The ZW32 - 12 vacuum circuit breaker is widely used in the power distribution network. However, the performance of ZW32 - 12 vacuum circuit breakers produced by different manufacturers varies. Some ZW32 - 12 vacuum circuit breakers have relatively low overall performance, with potential operation failures that may lead to power outages in some areas [1]. The outdoor ZW32 - 12 type vacuum circuit breaker has superior performance, long electrical and mechanical service life, and is miniaturized and lightweight.

But in actual operation, it may also encounter operation problems due to leakage, short - circuit, or overload. Only by continuously summarizing operation experience and adopting scientific and effective preventive measures can the operation failures of ZW32 - 12 vacuum circuit breakers be reduced or avoided. Scientific analysis of common faults of ZW32 - 12 vacuum circuit breakers and taking certain preventive measures are effective ways to reduce the operation failures of vacuum circuit breakers.

The day of the accident was a thunderstorm. During operation, it was found that phase B of the faulty switch lost ground, causing the faulty circuit breaker to trip, and all users at the rear end of the faulty switch experienced a short - term power outage. At that time, only emergency measures could be taken, that is, tripping the vacuum circuit breaker at the previous level of the faulty circuit breaker, disconnecting all the wiring on the power supply side and load side of the faulty circuit breaker, and bridging a bypass switch across both ends of the faulty circuit breaker, thus restoring the normal power supply of the entire line in a short time.

The faulty switch was removed from the pole. It was found that the insulation resistance to ground for both closing and opening of phase B on the load side of the faulty switch was zero, while the insulation resistance to ground of the power supply side was non - zero when opening (after removing the incoming and outgoing lines of the circuit breaker, each phase was tested with a megger). Based on the described phenomena, it can be considered that there was a grounding phenomenon in the phase B line on the load side of the switch, and the power supply side line of phase B was normal. This fault was related to the grounding of the load - side line.

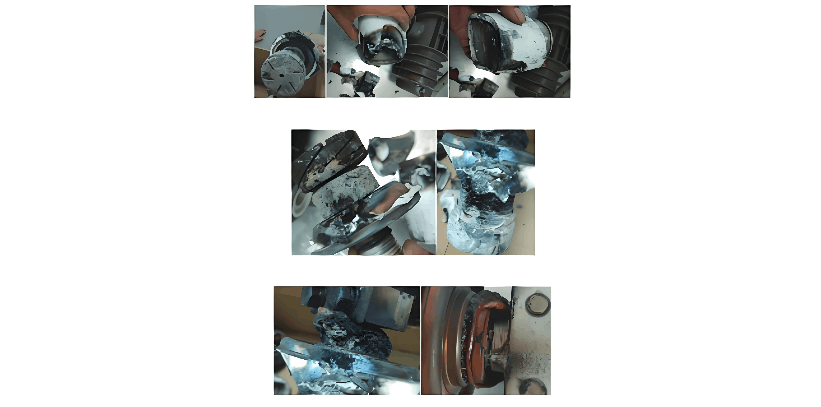

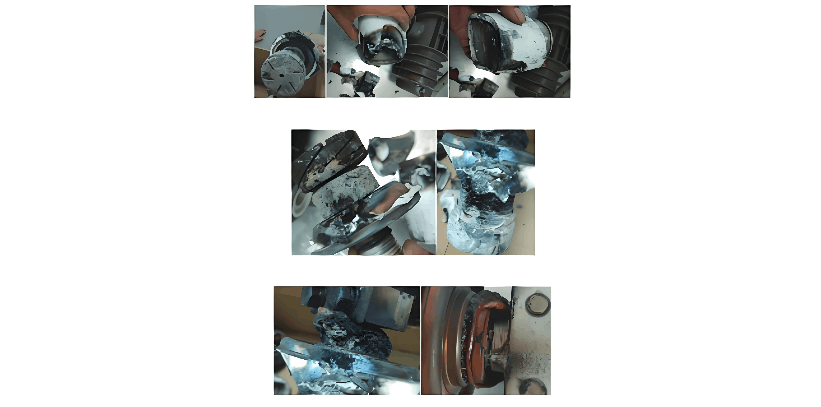

Through disassembling and inspecting the switch, it was found that the outer part of the arc - extinguishing chamber of the phase B insulating cylinder had a discoloration phenomenon. After disassembling the phase B insulating support, it was found that the arc - extinguishing chamber was burned out. The conditions of the disassembled parts of the arc - extinguishing chamber are as follows: the moving and stationary contacts of the arc - extinguishing chamber were intact, with no obvious burn marks on the surface, but the surface was black and had a relatively thick deposit of soot. There was one burn mark at each end of the shielding cylinder, with a relative position difference of about 180° in the circumferential direction.

