Outdoor vacuum circuit breakers are predominantly utilized in the Medium High Voltage (MHV) segment. They serve as a crucial component in the distribution sector, especially within 11kV and 33kV grids. A variety of composite materials are employed in the construction of these breakers. Among them, the vacuum interrupter stands out as the most vital component. For outdoor circuit breakers, the vacuum interrupter is typically encased in a porcelain housing.

These breakers are connected to the operating mechanism via fibreglass - reinforced resin - cast operating rods, which are, in turn, linked to a common gang operating rod made of metal - steel. The operating mechanism of outdoor vacuum circuit breakers generally adopts a spring - type design, housed within a sheet steel enclosure. Given the use of multiple materials, it is essential to assess the compatibility of these materials, as well as the design and workmanship, under diverse environmental conditions where the breakers are intended to operate. This evaluation ensures trouble - free performance and, consequently, the stability of the electrical network they are part of.

Environmental tests for circuit breakers, specifically low - temperature and high - temperature tests, are covered under clause 6.101.3 of IEC 62271 - 100[1]. For cold - volt climates, the preferred temperature range for minimum and maximum values is - 50°C to + 40°C, while for very hot climates, it is - 5°C to + 50°C. At altitudes up to 1000 metres, the preferred minimum ambient temperatures for the low - temperature test are - 10°C, - 25°C, - 30°C, and - 40°C. In outdoor applications, the design of vacuum circuit breakers must account for rapid temperature changes. In India, numerous locations in regions such as Kashmir, Himachal Pradesh, Uttarakhand, and Sikkim encounter such temperature variations.

Temperatures can drop as low as -25°C. In such locations, issues related to cold conditions are exacerbated by frequent occurrences of phenomena like wind chill and snow blizzards. During summer, in many parts of India, temperatures can soar up to 50°C. Manufacturers exporting circuit breakers to countries that experience extremely low or high temperatures need to determine the performance of their products under these extreme climatic conditions.

This paper delves into the performance of 36 kV - class outdoor vacuum circuit breakers (VCBs) under simulated environmental conditions in accordance with IEC 62271 - 100. The tests discussed herein include (a) the low - temperature test and (b) the high - temperature test. Additionally, the paper explores the operating time, the time difference between poles, and the charging time of the operating mechanism for a 36 kV - class outdoor VCB.

To gain an understanding of the performance of outdoor VCBs under low - temperature conditions, the procedure specified in IEC - 62271 - 100 was adopted as a reference. This IEC standard stipulates that for single - enclosure circuit breakers with a common operating mechanism, three - phase tests shall be carried out. For multi - enclosure circuit breakers with independent poles, testing of one complete pole is allowed. In cases where test facility limitations exist, multi - enclosure circuit breakers may be tested using one or more of the following alternatives, provided that the circuit breaker's mechanical operating conditions in the test setup are not more favorable than normal conditions:

- Reduced pole spacing

- Reduced number of modules

- Reduced phase - to - earth insulation

During the test, any maintenance, part replacement, or readjustment of the circuit breaker is prohibited. Unless the circuit breaker's design necessitates a heat source, the liquid or gas supplies for the circuit breaker should be at the test air temperature.

The following operating characteristics of the breaker should be tested:

- Closing time

- Opening time

- Time difference between poles

- Time spread between units of one pole (if multi - pole tested)

- Recharging time of the operating device

- Consumption of the control circuit

- Consumption of tripping devices and recording of shunt releases

- Duration of closing and opening command impulses

- Tightness test if applicable

- Gas pressure if applicable

- Resistance of the main circuit

- Time - travel chart

These characteristics shall be recorded at:

- rated value of supply voltage and rated filling pressure

- maximum value of supply voltage and max filling pressure

- maximum value of supply voltage and min. filling pressure

- Minimum value of supply voltage and minimum filling pressure

Pressure - changed parameters are not applicable for VCBs since the contactor is housed in vacuum bottles and this vacuum interrupter assembly is encapsulated in air - insulated porcelain housing for outdoor application.

