaker

Vacuum interrupters are the heart of a medium voltage circuit breaker, SF6-free technology: its electrical performances highly depend upon the vacuum interrupter’s characteristics and quality. They must convey and break the rated normal current as well as the rated short circuit one for a number of times speciffed by the manufacturer.

Brand new design

Schneider Electric has been designing and producing its own vacuum interrupters for 45 years and carries a unique know-how in this ffeld. For the EvoPacT circuit breaker, Schneider Electric has designed a brand new range of vacuum Interrupter, following the very robust process of development: "Model based system engineering". Speciffc and innovative solutions have been implemented: the VI shape, the contacts shape, the speciffc barriers to support ceramic protection, the petal shape of the radial magnetic ffeld.

Strict quality controls

The production process includes a total vacuum inside the bottle, high temperature brazing, the use of "getter" material to absorb residual gas and a sealed enclosure. The "anti-twist" feature allows to mount the vacuum interrupter inside the pole of the breaker in an easy way while helping ensure expected performance of the VI. The new range of VI are then fully compliant with all the main breaker standards as GB/T 1984-2014, DL/T 402- 2016, IEC62271-100, IEEE C37.04-1999 and C37.06- 2009.

Operating principle

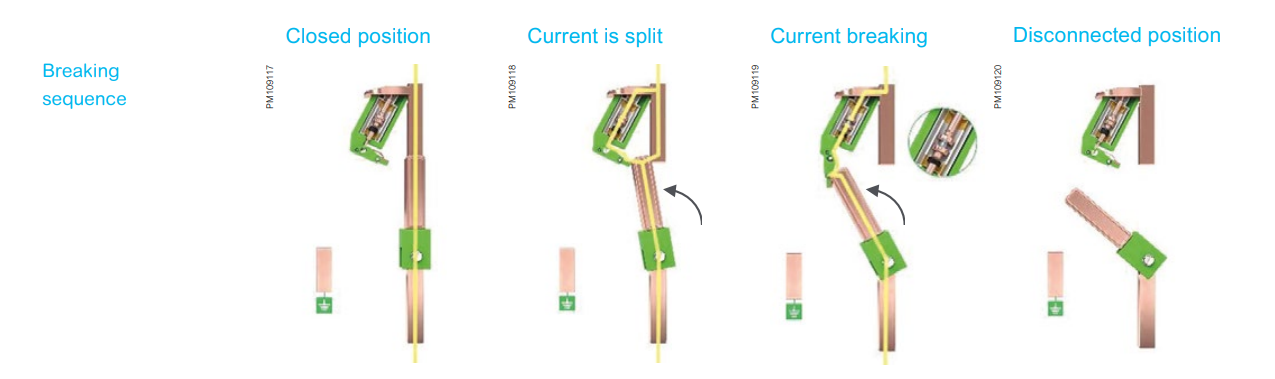

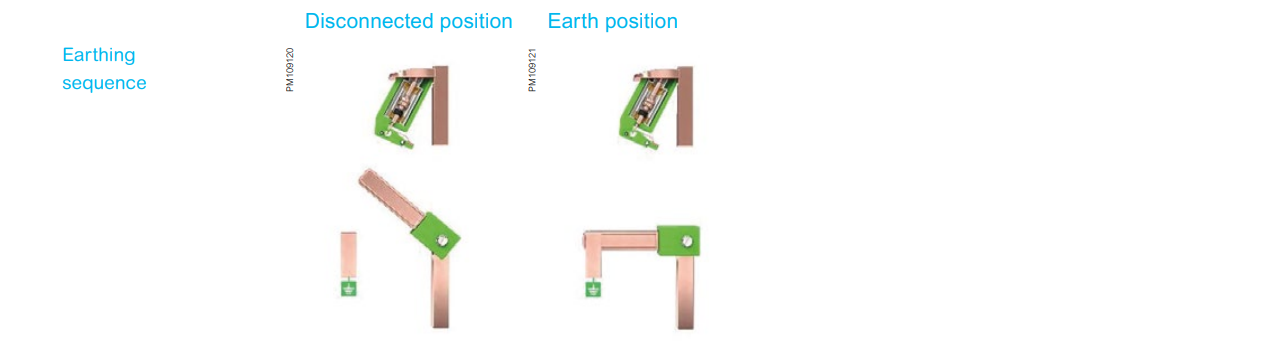

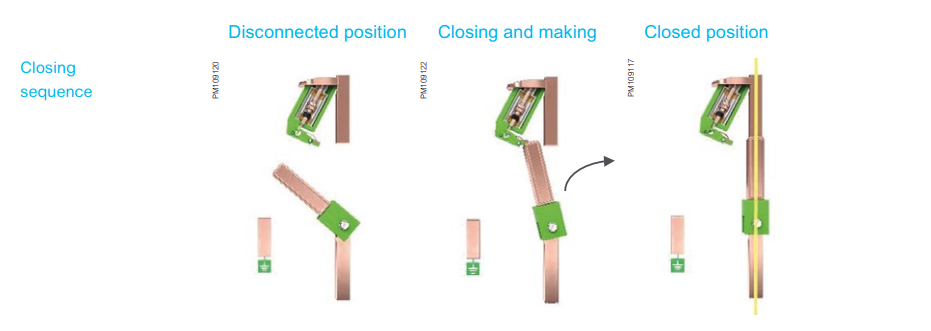

Air and vacuum 3-position switch-disconnector Principle

The principle of the Shunt Vacuum Interruption (SVI) is executed by means of shunting the current through the vacuum interrupter while the disconnector is opening so that the current is interrupted in vacuum.

It is a compact, performing, and tested breaking device for load-break switches and switch-fuse combinations with:

