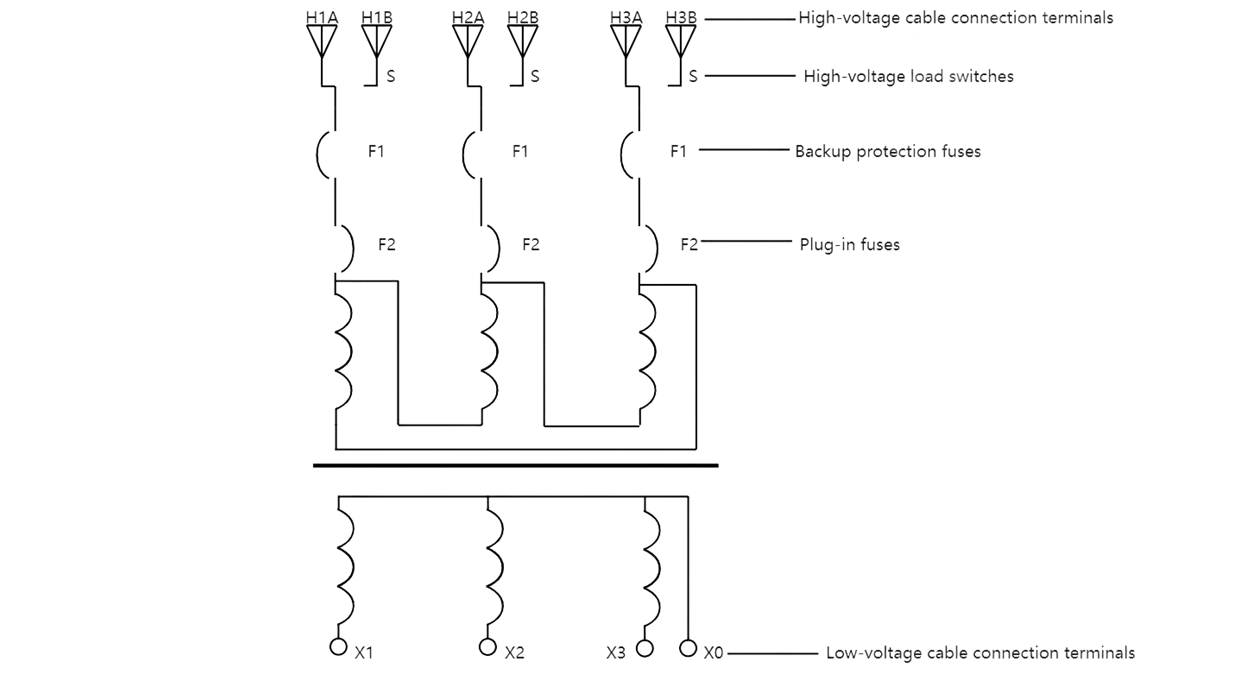

Electrical Principle and Structure of Pad-Mounted Substations

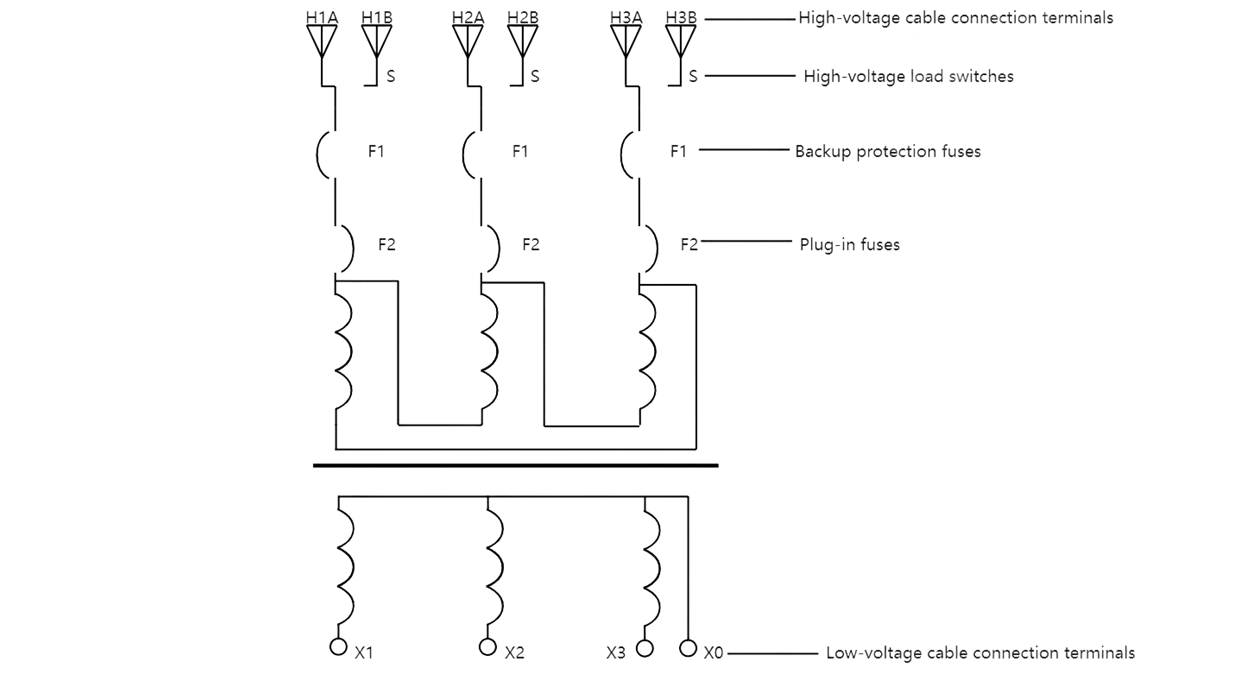

The electrical schematic diagram of the pad-mounted substation is shown in Figure 1.

Structural Composition:

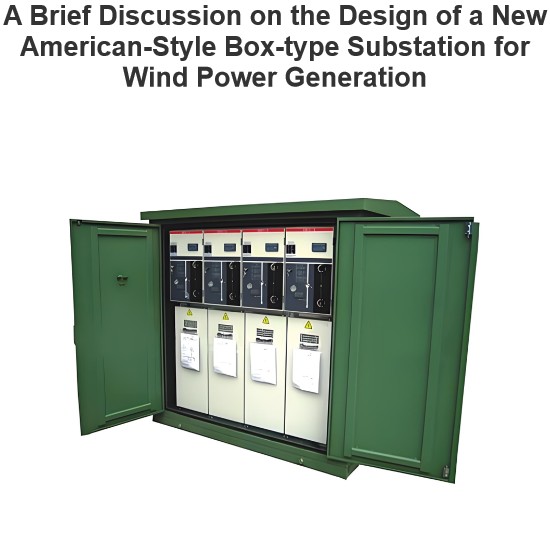

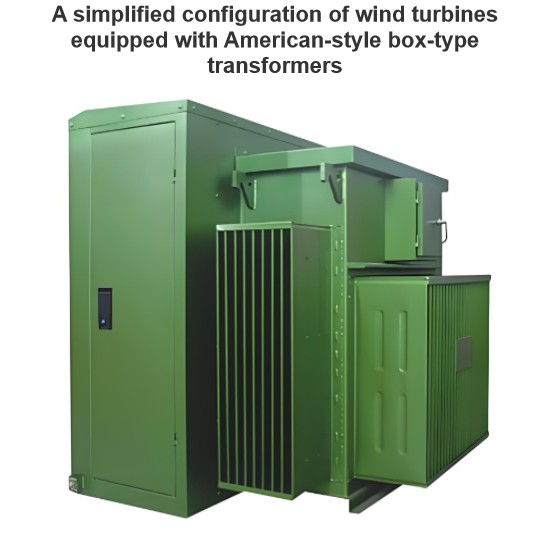

An American-style pad-mounted combined substation is primarily composed of a pad-mounted transformer, structured into front and rear sections:

- Front Section (Wiring Cabinet): Contains high/low-voltage terminal blocks, a high-voltage load switch, plug-in fuses, a high-voltage tap changer operating handle, a pressure gauge, an oil level gauge, an oil thermometer, etc.

