How can I determine the number of turns per coil and wire size for a transformer?

How can I determine the number of turns per coil and wire size for a transformer?

Determining the number of turns and wire size for transformer coils requires considering voltage, current, frequency, core characteristics, and load requirements. Below are the detailed steps and formulas:

I. Define Basic Transformer Parameters

Input/Output Voltage (V1,V2): Primary and secondary voltages (in volts).

Rated Power (P): Transformer capacity (in VA or watts).

Operating Frequency (f): Typically 50 Hz or 60 Hz.

Core Parameters:

Core material (e.g., silicon steel, ferrite)

Effective core cross-sectional area (A, in m²)

Maximum flux density (Bmax, in T)

Total magnetic path length (le, in m)

II. Calculate Coil Turns

1. Turns Ratio Formula

Where N1 and N2 are the turns of the primary and secondary coils.

2. Voltage per Turn Calculation

Using Faraday’s Law of Induction:

Rearranged to solve for N:

Parameters:

V: Coil voltage (primary or secondary)

Bmax: Maximum flux density (refer to core material datasheets, e.g., 1.2–1.5 T for silicon steel)

A: Effective core cross-sectional area (in m²)

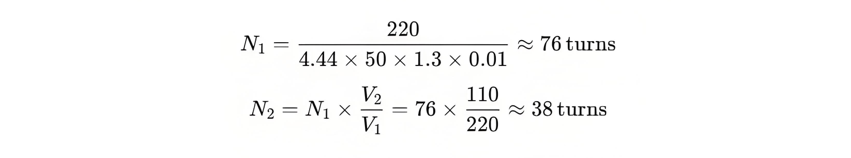

Example:

Design a 220V/110V, 50Hz, 1kVA transformer with a silicon steel core (Bmax=1.3T,A=0.01m2):

III. Determine Wire Size

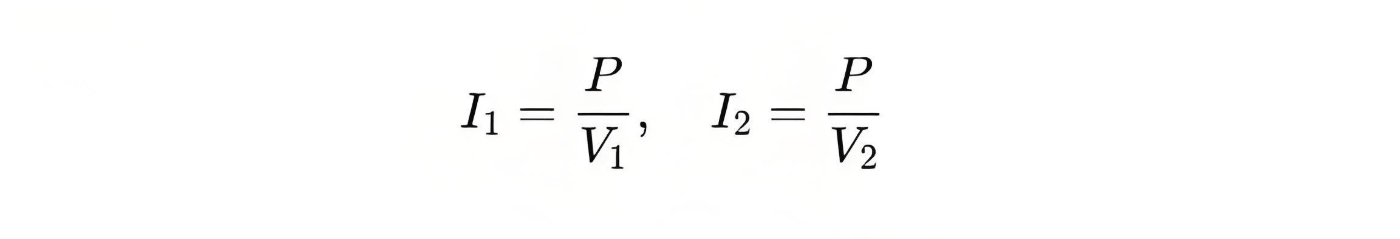

1. Calculate Coil Current

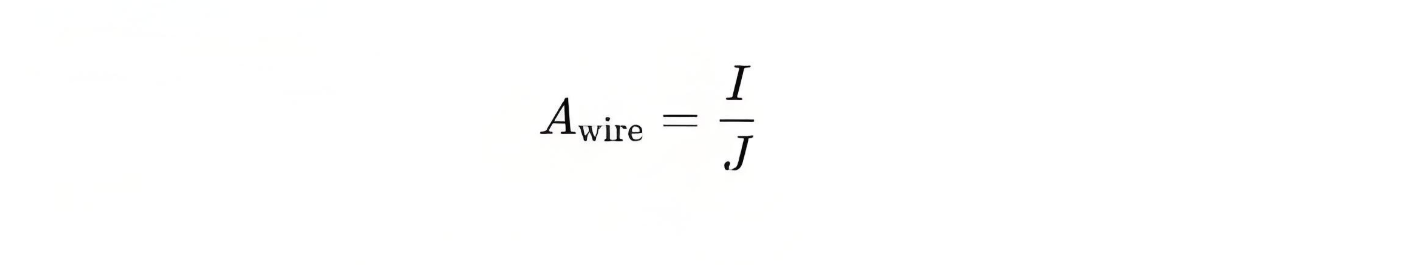

2. Wire Cross-Sectional Area Calculation

Based on current density (J, in A/mm²):

