Oil Filled Cables

Definition

An oil - filled cable is defined as a cable where low - viscosity oil is maintained under pressure, either within the cable sheath itself or in a containing pipe. Under all conditions of varying loads, the oil in the cable fills the voids in the oil - impregnated paper. Historically, mineral oils were commonly used, but more recently, alkylates such as linear decyl benzene and branched nonyl benzene have gained popularity. This is due to their low viscosity and their ability to absorb water vapors released during the ageing of cellulose.

Oil - filled cables are utilized for long - distance power transmission or in locations where aerial cables are impractical, such as underwater (e.g., in seas), in underground hydroelectric plants, or in power substations with water obstacles.

Advantages of Oil - Filled Cables

The pressure within the cable is sustained by connecting the oil channel of the cable to an oil tank. To maintain the pressure, the oil channel is positioned at a distance from the oil reservoir. The oil pressure mitigates the formation of voids in the insulator. Compared to solid cables, oil - filled cables offer the following advantages:

- They can withstand greater operating dielectric stress.

- They have a higher working temperature and a greater current - carrying capacity.

- Their impregnation quality is superior to that of solid cables.

- Impregnation can be carried out even after the sheathing process.

- Void formation is eliminated.

- Their size is smaller than that of solid - filled cables because of their thinner dielectric layer.

- Defects can be easily detected through oil leakage.

Types of Oil - Filled Cables

Oil - filled cables are primarily categorized into three types:

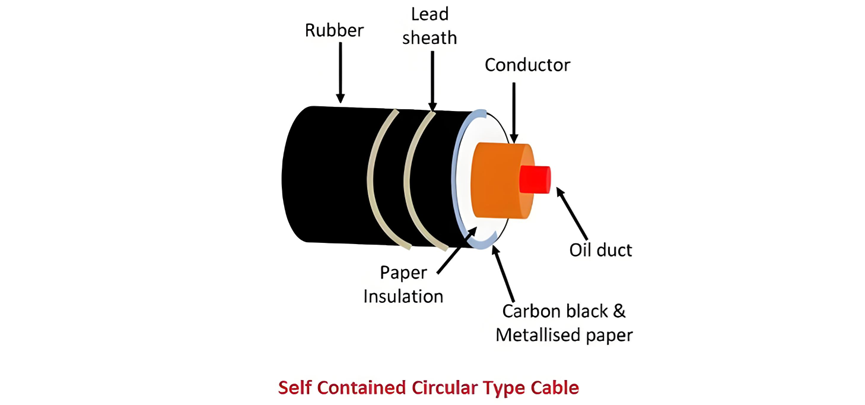

- Self - contained Circular Type Oil Cable

- Self - contained Flat Type Cable

- Pipeline Cable

- Self-Contained Oil-filled Cable

For self - contained oil - filled cables, the cross - sectional area of the conductor is approximately 150 - 180 square millimeters and is made of tin. The diameter of the oil ducts in such cables is around 12 mm. This type of cable is predominantly used for voltages up to 110 - 220 kV.

Advantages of Self - contained Oil - filled Cables

Compared to other oil - filled cables, self - contained oil - filled cables offer the following benefits:

- The presence of oil ducts allows for a smaller conductor size.

- Installation is straightforward.

- Costs are lower.

- Instead of pumps, only oil tanks are needed for operation.

- Due to these advantages, self - contained oil - filled cables are widely utilized.

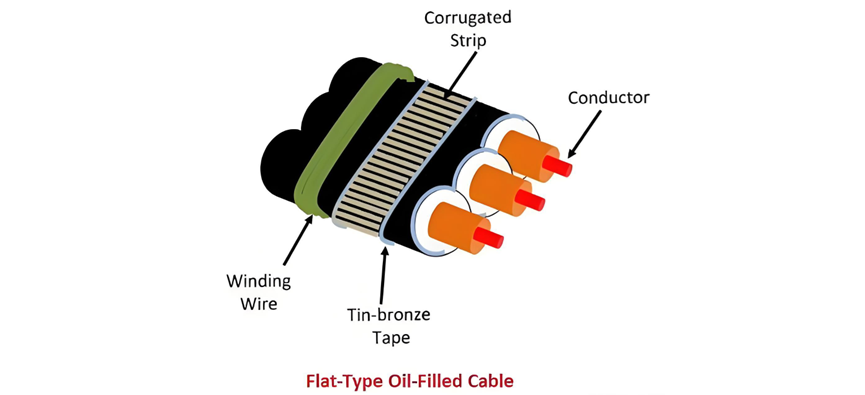

Flat Type Oil - Filled Cable

In flat type oil - filled cables, three insulated cores are arranged horizontally side by side. There is no filter material; instead, the space is filled with oil under pressure. The flat sides of the lead sheath are reinforced with hard metallic tapes or bands and winding wires. The supporting bands are fluted to enhance the cable's flexibility.

When the cable is loaded, its temperature increases, causing the oil to expand and slightly deform the flat sides of the sheath. As the load decreases, the oil contracts, and the resilient bands reduce the deflections. This minimizes the formation of voids in the dielectric during cooling.

These cables feature oil ducts that are fully filled with oil. The oil is kept under pressure, with a strength of 180 kV/cm. In this type of cable, all the free space between the cores is available for oil flow. The oil fills the free spaces within the insulation, thereby enhancing the insulation's strength.

Oil storage tanks are positioned at appropriate intervals along the cable route to accommodate thermal expansion and contraction. When the cable is loaded, heat is generated, causing the oil to be pushed from the cable into the oil storage tanks. Conversely, when the load decreases, the oil moves back into the cable. This mechanism effectively prevents the formation of voids.

Pipe - Type Oil - Filled Cables

A pipe - type oil - filled cable comprises three individual paper - insulated screen cores that are installed inside a steel pipe. The pipe is filled with insulation oil maintained at a pressure ranging from 1.38×10⁶ to 1.725×10⁶ N/m². The high - pressure oil serves a dual purpose: it inhibits the formation of voids and helps in dissipating heat from the cable. Notably, in this type of cable, a conductor oil duct is not necessary.