There were burn marks at the stationary - end grading shield corresponding to the burn mark position at the stationary end of the shielding cylinder, and burn marks at the moving - end bellows and bellows protection cover corresponding to the burn mark position at the moving end. The ceramic shell was burned at the corresponding positions of these two burn marks. The inner wall of the shielding cylinder was black, and the outer wall away from the burn marks was normal in color. There were no abnormal marks on the outer surface of the remaining ceramic shell. The guide sleeve softened and flowed downward. The flowing was severe at the part corresponding to the burn mark at the moving end, and there was an approximate boiling phenomenon. The solidified guide sleeve fixed the moving conductive rod in the open position.

Judging from the surface state of the moving and stationary contacts of the arc - extinguishing chamber, it shows that the contacts did not experience arc burning in an atmospheric environment, and the contacts should be in an open state; the inner wall surface of the shielding cylinder is black, which is formed by the action of the arc and a small amount of air. The outer side of the shielding cylinder away from the burn marks has no discoloration because it is not affected by the arc, indicating that the arc is a local ablation; the gaps on both sides between the stationary - end grading ring of the arc - extinguishing chamber and the stationary end of the shielding cylinder are severely burned, indicating that arc burning occurred there; the gaps on both sides between the moving end of the shielding cylinder and the protection cover behind the moving - end contact of the arc - extinguishing chamber are severely burned, indicating that arc burning occurred there.

The guide sleeve has melting and flowing marks, and the flowing is severe and has a boiling phenomenon at the same position as the burn mark at the moving end, indicating that the high temperature of the arc had a great impact on this area and lasted for a certain period; the solidified guide sleeve fixed the moving conductive rod in the open position, indicating that the switch performed an opening operation during the fault and that the switch was in the open state after the fault; the contact surface has a soot deposit, indicating that its temperature was low during the arc duration and there was no arc burning on its surface in the later stage of the accident development. It also shows that the switch was in the open state in the later stage of the fault. The accident process should be as follows:

Before the fault occurred, the vacuum interrupter had leaked air for some reason. Although there was still a certain degree of vacuum, it no longer met the operating conditions of the vacuum interrupter. When the accident occurred, the circuit breaker was in the closing operating state, and the contacts of the interrupter were closed. When the phase B line on the load side of the switch was grounded, the switch tripped automatically.

The interrupters of phases A and C were in good condition and successfully completed the breaking operation. The phase B interrupter, with a vacuum degree that did not meet the operating conditions, still managed to extinguish the arc between the contacts successfully because in a three - phase neutral - ungrounded system, when two phases are broken, the third phase must also be broken.

This also confirms that the contact surface was intact, with no obvious ablation even at the edges and corners. The arc combustion was not completely confined between the two contacts and had a certain degree of diffusion, resulting in the blackening of the inner wall of the shielding cylinder.Since the inside of the interrupter was in a low - vacuum state, the vacuum insulation ability was extremely low. This led to the breakdown and arcing between the shielding cylinder and the moving - end bellows protection cover under the recovery voltage, and the arc could not be controlled.

The shielding cylinder heated up severely, and its potential changed, causing a breakdown (breakdown at the weakest point) with the stationary - end shielding cover and generating an arc. The arc transferred from the moving end to the stationary end, forming a current path from the power supply to the ground and sustaining the arc combustion until the upper - level switch of this switch tripped and the arc extinguished.There was still a certain degree of vacuum in the vacuum interrupter, but it no longer met the operating conditions due to gas leakage for some reason before the fault occurred.

When the accident happened, the circuit breaker was in the closed - circuit operating state, with the contacts of the interrupter closed. When the phase B line on the load side of the switch was grounded, the switch tripped automatically. The interrupters of phases A and C were in good condition and successfully completed the breaking operation.For the phase B interrupter, although the vacuum degree did not meet the operating conditions, the arc between the contacts was still successfully extinguished.

This is because in a three - phase neutral - ungrounded system, when two phases are broken, the third phase will inevitably be broken as well. This also confirms that the contact surface was intact, with no obvious ablation even at the edges and corners. The arc combustion was not completely confined between the two contacts and spread to some extent, causing the inner wall of the shielding cylinder to turn black.As the interior of the interrupter was in a low - vacuum state, its vacuum insulation capacity was extremely low. This led to breakdown and arcing between the shielding cylinder and the moving - end bellows protection cover under the recovery voltage, and the arc could not be controlled.

The shielding cylinder heated up severely, and its potential changed, resulting in breakdown (at the weakest point) with the stationary - end shielding cover and generating an arc. The arc transferred from the moving end to the stationary end, forming a current path from the power source to the ground and sustaining the arc combustion until the upstream switch of this switch tripped and the arc was extinguished.