The test sequence for low - temperature test is defined in cl. 6.101.3.3 of IEC 62271 - 100. Initial operating characteristics [1.4] are characterized after exposing the breaker at 20 ± 5°C. After initial examination with the circuit breaker in closed position the temperature will be decreased to the minimum ambient air temperature as per the temperature category. The breaker will be kept in closed position for 24 hours with anti - condensation heaters on. After 24 hours the breaker is opened & closed at rated values of supply voltage. The opening and closing time are recorded to establish low - temperature operating characteristics. Then supply to anti - condensation heaters is disconnected for a period of time (t₁) as specified by the manufacturer, subject to a minimum of two hours. During this interval, alarms are admissible but lockouts are not admissible. After time t₁ the breaker is opened and the opening time is recorded. If possible, the mechanical travel characteristics are also measured to allow assessment of interrupting capacity.

The breaker will be in open position for 24 hours after which the breaker will be closed and opened. Then 50 CO operations are performed with the first three CO operations performed without any delay. Balance CO operations are performed as C - tₑ - O - tₑ. Time tₑ is the time period between operations. A 3 - minute interval will be allowed for each cycle or sequence. After completion of 50 CO operations the temperature of the climatic test chamber is raised at the rate of 10 K/hour. During the transition period, C - tₑ - O - tₑ and O - tₑ - C - tₑ - O operations are performed such that the breaker remains in closed and open position for 30 minutes period between the operating sequences. After the circuit breaker stabilizes to ambient temperature a repeat measurement of the operating characteristics is carried out at 20 ± 5°C for comparison with the initial characteristics at 20 ± 5°C.

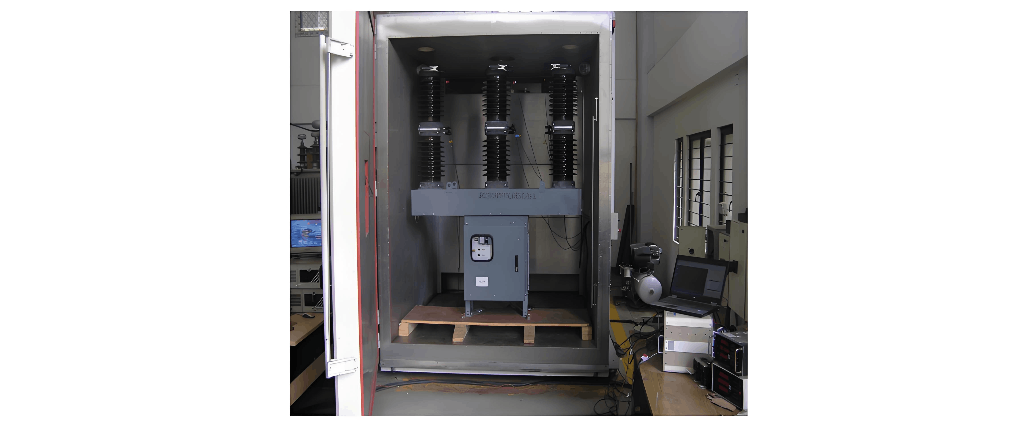

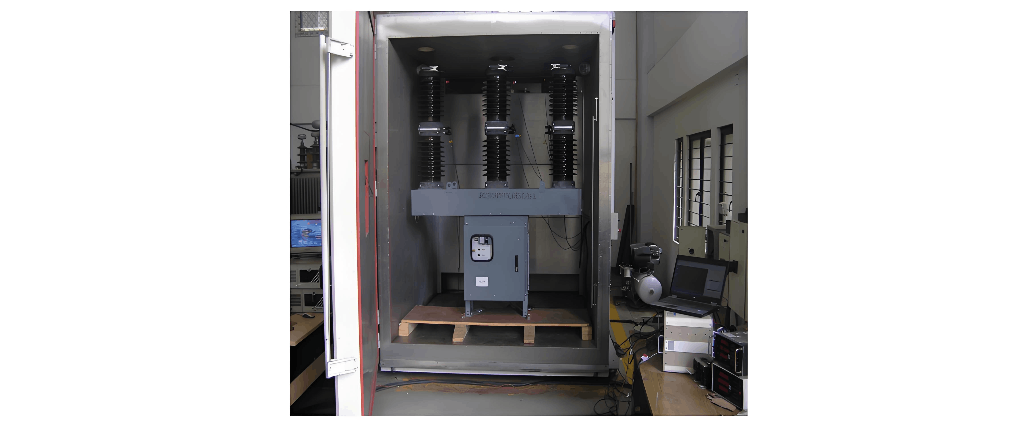

CPRI has been conducting low - and high - temperature tests on Medium High Voltage (MHV) switchgear up to 36 kV for over ten years. Figure 1 shows a typical test arrangement for an outdoor 36 kV vacuum circuit breaker (VCB) installed in the test chamber for high - and low - temperature testing.

