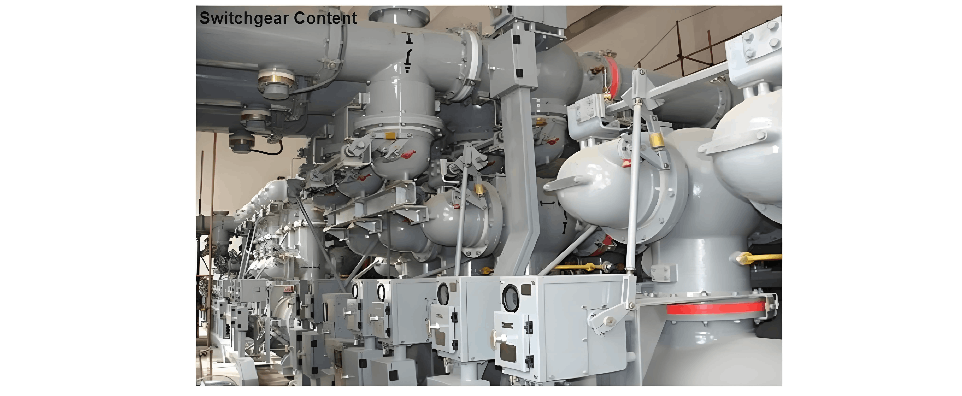

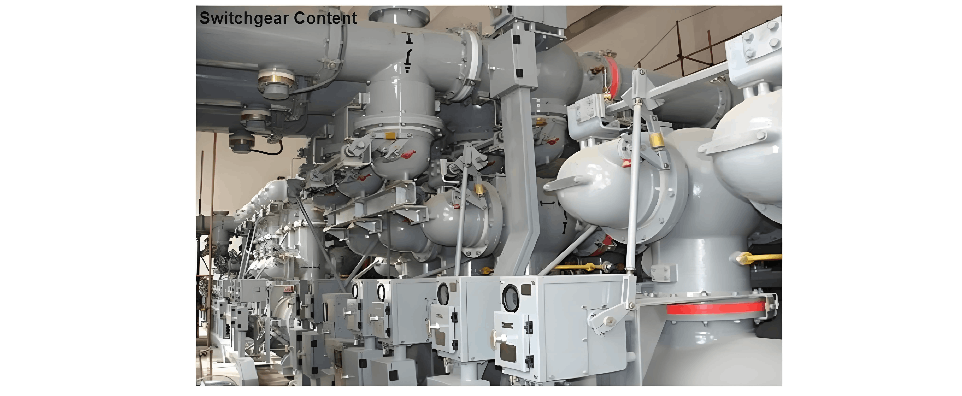

This inspection of GIS components can typically be carried out every 5 - 10 years. However, its frequency can also hinge on the number of operations of switching devices and the manufacturer's recommendations. The overarching aim is to verify the proper functioning of all switching devices. To this end, the relevant equipment must be de - energized.

GIS manufacturers furnish users with recommended maintenance plans, which should be scrupulously adhered to. The typical operations during this inspection are as follows:

- Check the SF6 pressures (density).

- Examine the operations of SF6 density relays, including wiring and alarms.

- Verify the purity of SF6 gas.

- Assess the content of SF6 by - products and impurities (such as SO2 and moisture, in compartments lacking absorbers).

- Detect any SF6 leakages (especially in the event of alarms since the last inspection).

- Record and review the operating times of circuit breakers (using auxiliary switches).

- Operate the circuit breakers and switching devices.

- Check the correct operation of pressure switches, applicable when hydraulic mechanisms are in use.

- Inspect the proper alignment and operation of position indicators.

- Verify the control and alarm functions.