Breaking by vacuum interrupter.

Disconnecting in air gap.

Breaking and disconnecting in one operation as current SF6 3-position switch.

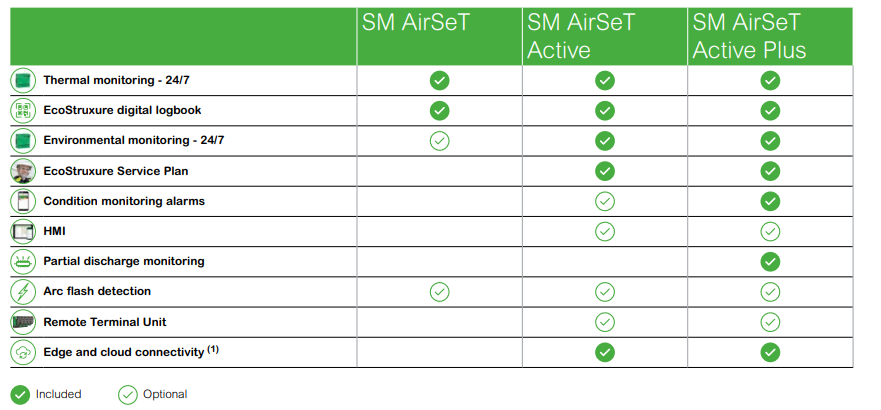

EcoStruxure™ Connected product Offer structure

Connected by default

Digitization provides an opportunity to take real beneffts of data, cloud and analytics with power system equipment. Our latest SM AirSeT equipment offers extensive digital beneffts and connectivity by default in the standard product.

Ready for today and tomorrow, equipment has embedded IoT sensors to provide data to monitor critical components and connections, and the installation environment.

Essential data can be easily shared via on-premises or on-cloud architectures, connected to various applications to help users benefft from data.

Nearby or remote connectivity allows users to monitor or control power system equipment from a safer distance, without even visiting the substation

24/7 data helps maintenance teams greatly improve efffciency and reliability. Respond to problems faster, and be better prepared for site visits.

Not only connected by default, IoT data enables optional digital services, like EcoStruxure Asset Advisor. These services can give you smart alarms or data analytics that help you start your journey to predictive maintenance, efffcient asset management and much more.

Our SM AirSeT is bringing new functionalities and therefore new opportunities. In parallel, our customer needs are diverse and raise different expectations. For this reason, we have introduced 3 scalable tiers of connectivity to better meet your needs.

Edge and cloud connectivity comprise the optional software offers: -EcoStruxure Power SCADA -EcoStuxure Asset Advisor

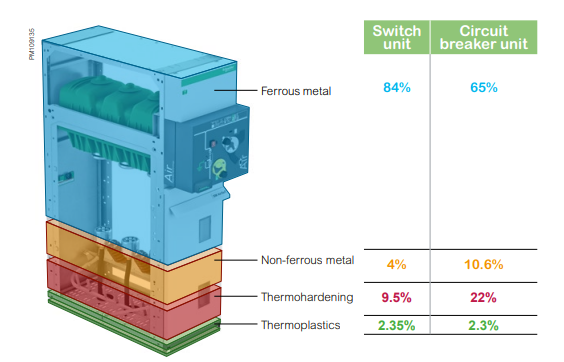

Protecting the environment Schneider Electric is committed to a long term environmental approach.