Experimental results for a 36 kV - class outdoor VCB during low - and high - temperature tests are presented. The VCBs tested were equipped with spring operating mechanisms.

The high - temperature test was performed at +55°C, and the low - temperature tests were performed at -10°C and -25°C. The following characteristics were examined to analyze the performance of the VCB:

Closing and Opening time (Operating Time):Closing time is defined as the interval of time between energizing the closing circuit, with the circuit breaker in the open position, and the instant when the contacts touch in all poles.Opening time of a circuit breaker is defined as the interval of time between the instant of energizing the opening release, with the circuit breaker in the closed position, and the instant when arcing contacts separate in all poles.

To obtain volumetric data, the average value of the operating times of all three poles is considered for comparison purposes. Since the time spread between poles has been compared, the maximum change between the maximum and minimum time of individual poles is automatically represented.

- a) Time Spread between poles

- b) Characteristic of the recharging device, such as recharging time and current consumption.

- c) Change in operating characteristics in reference to the initial operating characteristics.

The performance of the breakers during high - and low - temperature tests has been compared with reference to the above - mentioned characteristics, and the results are discussed in the subsequent sections.

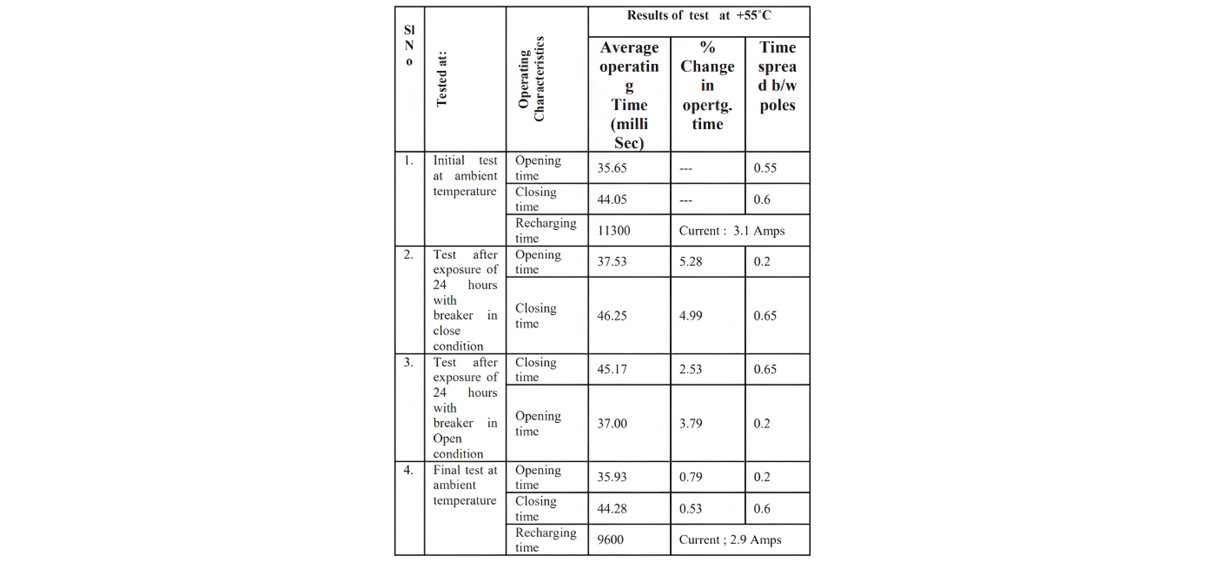

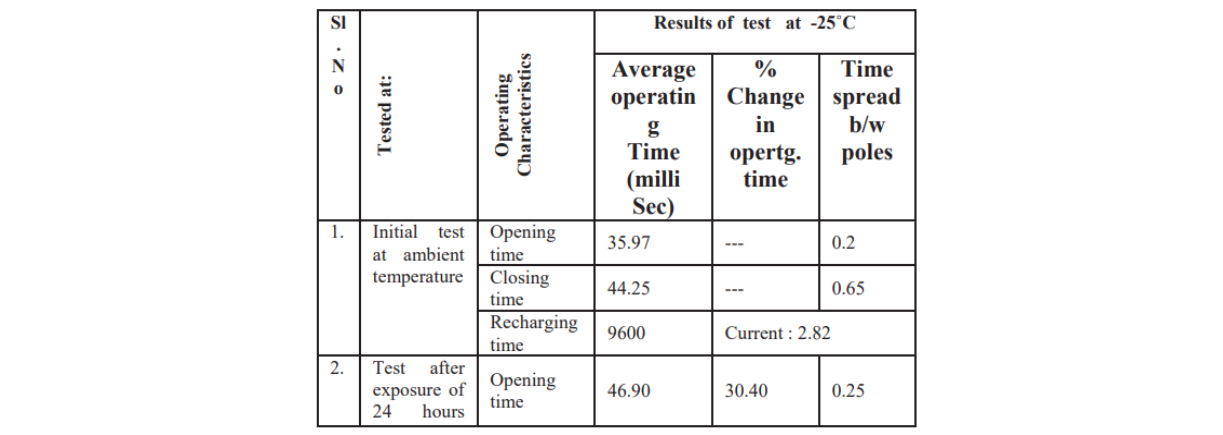

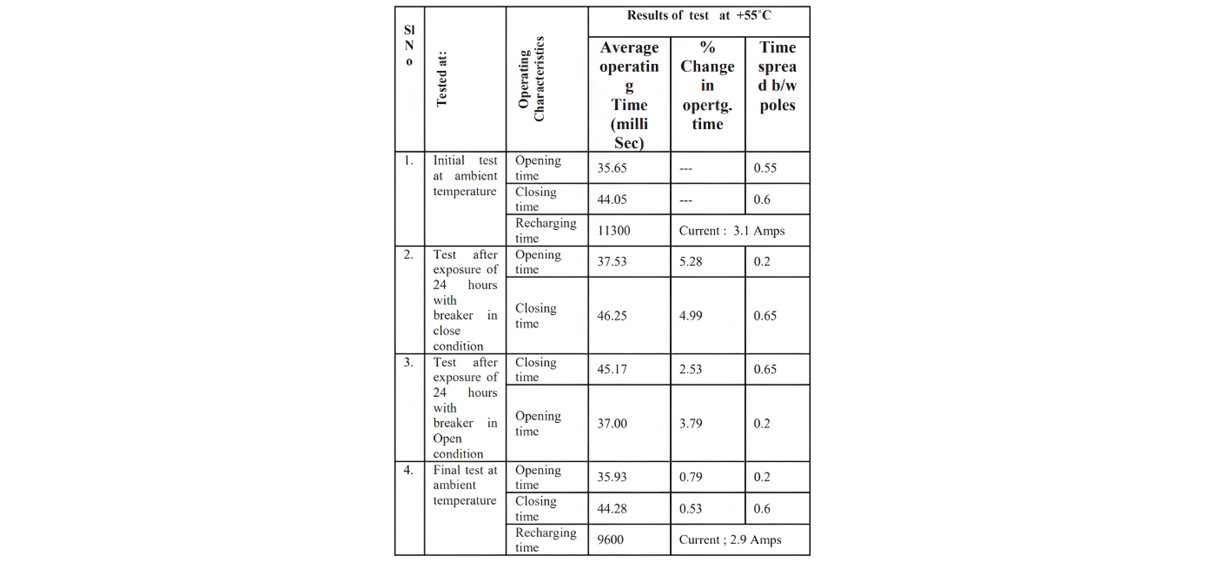

The results of the high - temperature test are presented in Table 1. Initial characteristics were measured at 20°C. IEC 62271 - 100 does not specify any value for operating time or closing time. The measured initial opening times are about 36 ms, and the closing time is around 44 ms. Similarly, the recharging time of the operating device ranges from 9.6 sec to 11.3 sec, and the recharging current is in the range of 2.8 A to 3.1 A.

After 24 hours of exposure to 55°C with the breaker in the closed position, the opening time and closing time uniformly increased by about 5%. After a further 24 - hour exposure to 55°C with the breaker in the open position, the closing time increased by about 2.5%, and the opening time increased by 4%.

There was no significant change in the time spread between poles for all three test samples during the entire test. Hence, it can be inferred that the behavior is similar in all the poles of the VCB.The recharging time decreased from 11.3 sec to 9.6 sec, but the current changed from 2.9 A to 3.4 A.

When comparing the opening and closing times between the initial and final values at ambient temperatures, a change of less than 1% in the operating time was observed, which is negligible.