- Rear Section (Oil Tank and Radiators): Houses the transformer’s core, windings, high-voltage load switch, and plug-in fuses within a fully sealed oil tank. The transformer body typically adopts a three-phase five-leg core design, which can be a wound core or laminated core made of high-quality cold-rolled grain-oriented silicon steel sheets or high-efficiency amorphous alloy sheets. The low-voltage windings use a foil structure, enhancing the transformer’s resistance to short circuits, lightning impulses, and overloads. The connection group is Dyn11.

- Sealed Structure: The tank’s fully sealed design ensures protection. Oil-immersed load switches are available in multiple types to meet the requirements of radial or ring main distribution systems.

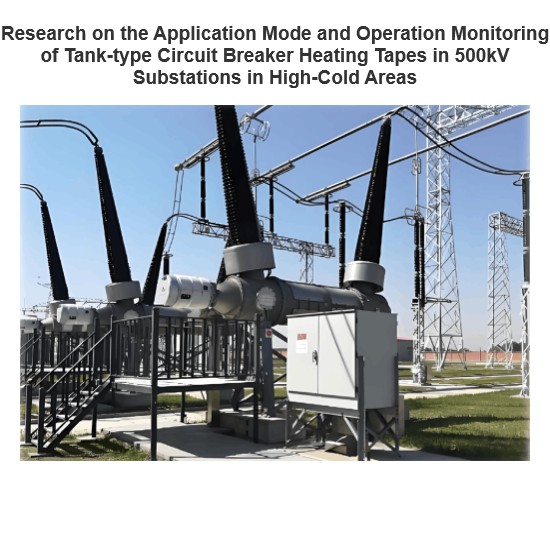

Protection and Structure of American - style Pad - mounted Substations

American - style pad - mounted substations are protected by a series connection of a backup fuse protector and a plug - in fuse. The backup fuse protector operates only when a fault occurs in the pad - mounted substation, safeguarding the high - voltage line. The plug - in fuse, with dual - sensitive fuses, blows when short - circuit faults, overloads, or excessive oil temperatures occur on the secondary side. This protection method is economical, reliable, and easy to operate.

The high - voltage terminals of the pad - mounted substation are equipped with bushing sockets, single - pass bushing connectors, and elbow (bent) - type cable connectors capable of handling a 200 A load. The live parts are sealed within insulators, creating a fully insulated structure where the terminal surface is not electrified, ensuring personal safety. Additionally, a plug - in composite - insulated metal - oxide arrester can be installed on the elbow - type insulator bushing. This arrester is fully shielded, fully insulated, and plug - and - play, ensuring safety and facilitating easy installation. Accessories such as live indicators and fault indicators can also be added.

Characteristics of Pad - mounted Transformers

Pad - mounted transformers, a new type of transformers widely used in recent years, are characterized by reliable power supply, reasonable structure, rapid and flexible installation, convenient operation, small size, and low cost. They can be used both outdoors and indoors, and are thus widely applicable in various scenarios such as industrial parks, residential communities, commercial centers, and high - rise buildings. Compared with domestic pad - mounted substations, American - style pad - mounted substations have the following advantages and characteristics:

- Compact Size: Their volume is approximately one - third of that of domestic pad - mounted substations of the same capacity.

- Fully Sealed and Insulated: With a fully sealed and insulated structure, there is no need for insulation clearances, ensuring personal safety and making them suitable for underground power distribution environments.

- Versatile Application: They can be used in both ring - main and terminal applications, with convenient conversion, enhancing power supply reliability.

- Strong Overload Capacity: They can withstand an overload of 2 times the rated value for 2 hours or 1.6 times for 7 hours without affecting their service life.

- Low Loss: Their losses are lower than those of domestic S₉ - type transformers.

- Flexible Cable Connectors: The cable connectors can handle a 200 A load current. In emergency situations, they can function as load switches and also have the characteristics of disconnect switches, providing convenient and flexible operation.