Current Density Guidelines:

Standard transformers: J=2.5∼4A/mm2

High-frequency or high-efficiency transformers: J=4∼6A/mm2 (account for skin effect)

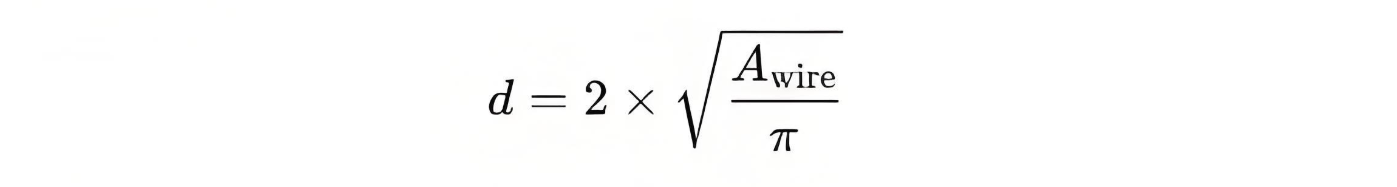

3. Wire Diameter Calculation

IV. Validation and Optimization

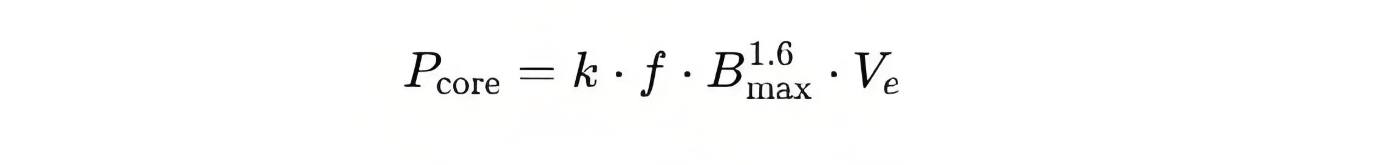

Core Loss Validation:

Ensure the core operates within safe Bmax limits to avoid saturation:

(k: Material coefficient, Ve: Core volume)

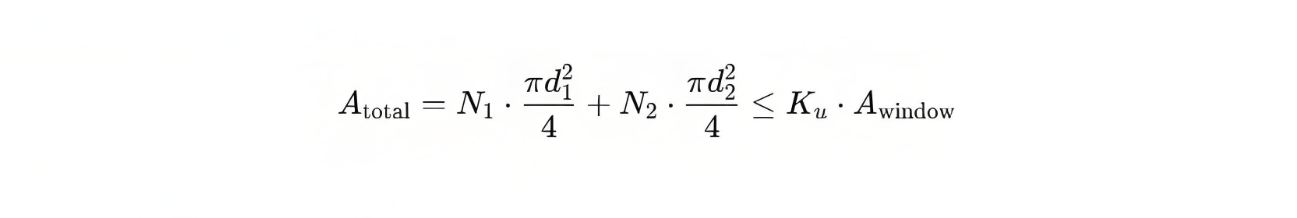

Window Area Utilization:

Total wire cross-sectional area must fit within the core’s window area (Awindow):

(Ku: Window fill factor, typically 0.2–0.4)

Temperature Rise Check:

Ensure wire current density meets temperature rise requirements (typically ≤ 65°C).

V. Tools and References

Design Software:

ETAP, MATLAB/Simulink (for simulation and validation)

Transformer Designer (online tool)

Guides and Standards:

Transformer Design Handbook by Colin Hart

IEEE Standard C57.12.00 (General Requirements for Power Transformers)

Key Considerations

High-Frequency Transformers: Address skin and proximity effects using Litz wire or flat copper strips.

Insulation Requirements: Ensure insulation withstands voltage between windings (e.g., ≥ 2 kV for primary-secondary insulation).

Safety Margin: Reserve a 10–15% margin for turns and wire size.

This methodology provides a foundation for transformer design, but experimental testing is recommended for final validation.

The Electricity Encyclopedia is dedicated to accelerating the dissemination and application of electricity knowledge and adding impetus to the development and innovation of the electricity industry.