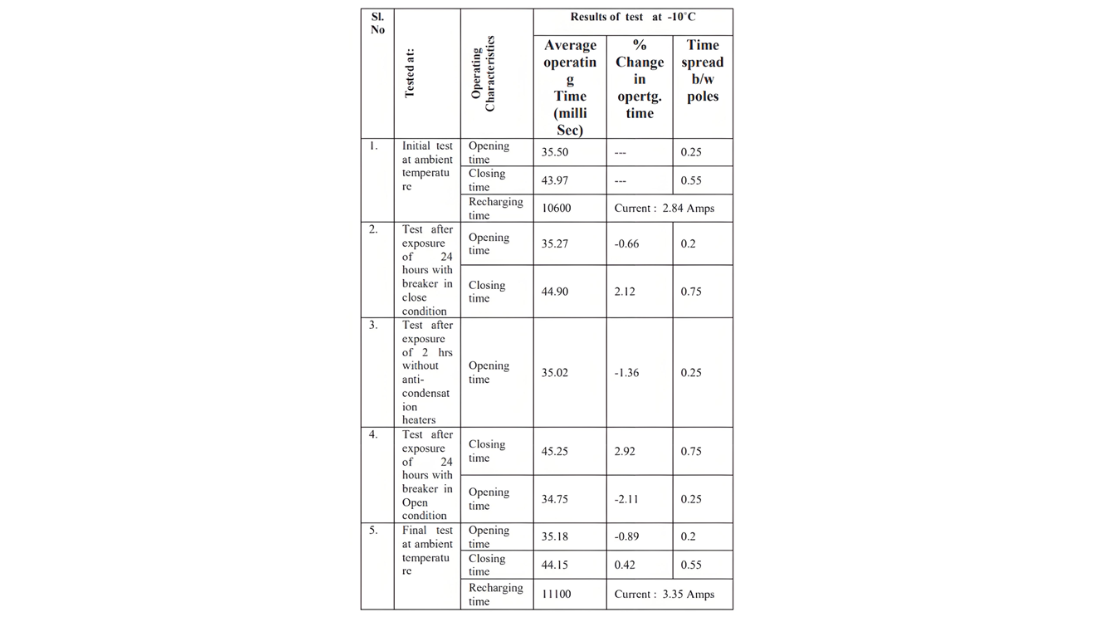

The initial operating characteristics were measured at 20°C. The measured initial values of the opening time were around 36 ms, and the closing time was 44 ms. Similarly, the recharging time of the operating device was 10.6 sec, and the recharging device current was 2.8 A.

After 24 hours of exposure to -10°C with the breaker in the closed position, the opening time decreased by about 0.7%, and the closing time increased by about 2%, with no significant change.

During the two - hour period without anti - condensation heaters, the opening time decreased by 1.36%.After a further 24 hours of exposure to -10°C with the breaker in the open position, the closing time increased by about 3%, and the opening time has decreased by about 2%.

During the final test at ambient temperature, the change was less than 1%. Throughout the entire low - temperature test period at -10°C, there was no significant change in the time spread between poles.

The performance of the breaker at various temperatures, starting from +55°C, -10°C, and -25°C, is presented in Table 1.

