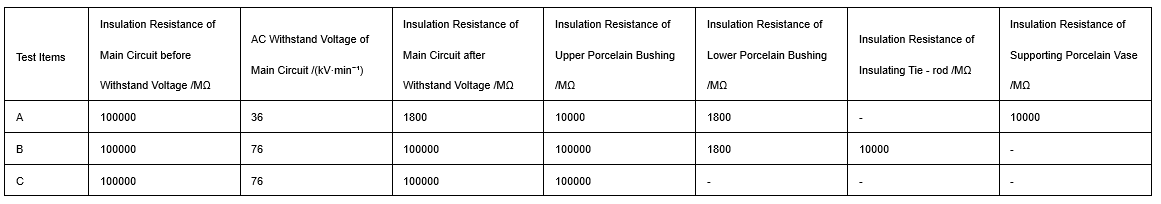

According to the routine test regulations of the State Grid Corporation, the insulation resistance of vacuum circuit breakers at 35 kV and above should not be lower than 3000 MΩ, and the AC withstand voltage test voltage should be 80% of the factory - tested value, that is, 76 kV/min. Before the testing personnel conducted the withstand voltage test on the 3515 vacuum circuit breaker, the insulation resistance of the main circuit in all three phases met the requirements of the regulations.

Subsequently, the testing personnel conducted AC withstand voltage tests on the main circuits of the three phases respectively. It was found that when the voltage of phase A's main circuit rose to 35 kV, the current increased instantaneously and a breakdown occurred.

After this phenomenon occurred, the testing personnel carried out the following tests based on the structure of this type of circuit breaker:

- The vacuum circuit breaker was opened, and an insulation resistance test was carried out on the upper porcelain bushing of the circuit breaker. The test data met the requirements of the regulations, confirming that the defective part was in the lower porcelain bushing.

- An insulation resistance test was carried out on the lower porcelain bushing. The test data did not meet the requirements of the regulations, further confirming that the defective part was in the lower porcelain bushing.

- The lower porcelain bushing consisted of the lower porcelain bushing body, the insulating tie - rod, and the supporting porcelain vase. Therefore, the testing personnel disconnected the crank arm between the insulating tie - rod and the supporting porcelain vase, and carried out insulation resistance tests on the insulating tie - rod and the supporting porcelain vase respectively. The insulation resistances of both the supporting porcelain vase and the insulating tie - rod met the requirements of the regulations, determining that the defective part was in the lower porcelain bushing body.

- The lower porcelain bushing body included vacuum insulating grease and current transformers. The decrease in insulation resistance might be caused by the dampness of the vacuum insulating grease and the breakdown of the current transformers.

At the end of October 2010, the manufacturer disassembled and inspected the phase A circuit breaker. The test steps and results were as follows:

- The upper porcelain bushing and the support of the vacuum circuit breaker were removed, and an insulation resistance test was directly carried out inside the supporting porcelain vase. The test results verified that the above - mentioned analysis was accurate.

- The vacuum insulating grease and the current transformers of the vacuum circuit breaker were separated, and insulation resistance tests were carried out on them respectively. The insulation resistance of the vacuum insulating grease was about 50 MΩ, while the insulation resistance of the current transformers met the requirements of the regulations. It was determined that the insulation breakdown was caused by the vacuum insulating grease.

- After replacing the vacuum insulating grease, insulation resistance and AC withstand voltage tests were carried out on phase A of the vacuum circuit breaker. The test data all met the requirements of the regulations.

The external insulation of the ZW7 - 40.5 type vacuum circuit breaker uses vacuum insulating grease, which is a liquid insulating medium. During the operation and installation of the equipment, the moisture content of the liquid medium will increase. The moisture is in a suspended state in the insulating grease of the electrical equipment. Under the action of the electric field force, the water will gradually arrange itself into a "bridge" along the electric lines of force.

This "bridge" runs through the two poles and is likely to significantly reduce the breakdown voltage. This also explains why the insulation resistance was quite low under a 5 kV voltage during the telemetry of insulation resistance, but this hidden danger was not exposed under the operating voltage.

Through the above - mentioned analysis, in order to avoid the fault of insulation breakdown caused by the dampness of the vacuum insulating grease of the vacuum circuit breaker, the following preventive measures are proposed: