Air Blast Circuit Breaker

Air Blast Circuit Breakers: Operation, Advantages, and Types

An air blast circuit breaker utilizes compressed air or gas as the arc - interrupting medium. Compressed air is stored in a tank and, when needed, released through a nozzle to generate a high - velocity jet. This jet plays a crucial role in extinguishing the arc that forms when the circuit breaker interrupts the electrical current.

Air blast circuit breakers are commonly employed for indoor applications in the medium - high voltage range with medium rupturing capacities. Typically, they are suitable for voltages up to 15 kV and rupturing capacities of 2500 MVA. Additionally, they are now used in high - voltage outdoor switchyards for 220 kV lines.

While various gases such as carbon dioxide, nitrogen, freon, or hydrogen can potentially serve as arc - interrupting media, compressed air has emerged as the preferred choice for gas blast circuit breakers. There are several compelling reasons for this:

Nitrogen: Its circuit - breaking capabilities are comparable to those of compressed air, offering no significant advantage in terms of performance.

Carbon Dioxide: One of its major drawbacks is the difficulty in controlling its flow. It has a tendency to freeze at valves and other narrow passages, which can disrupt the proper functioning of the circuit breaker.

Freon: Although it boasts high dielectric strength and excellent arc - extinguishing properties, it comes with a hefty price tag. Moreover, when exposed to an arc, it disintegrates into acid - forming elements, posing risks to the equipment and the surrounding environment.

Air blast circuit breakers offer several desirable features:

High - Speed Operation: In large interconnected electrical networks, maintaining system stability is of utmost importance. Air blast circuit breakers excel in this regard due to the extremely short time interval between the discharge of the triggering impulse and the separation of the contacts. This rapid response helps minimize the impact of faults on the overall electrical grid.

Suitability for Frequent Operation: Unlike circuit breakers that use oil, which can rapidly carbonize and degrade with repeated switching, air blast circuit breakers can withstand frequent operation. The absence of oil also means that there is minimal wear and tear on the current - carrying contact surfaces. However, it is essential to ensure a continuous and sufficient supply of compressed air when frequent switching is expected.

Negligible Maintenance: The ability to handle repeated switching with ease translates into reduced maintenance requirements. This not only saves on maintenance costs but also enhances the reliability and availability of the circuit breaker.

Elimination of Fire Hazard: Since air blast circuit breakers do not contain oil, the risk of fire associated with oil - filled circuit breakers is completely eliminated, making them a safer option for electrical installations.

Reduced Size: The rapid growth of dielectric strength in air blast circuit breakers allows for a much smaller final gap required for arc extinction. This compact design results in smaller - sized devices, which can be more easily integrated into electrical systems and occupy less space.

Principle of Arc Extinction

An air blast circuit breaker relies on an additional compressed air system to supply air to the air receiver. When the circuit breaker needs to open, compressed air is directed into the arc extinction chamber. This high - pressure air exerts a force on the moving contacts, causing them to separate. As the contacts pull apart, the air blast sweeps away the ionized gas formed by the arc, effectively extinguishing it.

The arc is typically extinguished within one or more cycles. After arc extinction, the arc chamber is filled with high - pressure air, which helps prevent restrikes. Air blast circuit breakers fall under the category of external extinguishing energy type. The energy used for quenching the arc is derived from the high - pressure air, independent of the current being interrupted.

Types of Air Blast Circuit Breakers

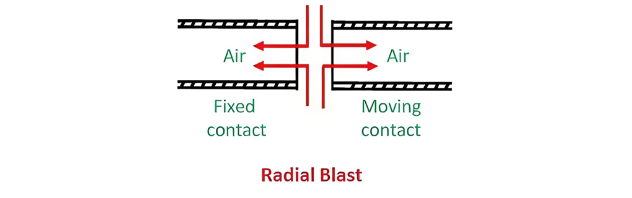

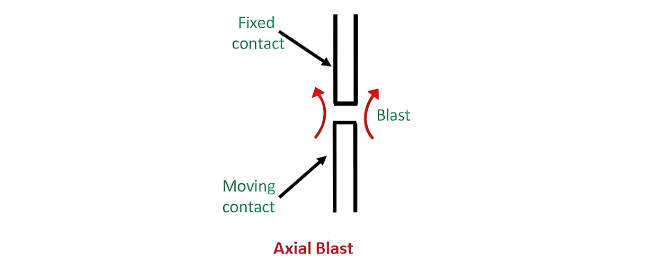

All air blast circuit breakers operate on the principle of separating their contacts in an arc - forming airflow created by opening a blast valve. The arc that forms is quickly centered through a nozzle, where it is maintained at a fixed length and subjected to the maximum force of the air flow. Based on the direction of the compressed air blast around the contacts, air blast circuit breakers can be classified into three types:

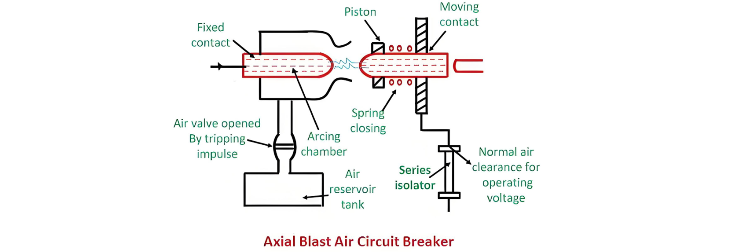

Axial Blast Air Circuit Breaker: In this type, the air flow is parallel to the arc, flowing longitudinally along its length. Axial blast air circuit breakers can be further categorized as single - blast or double - blast. Some double - blast arrangements, where the air blast flows radially into the nozzle or the space between the contacts, are sometimes referred to as radial blast circuit breakers, despite the primary axial - flow design concept.

The fundamental structure and operation of an air blast circuit breaker are illustrated in the diagram above. Under normal operating conditions, the fixed and moving contacts remain in a closed state, held together by the force exerted by springs. An air reservoir tank is linked to the arc chamber via an air valve. This valve is activated by a triple impulse mechanism, which triggers its opening when a fault or the need to interrupt the current arises.

When a fault occurs in the electrical system, the tripping impulse serves as the catalyst for action. This impulse activates the air valve that connects the air reservoir to the arcing chamber, causing it to open. As high - pressure air from the reservoir rushes into the arc chamber, it exerts a significant force on the moving contacts. Once the air pressure surpasses the resistance provided by the spring force that normally holds the contacts closed, the moving contacts begin to separate, initiating the process of interrupting the electrical current and extinguishing the arc.

When the contacts separate due to the pressure of the high - velocity air, an arc forms between them. The air, flowing at a high speed axially along the length of the arc, effectively removes heat from the arc's periphery. As the current approaches zero, this continuous heat extraction causes the arc's diameter to shrink significantly. At the moment when the current reaches zero, the arc is successfully interrupted. Subsequently, fresh air, streaming through the nozzle, fills the space between the contacts. This flow of fresh air clears away the hot, ionized gases that were present in the contact space, rapidly restoring the dielectric strength between the contacts and preventing any potential re - ignition of the arc.

Cross Blast Air Circuit Breaker

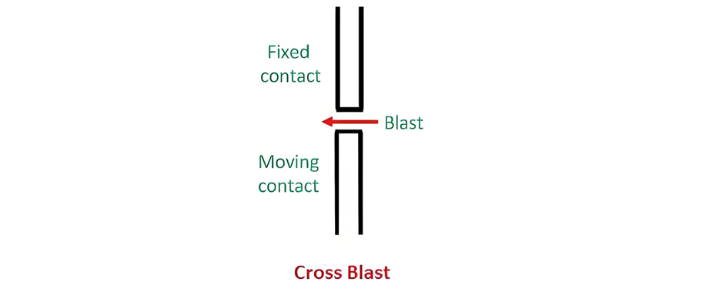

In a cross blast air circuit breaker, the arc - extinguishing mechanism operates differently. Here, the arc blast is directed perpendicular to the arc itself. The figure below provides a schematic illustration of the cross blast principle employed in this type of circuit breaker. When the moving contact arm is actuated within a confined space, an arc is generated. Immediately, a transverse blast of air propels this arc towards the splitter plates. The splitter plates fragment the arc into smaller segments, dissipating its energy. This process effectively weakens the arc to the extent that, after the current passes through zero, it lacks the energy to restrike, ensuring the successful interruption of the electrical circuit.

Resistance Switching and Drawbacks of Air Blast Circuit Breakers

Resistance Switching

Typically, resistance switching isn't an absolute necessity in air blast circuit breakers. When the arc is quenched, it inherently creates some resistance, which helps to regulate the transient restriking voltage. However, if additional resistance is deemed beneficial for specific applications, it can be incorporated by connecting a resistor across the arc splitter section. This added resistance provides an extra layer of control over the voltage transient, enhancing the circuit breaker's performance under certain conditions.

Drawbacks of Air Blast Circuit Breakers

One of the major limitations of air blast circuit breakers is the strict requirement for a continuous supply of compressed air at the precise pressure. To ensure this availability, large - scale installations are often needed, typically featuring two or more compressors. Maintaining this complex compression plant is no small task; it demands regular upkeep to keep the compressors running efficiently and to address any mechanical issues that may arise.

Moreover, air leakage at pipe fittings is a persistent problem. Even minor leaks can gradually deplete the air pressure, compromising the circuit breaker's performance. Detecting and rectifying these leaks can be time - consuming and labor - intensive. These maintenance challenges, combined with the need for a sophisticated air supply system, contribute to higher operational costs.

When compared to oil or other types of air - break circuit breakers, air blast circuit breakers are particularly expensive for low - voltage applications. The extensive infrastructure required for compressed air generation and the associated maintenance expenses make them less cost - effective in scenarios where lower voltages are involved, limiting their widespread use in such contexts.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.