- Dual - Fuse Protection: The use of dual - fuse protection reduces operating costs. The fuses in the plug - in fuses are dual - sensitive (to temperature and current).

- High - Flash - Point Oil: Using high - flash - point oil (R - TEMP oil with a flash point as high as 312°C), they can be placed inside buildings without the risk of fire hazards.

- Corrosion Resistance: The transformer body is designed for anti - corrosion and treated with special paint, making it suitable for various harsh environments, such as areas with frequent storms and high pollution.

- Superior Electrical Performance: Thanks to the Δ/Υ connection and three - phase five - limb structure, they have outstanding advantages such as high voltage quality, stable neutral point, no heating of the body, low noise, and good lightning protection performance.

- Land - Saving: Usually placed in green belts, they save space that would otherwise be used for building power distribution rooms, effectively improving land utilization.

Applications of Pad - mounted Transformers

Selection of Pad - mounted Transformers

- Capacity Selection: Determining the capacity involves factors such as load, investment, losses, and service life. Generally, based on meeting the maximum load with a margin, an economic and technical comparison is made among transformers of similar capacities to select the distribution transformer with the lowest total cost of ownership. The rated capacities of American - style pad - mounted substations include 150, 225, 300, 500, 750, 1000, 1500, and 2000 kVA.

- Type Selection: Pad - mounted substations are classified into terminal type and ring - main type, mainly determined by the type of load switch.

- Installation Location: There are two types of insulating oil in pad - mounted substations. One is common mineral oil, such as domestic No. 25 transformer oil; the other is R - TEMP oil (high - flash - point oil with a flash point of 312°C). Pad - mounted substations filled with R - TEMP oil (with a clear mark on the low - voltage side) can be used inside buildings, while those filled with common oil cannot.

- Customization of Low - Voltage Side: American - style pad - mounted substations generally do not come with low - voltage branch protection and metering. However, branch protection switches, metering instruments, and compensation devices can be added on the low - voltage side according to user requirements.

Engineering Application Example

A unit in Kunming urban area, which has newly built residential buildings and office buildings, selected a pad - mounted transformer from American COOPER Company. The transformer model is PMT - LO - 500, with a rated capacity of 500 kVA and a rated voltage of 10 kV/0.4 kV. On the low - voltage side, three current transformers, one voltmeter, three ammeters, and four - way load - outlet air switches were added according to the requirements of users and the power supply department. COOPER's fully insulated, maintenance - free cable branching boxes that can withstand any harsh environment and allow load - break plugging and unplugging were installed on both sides of the pad - mounted substation to supply power to each building. The pad - mounted substation and the branching boxes were placed in the green belt, harmonizing well with the environment. After more than a year of operation, both the power supply department and users have reported good results.

Precautions for Use

When selecting and using pad - mounted substations, attention should be paid to the type of pad - mounted substation, the type of load switch, and user requirements for low - voltage meters.

- Types of Pad - mounted Substations: There are ring - main type and terminal type. For ring - main type pad - mounted substations, the load switch can be switched to supply high - voltage power to the other end.

- Types of Load Switches: Load switches are divided into 2 - position type, 3 - position type, and 4 - position type. Each position type has several forms. For example, the 4 - position type includes T - type and Y - type, both of which can be used for dual - power supply. The T - type can be used in ring - main pad - mounted substations, while the Y - type can only be used in terminal pad - mounted substations.

- Inspection of Plug - in Fuses in Newly Installed Pad - mounted Substations: When checking the plug - in fuses of newly installed pad - mounted substations, it is necessary to note whether the pressure gauge of the pad - mounted substation indicates zero. If the pressure gauge does not indicate zero, the exhaust valve should be toggled to exhaust air first before plugging or unplugging the fuses. Otherwise, transformer oil may spray out.

Conclusion

Pad - mounted transformers are essential electrical equipment for urban power grid renovation, real - estate development, and residential power supply construction. American - style pad - mounted substations have become the first choice for urban power distribution transformers due to their unique features and prices comparable to domestic counterparts. With their convenient use and numerous advantages, they have received high praise from society and users, and have become the development direction for small - scale urban substations.