Environmental performance

All necessary measures have been taken in conjunction with our services, suppliers and subcontractors to help ensure that the materials used in the composition of the equipment do not contain any substances prohibited by regulations and directives.

This has led to the development of SM AirSeT, which contains no SF6 gas and is insulated with air, together with vacuum breaking. This means no concerns about toxic byproducts and end-of-life gas recycling.

It also mean no concerns about any future regulatory bans of SF6 alternative gases. Our Air Insulated Switchgear is designed with environmental protection in mind:

The materials used in, insulators and conductors are identiffed, easily separable and recyclable.

The environmental management system adopted by Schneider Electric’s production sites for the manufacture of our Air Insulated Switchgear has been assessed and recognized as conforming to the requirements of the standard ISO 14001.

Components and accessories

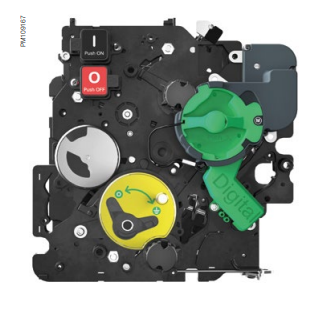

Operating mechanisms

CompoDrive: Adapted to the cases of secondary distribution

SM AirSeT offers three types of CompoDrive operating mechanisms - one per type of application:

Tumbler mechanisms: opening / closing time are independent of the lever speed or the operator

Without latching: CDT

CDTS (applicable for downstream Earth

Switch operation)

With 1 latching systems: CD1

With 2 latching systems: CD2. (Spring with latching allows faster closing and opening for some applications: mostly fuse switches, ATS).

Double-function operating mechanism CDT

Switch function

Operation-independent opening or closing by lever or motor.

Switch and earthing switch functions

Dependent-operation opening and closing by lever.

Earthing switch function

Operation-independent opening or closing by lever.

Operating energy is provided by a compressed spring which, when released, causes the contacts to open or close.

Double-function operating mechanism CDTS

Switch function

Operation-independent opening or closing by lever.

Switch and earthing switch functions

Dependent-operation opening and closing by lever.

Earthing switch function

Operation-independent opening or closing by lever.

Operating energy is provided by a compressed spring which, when released, causes the contacts to open or close.

Operation of downstream earthing switch.

Monitoring & control PS100 high-availability power supply

PS100 backup power supply for MV substations

Applications

The power supply unit supplies backup operating power for:

MV switchgear motor mechanisms and circuit breaker coils

Transmission equipment (e.g. radio)

Control units such as RTU or Automatic Transfer System

Protection relays, Fault Passage Indicators and others electronic devices.

Main features

DIN rail mounting for easy integration in any LV cabinet or MV/LV substation

Two power supply outputs:12 Vdc - 18 W continuous - 100 W 20 s (for modem, radio, RTU, etc.) 48 Vdc or 24 Vdc - 300 W /1 minute (for switchgear operating mechanism motors) and 90 W / continuous for protection relays, electronic devices, etc

RJ45 Modbus communication port

Two output relays (AC supply ON, Battery ON)

Diagnosis with LEDs

One sealed lead-acid 12 V battery with a 10-year service life

(from 7 Ah to 40 Ah)

Power supply paralleling available with a 2nd PS100

- 40 °C to + 70 °C operating temperature.

Beneffts

Only one battery

Traditional backup power supplies require a set of two or four batteries to produce 24 V or 48 V, which complicates replacement and adjustment of the battery pack.

The PS100 needs only one battery, simplifying replacement.

The battery is a standard sealed lead-acid 12 V battery with a 10-year service It can be purchased easily, anywhere in the world.

Improved availability of MV/LV substations

The PS100 is designed to cater for power network interruptions of up to 48 hours. It is associated with a battery selected to meet the required backup time.

The PS100 helps protect and optimizes the battery with state-of-the-art monitoring.

A Modbus communication port forwards monitoring data to allow optimized maintenance operations.

Outstanding integration with the PowerLogic range to control and monitor your distribution network.

Additional energy backup

The PS100 stops supplying power and reserves an 'additional energy backup' to restart the installation after an extended power interruption.

The 'additional energy backup' can be enabled with a local pushbutton to provide energy for restarting the protection relays and operating the MV switchgear.

Withstands severe substation environments

The PS100 includes 10 kV insulation, electronic protection against overvoltage and overloads, and automatic restart after a fault.