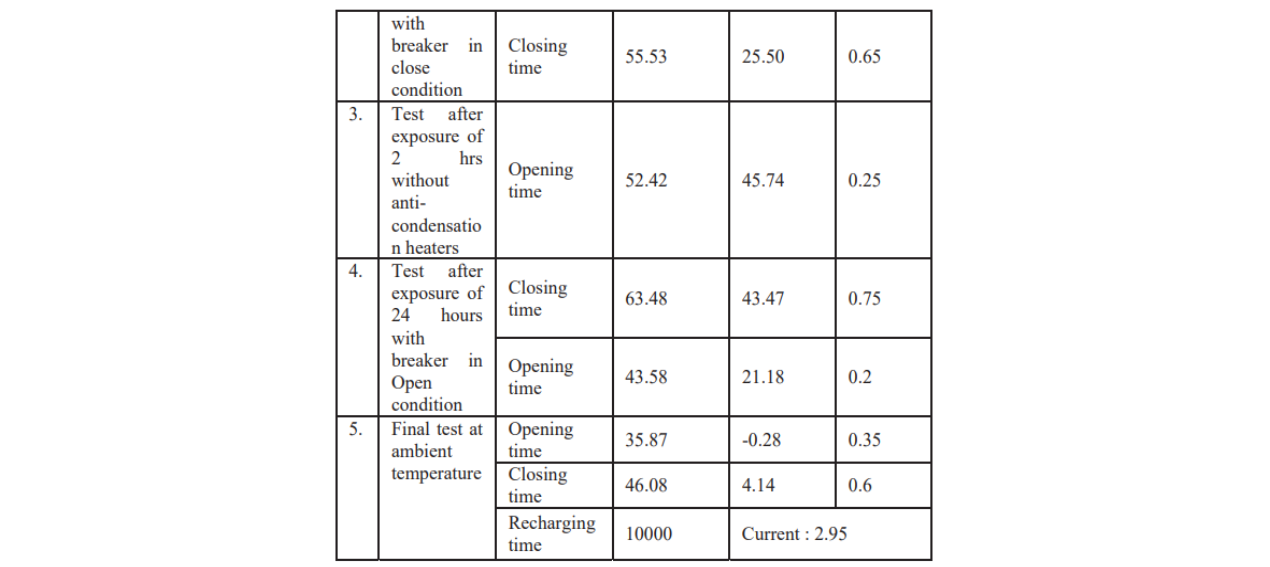

Significant changes in operating time were observed when the breaker operated at a low temperature of -25°C. The results in Table 3 indicate that the breaker exhibited sluggishness during opening and closing at -25°C. The percentage change in operating time at -25°C was notably different. After 24 hours of exposure, the opening time increased by 30%, and the closing time increased by approximately 25%. Similarly, after the anti - condensation heating elements were turned off for two hours, the opening time increased by 46%. Further exposure for 24 hours at -25°C with the breaker in the open position and the anti - condensation heating element supply restored led to a 44% increase in the opening time and a 21% increase in the closing time. The timing graphs for closing time and opening time recorded during the test clearly show these changes.

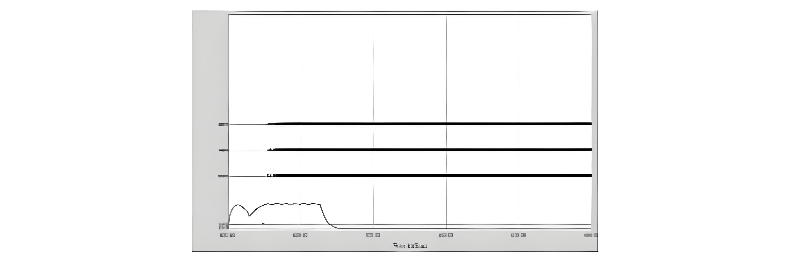

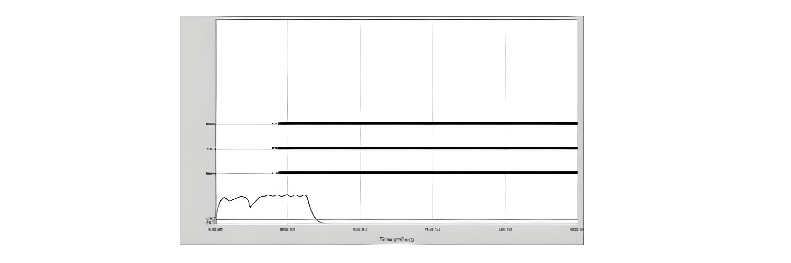

The test at an ambient temperature of 20°C is shown in Figure 2. The timing graphs of the closing time recorded after 50 hours of exposure at -25°C are provided in Figure 3. When compared, the sluggishness of the breaker at -25°C is clearly evident.

When compared with its performance at -10°C, where the change in operating time was only around 0.5% to 3%, the breaker's characteristics at -25°C have deteriorated significantly. At -25°C, the operating - time changes during various stages of the test reached approximately 45%.

This paper presents the experimental results of comparing the performance of 36 kV - class outdoor vacuum circuit breakers (VCBs) during low - and high - temperature tests in accordance with IEC 62271 - 100.

The key findings of this paper are as follows:

- During the high - temperature test at 55°C, the outdoor VCBs performed satisfactorily. The observed changes in operating time and time spreads between poles were insignificant.

- During the low - temperature test at -10°C, the changes in operating time and time spread between poles were insignificant.

- Significant changes in operating time were observed when the breaker operated at a low temperature of -25°C. The observed changes in opening time ranged from 20% to 46%, and changes in closing time were in the range of 25% to 43%.

- The tests conducted indicate that even if an outdoor VCB can operate normally at -10°C, there is no guarantee that it will perform the same in colder conditions such as -25°C. Thus, it is essential to verify its performance at the required low temperature.